Tungsten carbide (WC) bushings are essential components in machinery that require high strength and 耐磨性. However, they are not immune to performance issues, particularly when noise and vibration arise.

These problems can lead to early wear, reduced efficiency, and potential failure of the machinery. Identifying the root causes of noise and vibration is critical for the maintenance of WC bushings.

This field checklist will help you troubleshoot common issues related to noise and vibration affecting WC bushings, offering solutions to improve performance and extend service life.

Understanding the Impact of Noise and Vibration on WC Bushings

Noise and vibration are not just indicators of machinery malfunction; they also directly affect the lifespan of tungsten carbide bushings.

These issues typically arise due to mechanical stress, misalignment, or poor lubrication. Over time, prolonged exposure to noise and vibration can result in excessive wear, cracks, or even complete failure of the bushing.

为什么重要:

Increased Wear: Excessive vibration can cause the bushing to wear unevenly, leading to performance issues.

Heat Build-Up: Vibrations generate heat, which can degrade the lubrication and increase friction.

Early Failure: If not addressed, noise and vibration can result in premature failure of the bushing.

Identifying the Causes of Noise and Vibration in WC Bushings

Understanding the potential causes of noise and vibration is essential to diagnosing the problem and taking corrective action.

1). Common Causes:

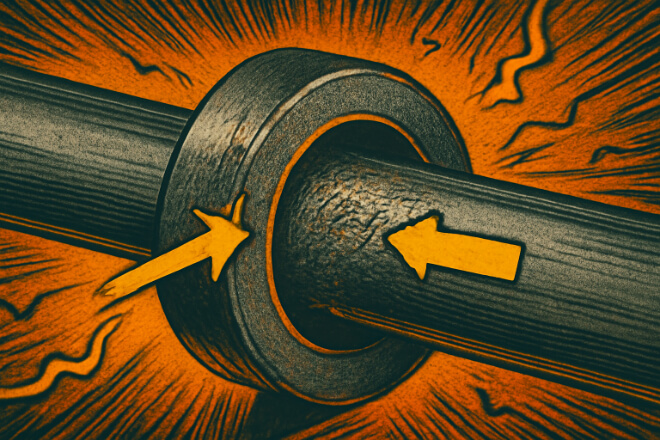

Misalignment: When the shaft and bushing are not properly aligned, uneven wear and vibration can occur.

Improper Clearance: Too tight or too loose a fit between the bushing and shaft can cause movement that results in noise and vibration.

Inadequate Lubrication: Insufficient lubrication increases friction, which leads to vibrations and noise.

Excessive Load: When the bushing is subjected to loads beyond its capacity, vibrations are often amplified.

Wear and Tear: Over time, the bushing may wear out, leading to irregularities in the surface that cause noise and vibrations.

2). How to Spot the Issue:

Excessive Noise: A high-pitched or grinding sound often indicates friction, misalignment, or wear.

Frequent Vibration: Continuous or irregular vibrations may signal improper clearance or damage.

Field Checklist: How to Inspect for Noise and Vibration Issues

A structured inspection can help detect noise and vibration problems before they lead to failure. Here’s a step-by-step checklist to identify and solve issues:

1). Check for Misalignment

Misalignment between the shaft and bushing can cause uneven pressure on the bushing surface, leading to vibrations and noise.

Action: Use a laser alignment tool or a dial indicator to check for shaft misalignment.

Solution: Adjust the alignment of the shaft to bring it into correct alignment with the bushing.

2). Inspect for Proper Clearance

Incorrect clearance can cause either excessive friction or unstable movement, both of which result in vibration and noise.

Action: Measure the gap between the bushing and shaft using feeler gauges or micrometers.

Solution: Adjust the clearance to fall within the manufacturer’s specified tolerance.

3). Lubrication Check

Improper or insufficient lubrication is one of the most common causes of increased friction, leading to noise and vibration.

Action: Inspect the lubrication system to ensure the correct type and amount of lubricant is being used.

Solution: If necessary, replace or top up the lubricant and ensure proper lubrication is flowing.

4). Inspect for Excessive Load

Too much load on the bushing can create vibrations and noise due to the increased stress on the bushing and shaft.

Action: Verify the operational load using the equipment’s specification sheets.

Solution: Reduce the load to the recommended limits to prevent excessive stress on the bushing.

5). Check for Surface Wear

Wear on the bushing surface can cause irregularities that result in noise and vibration during operation.

Action: Visually inspect the bushing for any signs of surface damage or roughness.

Solution: If surface wear is found, consider replacing the bushing or polishing the surface for smoother operation.

| Cause | Symptoms | Action | 解决方案 |

|---|---|---|---|

| Misalignment | Uneven wear, grinding noise | Check alignment with laser or dial indicator | Realign shaft and bushing |

| Improper Clearance | Excessive friction, vibration | Measure clearance with feeler gauges or micrometer | Adjust clearance to recommended tolerance |

| Inadequate Lubrication | Increased friction, heat, noise | Inspect lubrication levels and flow | Replace or top up lubricant |

| Excessive Load | Vibration, heat build-up | Check load specifications | Reduce load to recommended level |

| Surface Wear | Rough surfaces, irregular motion | Visually inspect bushing for wear | Polish or replace the bushing |

Preventing Noise and Vibration Problems

While detecting and addressing noise and vibration is important, prevention is always the best approach. Here are several strategies for minimizing noise and vibration in WC bushings:

1). Regular Maintenance

Perform regular inspections of the bushing and shaft to catch any issues early. Regular lubrication, alignment checks, and wear inspections can prevent problems from escalating.

2). Proper Shaft and Bushing Compatibility

Ensure that the materials and dimensions of the shaft and bushing are compatible. Mismatched components can lead to excessive friction and vibrations.

3). Use Vibration Dampening Systems

In high-vibration environments, consider installing vibration dampeners or isolators to absorb excess vibrations before they reach the bushing.

4). Avoid Overloading

Ensure that the system is not overloaded and always operates within the recommended specifications to prevent unnecessary stress on the bushing.

结论

Noise and vibration issues in tungsten carbide bushings are common problems that can lead to premature failure if not addressed.

By following a structured checklist to inspect for misalignment, improper clearance, inadequate lubrication, excessive load, and surface wear, you can prevent these issues and extend the life of your WC bushings.

Regular maintenance, proper alignment, and compatible materials are key to maintaining optimal performance.

如果您想了解任何公司的更多详细信息,请随时 联系我们。