碳化钨切削刀具 强大、快速、可靠——但选择合适的并不总是那么容易。

由于种类、涂层和用途如此之多,感到不知所措是正常的,特别是如果您不是工具专家。

在本指南中,我们将向您详细讲解如何根据工作需求选择合适的碳化钨切削刀具。无论您是进行钻孔、铣削还是车削,您都将学习如何更明智地选择刀具,以获得更佳的加工效果。

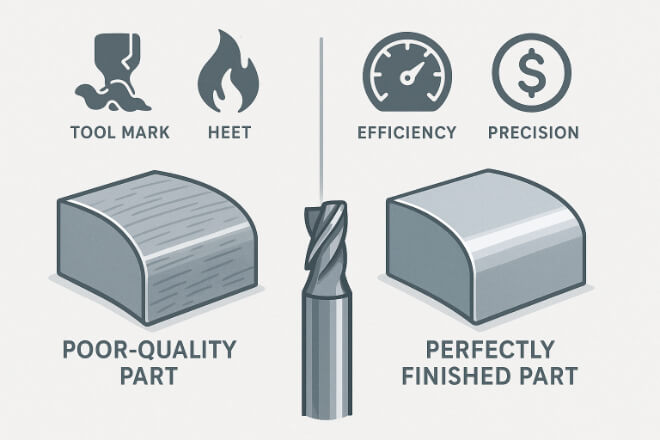

1. 为什么选择正确的工具很重要

切削刀具看似不起眼,但其影响却举足轻重。错误的刀具可能会导致表面粗糙、刀具断裂、过热,甚至损坏您的数控机床。而合适的碳化钨刀具则能为您提供以下优势:

切割平滑准确

更长的刀具寿命

减少机器停机

更好的表面光洁度

降低每个零件的成本

简而言之,选择正确的工具可以提高您的加工质量和利润。

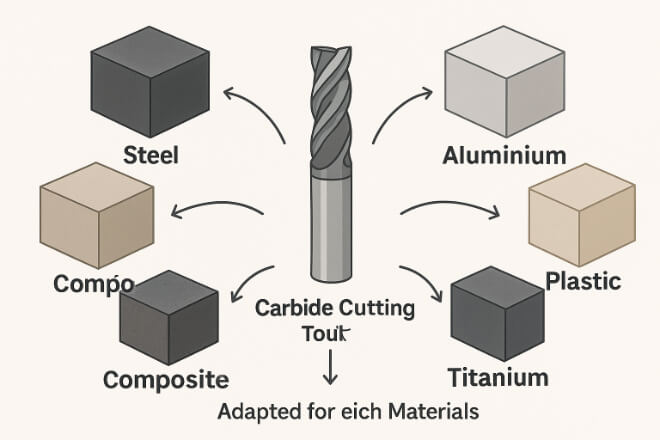

| 材料类型 | 工具需要什么 |

|---|---|

| 铝、铜 | 锋利的边缘、抛光的凹槽、高转速、更少的凹槽 |

| 钢、不锈钢 | 坚固的芯体、耐热涂层、适度的进给 |

| 钛、因科镍合金 | 非常坚韧的硬质合金材质,慢进给,涂层刀具 |

| 塑料、复合材料 | 几何形状,不粘涂层,低热量 |

| 石材、陶瓷 | 极硬的碳化物,坚固的设计,坚固的机身 |

在坚硬或粘性材料上使用错误的工具可能会快速磨损边缘或导致破损。

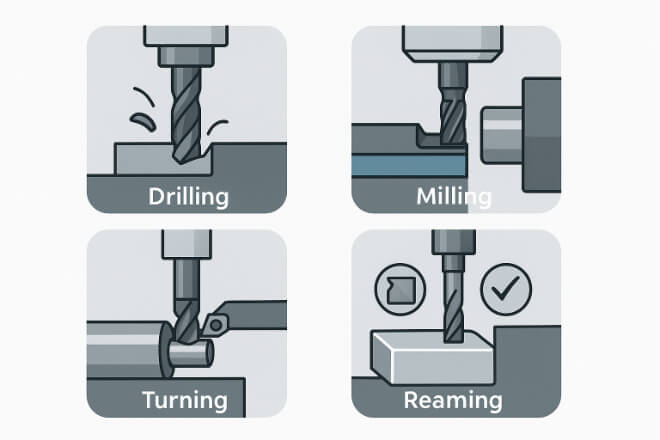

第 2 步:了解加工操作的类型

你用这个工具做什么?钻孔?开槽?还是完成一个部件?

每个操作都需要特定的工具形状和特征:

钻孔:使用整体硬质合金钻头来获得精确的钻孔。寻找钻尖角适合您材料的钻具(例如,对于硬质金属,钻尖角应为 135°)。

铣削:使用刃数合适的立铣刀。加工铝材时使用2刃立铣刀,加工钢材时使用4刃立铣刀。考虑刀尖圆角半径以增加强度。

车削:使用与车床刀架匹配的硬质合金刀片。根据切削深度和表面光洁度选择正前角或负前角。

镗孔、开槽、铰孔:使用具有精细几何形状和稳定柄部设计的硬质合金刀具来加工公差较小的孔。

每个操作都有其理想的工具——选择正确的工具可以节省时间并提高完成度。

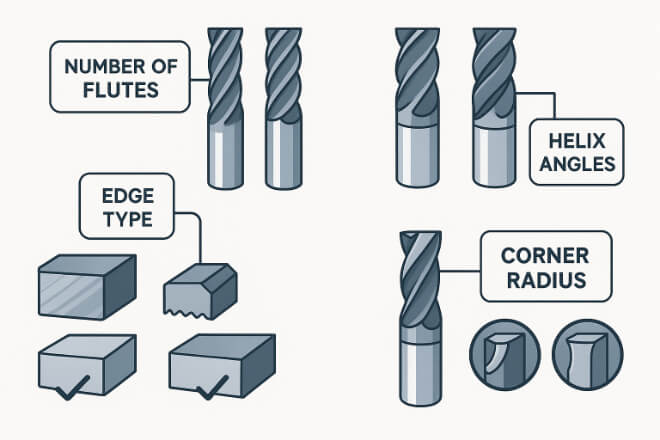

步骤3:选择正确的刀具几何形状

刀具几何形状指的是切削刃的形状和角度。即使是微小的差异也会影响刀具的性能。

1). 主要几何特征:

1.1). 槽数:

2 刃:软金属的最佳排屑空间

4 刃或更多刃:更坚硬材料的表面更加光滑

1.2). 螺旋角:

高(40°+):适用于软金属,表面质量更好

低(20°–30°):对于硬质金属,切削力更大

1.3). 边缘锐度:

锋利:更适合柔软或薄的材料

倒角/圆形:更坚固,在坚硬的金属上使用寿命更长

1.4). 圆角半径:

方角:适合精细工作,但易碎

圆角:减少应力并延长刀具寿命

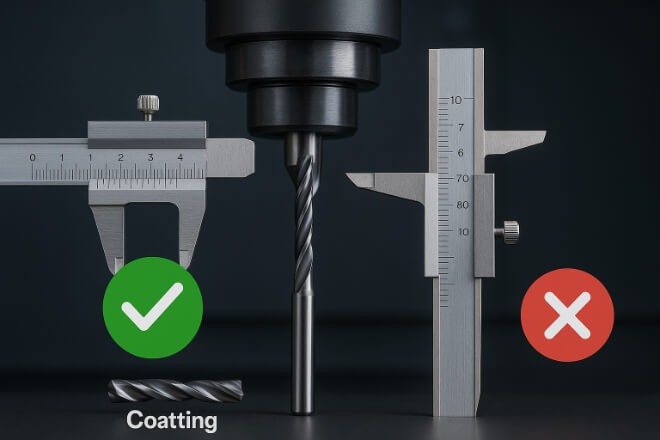

步骤4:选择合适的刀具涂层

良好的涂层可以使刀具寿命延长一倍甚至三倍。它可以减少磨损、散热,并防止材料粘附在刀具上。

碳化钨切削刀具通常采用先进的涂层来增强性能,以使其性能与特定的材料和应用相匹配。

在碳化钨基体上使用正确的涂层可以使工具保持更长时间的锋利并抵抗极端温度。

如果您使用碳化钨工具切割钢或钛,请选择 TiAlN 或 AlTiN。

对于铝或塑料,请寻找抛光或 DLC 涂层的硬质合金工具,以避免材料堆积。

提示:如果您发现碎屑焊接到工具上或表面光洁度变差,则可能需要不同的涂层。

步骤5:将工具尺寸与机器匹配

即使是完美的工具,如果不适合你的机器,也无法正常工作。购买前:

检查主轴转速 (RPM) 与刀具尺寸

确保刀柄适合您的刀架

避免使用太长的工具(它们会引起振动)

确保您的机器具有足够的扭矩来适应刀具直径

使用对于您的设置来说太大或太小的工具可能会导致不良结果甚至损坏您的 CNC 机器。

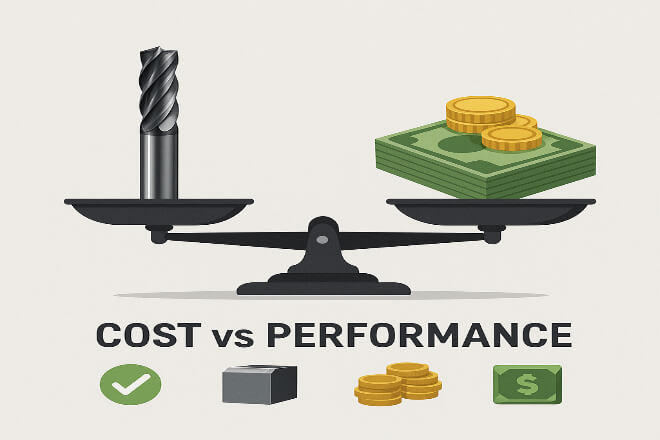

步骤6:平衡刀具寿命和成本

选择最便宜的刀具可能很诱人,尤其是在短线加工中。但请记住:优质的碳化钨刀具使用寿命更长,切割效果更好,并且加工过程更稳定。

思考一下:

该工具可以切割多少个零件?

表面质量重要吗?

更换工具会导致多少停机时间?

重新研磨是一种选择吗?

大多数情况下,多花一点钱买一个好的工具从长远来看可以省钱。

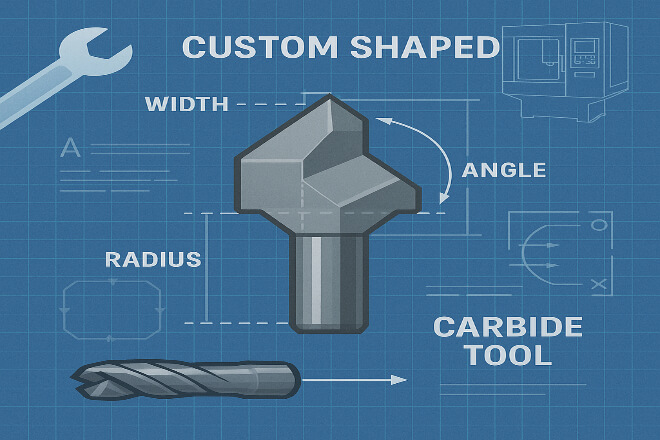

步骤 7:考虑定制工具

如果您要进行特殊加工——例如加工几何形状奇特或材质复杂的零件——您可能需要定制硬质合金刀具。以下情况尤其需要注意:

您需要缩短周期时间

您正在加工特殊材料

标准工具磨损太快

您希望将多个操作组合到一个工具中

9. 应避免的常见错误

避免以下常见错误,选择合适的碳化钨工具会更容易:

对铝等粘性金属使用错误的涂层

工具运行速度对于材料来说太快或太慢

忽略槽数(影响切屑排出)

使用过多或过少的冷却剂

刀具在主轴或夹头中的固定方式不正确

工具的选择不仅仅取决于尺寸,还取决于所有部件如何协同工作。

最后的想法

合适的碳化钨切削刀具可以帮助您提高工作效率、切割更干净,并节省成本。选择合适的刀具主要包括以下几个关键步骤:

了解你的材料

匹配您的操作

选择适当的几何形状

使用正确的涂层

将其安装到您的机器上

平衡性能和成本

需要时进行定制

如果你不确定从哪里开始,或者需要专家建议,请联系 雷托普兹 随时准备提供帮助。

他们的硬质合金工具专为高性能而设计——无论您是刚起步的商店还是运行大批量 CNC 操作。