Dimensional Tolerance & Surface Finish: The Ultimate Guide

了解精度如何影响密封环、喷嘴、模具等的性能。

精度基础知识:公差、表面光洁度及其重要性

了解影响零件配合和功能的关键概念:尺寸公差、表面光洁度以及精度在实际应用中的作用。

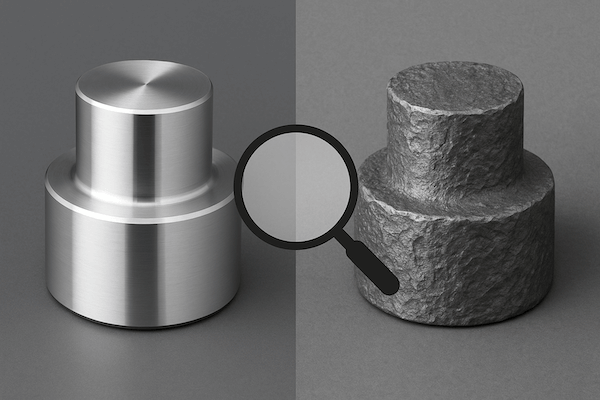

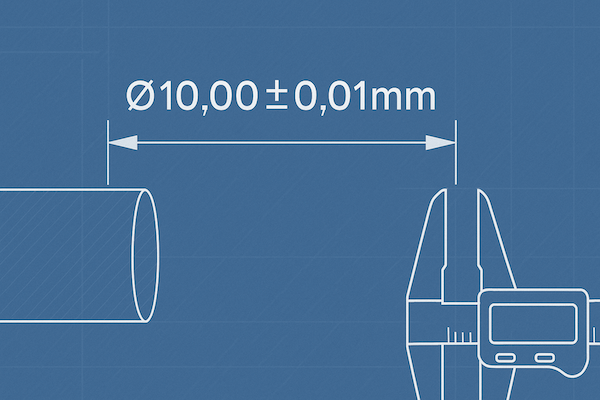

什么是尺寸公差?

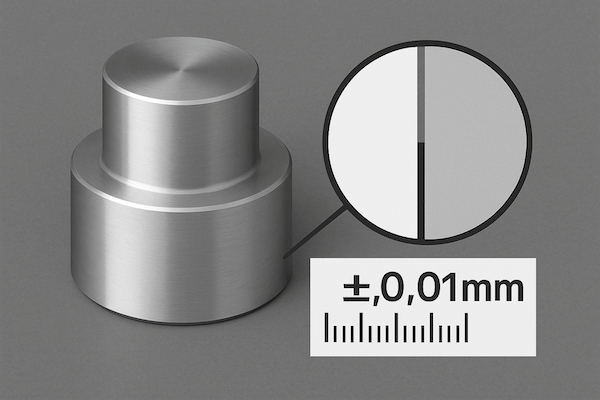

尺寸公差告诉我们尺寸与图纸可以有多少偏差。这就好比说:“这个零件应该是10毫米,但稍微多一点或少一点都没问题——可能是±0.01毫米。”

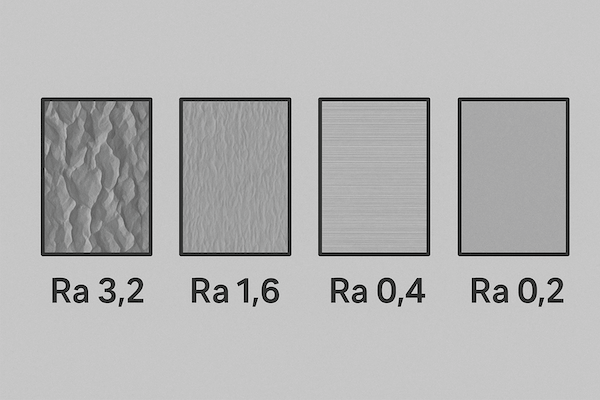

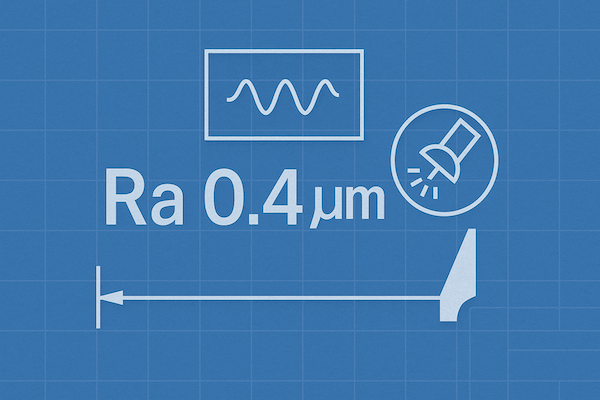

什么是表面光洁度?

表面光洁度告诉我们表面的光滑程度。它以 Ra(平均粗糙度)来衡量。Ra 值越低,表面越光滑。Ra 值越高,表面越粗糙。

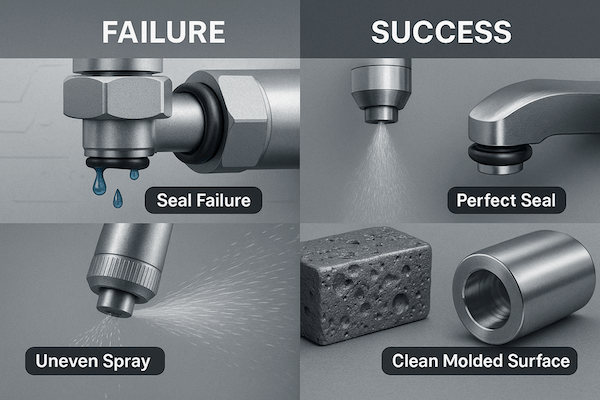

为什么精度在实际使用中很重要

精度不仅仅关乎数字——它决定了密封件是否泄漏,喷嘴喷射是否笔直,或者模具能否生产出完美的零件。公差或表面光洁度不佳会导致早期故障或性能下降。

如何在图纸上指定公差和表面光洁度

清晰标注尺寸公差,例如“Ø10.00 ±0.01mm”。并添加表面光洁度符号,例如 Ra 0.4µm。如不确定,请咨询供应商。

明确标记公差

务必清晰地写出允许的尺寸范围。例如:Ø10.00 ±0.01mm。这能告诉工厂零件的精度要求。

添加表面粗糙度符号

不知道该写什么?问问你的供应商。好的供应商会帮你选择合适的公差和表面光洁度。

有疑问时,请询问

精度不仅仅关乎数字——它决定了密封件是否泄漏,喷嘴喷射是否笔直,或者模具能否生产出完美的零件。公差或表面光洁度不佳会导致早期故障或性能下降。

表面光洁度等级和常见应用

不同的Ra值决定了表面的光滑程度。此图表显示了典型的表面处理及其应用场景。

| 镭(微米) | 描述 | 常见用途 |

|---|---|---|

| 3.2 | 粗糙的 | 铸件,粗铣 |

| 1.6 | 正常机加工表面 | 通用车削/铣削 |

| 0.8 | 精加工 | 精密轴 |

| 0.4 | 非常顺畅 | 模具、密封面 |

| 0.2 | 镜面般 | 密封圈、光学元件 |

关于公差和表面光洁度的常见问题

这些是客户在准备图纸或订购精密零件时最常提出的问题。清晰的答案可以帮助您避免代价高昂的错误。

问题 1:如果我不指定公差会怎样?

将使用标准加工公差,这可能无法满足您的确切需求。

Q2:我怎么知道我需要什么 Ra?

这取决于部件的功能。如不确定,请联系我们——我们会推荐最佳级别。

问题3:Retop 能达到 Ra 0.2µm 吗?

是的,我们提供精密抛光服务,以实现超光滑的表面。

问题4:我可以对同一张图纸的不同部分要求不同的公差吗?

是的,您可以为不同的特征指定不同的公差。只需确保它们在图纸上清晰标注即可。

问题 5:如果我的图纸仅显示尺寸但没有 Ra 或公差,会发生什么情况?

我们将遵循标准的加工和精加工规范,但结果可能与您的性能预期不符。如有任何疑问,请务必说明。

问题6:表面光洁度如何影响工具性能或寿命?

更光滑的表面可以减少摩擦和磨损,从而提高密封性、流动性和整体寿命,特别是对于高精度部件。