石油和天然气行业面临着世界上最严酷的工作条件之一。深层钻探、岩石切割以及生产线维护都需要坚固可靠的刀具。碳化钨刀具正是为此而生。这些刀具以其卓越的硬度、耐磨性和长寿命而闻名,已成为现代石油和天然气作业的重要组成部分。

在这篇博客中,我们将探讨碳化钨如此有效的原因、它在现场的使用方式,以及为什么它仍然是在苛刻的钻井和开采环境中工作的公司的明智选择。

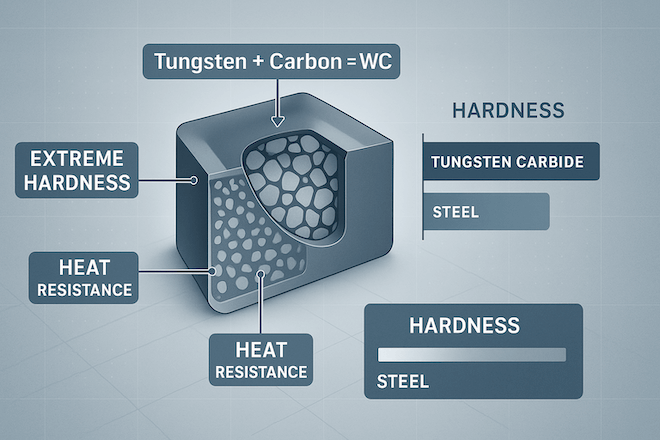

什么是碳化钨?

碳化钨是一种由钨和碳结合而成的硬质材料。这种化合物比钢硬得多,即使在恶劣条件下也能保持锋利。碳化钨常用于制造切割、钻孔、研磨或成型其他材料的工具。

它在 石油和天然气工业 因为它可以承受高压、高温和高磨损环境,而不会快速破裂或磨损。

为什么石油和天然气作业需要高性能工具

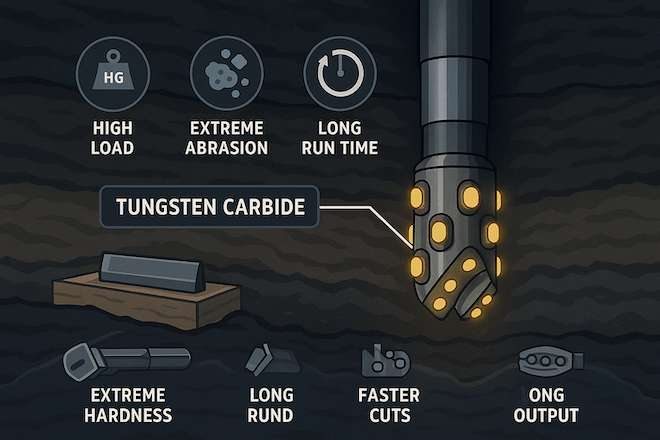

钻穿岩石、沙子和页岩对工具的要求极高。传统的钢制工具磨损很快,导致停机和更换成本。 碳化钨切削刀具 提供更好的解决方案,因为它们使用寿命更长,并且可以在极端条件下继续工作。

这对于井下工具、钻头和海底组件尤其重要,因为工具故障可能导致昂贵的延误和生产损失。

油田环境中的应用

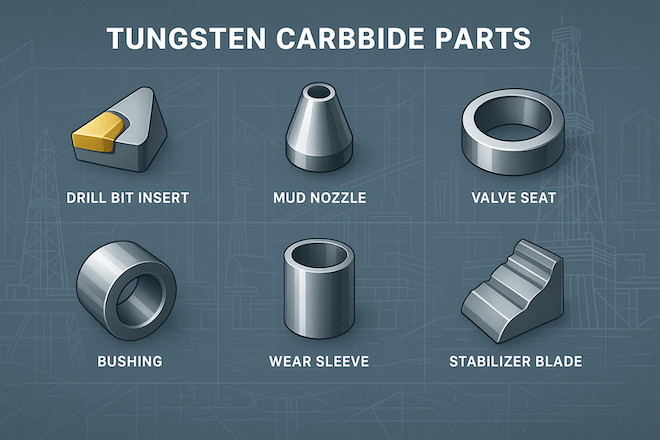

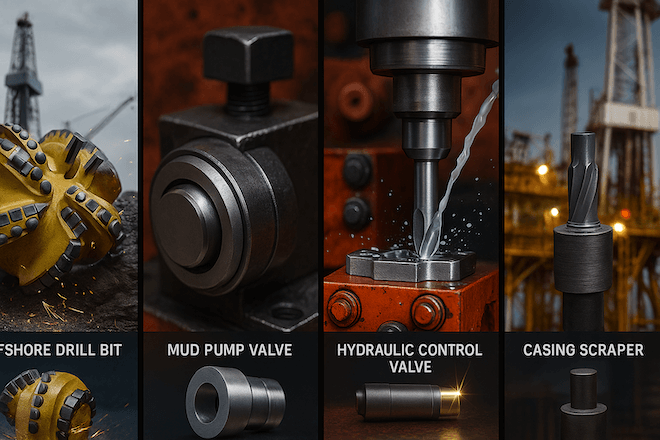

碳化钨工具用于石油和天然气生产的各个部分:

陆上和海上钻井平台的钻头

水力压裂系统中的泵部件

阀门和节流阀 高压流体控制

管道开沟切割头

套管刮刀在井筒清洁中的应用

每种应用都需要强度、准确性和长使用寿命——碳化钨可以提供这些品质。

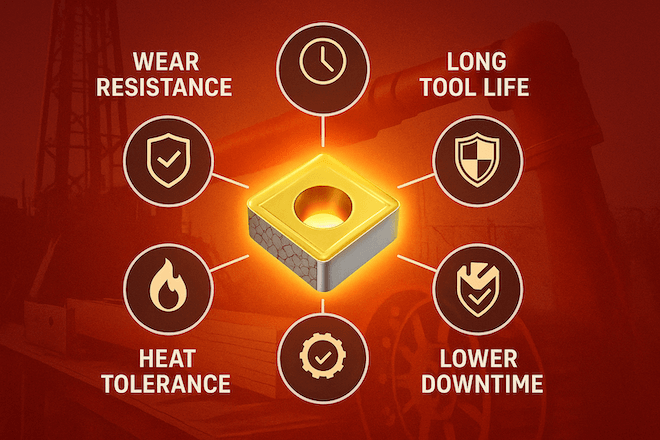

石油和天然气决策者为何选择碳化钨

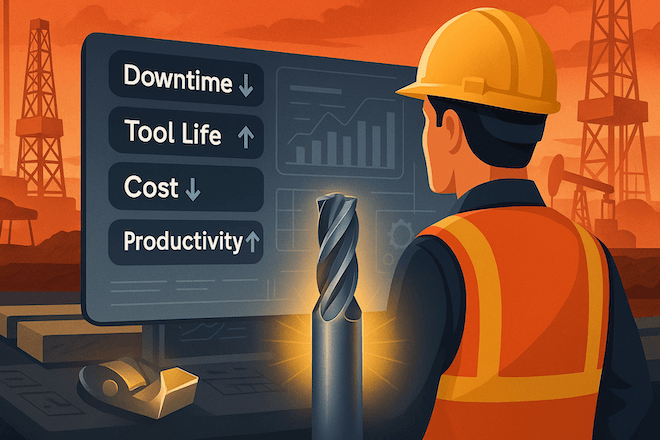

对于石油和天然气行业的管理人员和工程师来说,目标很简单:确保运营顺利进行,并尽可能减少停机时间。碳化钨刀具通过降低刀具更换频率、提高切削速度和降低更换成本来帮助实现这一目标。

通过选择高性能材料,决策者可以提高效率和盈利能力。

结论

石油天然气行业依赖坚固、精准、耐用的工具来应对当今的挑战。碳化钨工具能够提供所需的性能,实现更深的钻进、更长的运行时间和更高的产量,同时还能降低成本并减少停机时间。对于希望提升工具性能的决策者来说,碳化钨仍然是明智的选择。

如果您正在为石油和天然气作业寻找高性能碳化钨工具,请考虑与值得信赖的供应商合作,例如 雷托普 提供定制解决方案和专家支持。