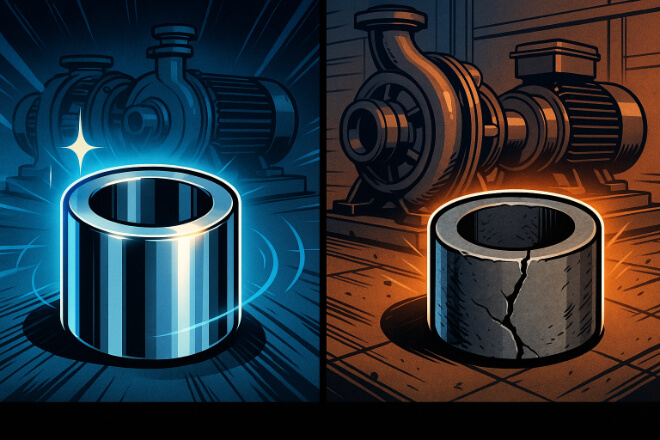

For OEMs and industrial companies, the quality of a tungsten carbide bushing depends heavily on the authenticity of its material.

Poor-quality or mixed-grade carbide can lead to early wear, cracking, leakage, and unexpected downtime.

This guide explains practical methods to verify whether a 碳化钨衬套 is made from true, high-grade materials.

It is written in simple English and designed for decision-makers who need clear and reliable information.

Why Material Authenticity Matters for OEMs

The performance of a tungsten carbide bushing comes mainly from the purity of 碳化钨粉 and the quality of the binder (cobalt or nickel).

If a supplier uses recycled powder, low-purity carbide, or incorrect binder ratio, the bushing will fail earlier than expected.

1). Risks of using non-authentic material

降低 硬度 and faster wear

更高 孔隙度 leading to cracks

Poor chemical resistance

减少 密度

Weak bonding between carbide particles

Shorter service life and more replacements

2). Typical Failure Impact Table

| 问题 | Cause | Effect on Equipment |

|---|---|---|

| Low hardness | Weak binder or recycled powder | Fast wear, shorter lifetime |

| High porosity | Poor sintering quality | Cracks, chipping, leakage |

| Wrong binder ratio | Uncontrolled cobalt/nickel levels | Low toughness or poor corrosion resistance |

Verify Material Through Chemical Composition Testing

Material composition determines hardness, wear resistance, and corrosion resistance. The most reliable way to confirm authenticity is chemical analysis.

1). Common chemical tests

XRF (X-ray Fluorescence): Detects tungsten carbide purity, binder type, and contamination.

ICP-OES / ICP-MS: Gives precise measurement of cobalt, nickel, iron, and other trace elements.

Carbon & oxygen analysis: Shows moisture or oxidation in carbide powder.

2). What OEMs should require

A chemical composition report for every batch

Clear grade statement (e.g., WC-6Co, WC-12Co, WC-Ni)

Zero recycled powder unless approved

Proof that powder source is stable and consistent

If a supplier cannot offer composition reports, authenticity is doubtful.

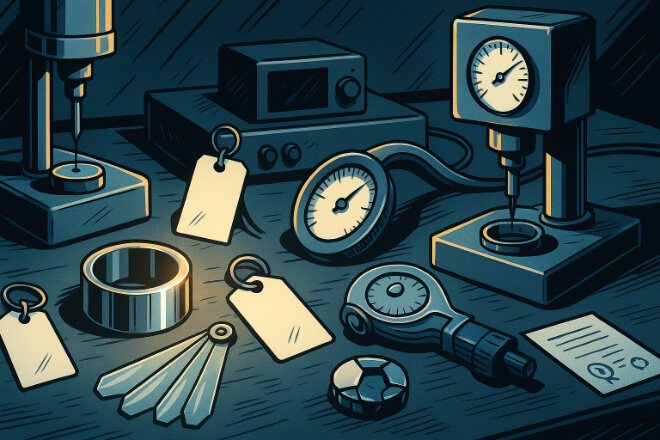

Use Density and Porosity Testing

Tungsten carbide is a high-density material. If density is too low, it means the sintering process was poor or the material is not pure.

1). 密度 testing methods

Archimedes density test (most common)

Hydrostatic weighing

Helium 孔隙度 test (advanced)

2). Typical density values

Standard WC-Co: 14.4–15.0 g/cm³

Low density = high porosity → poor wear life

3). Density Evaluation Table

| 密度(克/立方厘米) | Quality Level | Interpretation |

|---|---|---|

| 14.8–15.0 | 出色的 | Low porosity, correct binder ratio |

| 14.4–14.7 | Acceptable | Normal commercial level |

| Below 14.3 | 贫穷的 | High porosity or mixed materials |

Verify Authenticity Through Hardness Testing

Hardness reveals heat-treatment quality, binder ratio accuracy, and grain structure stability.

1). Hardness expectations

WC-6Co: ~1700 HV

WC-12Co: ~1500 HV

Submicron WC: 1800 HV+

If hardness deviates significantly, the material is not authentic.

2). Typical hardness tests

Vickers 硬度 (HV)

Rockwell A

OEMs should always request hardness data for every batch.

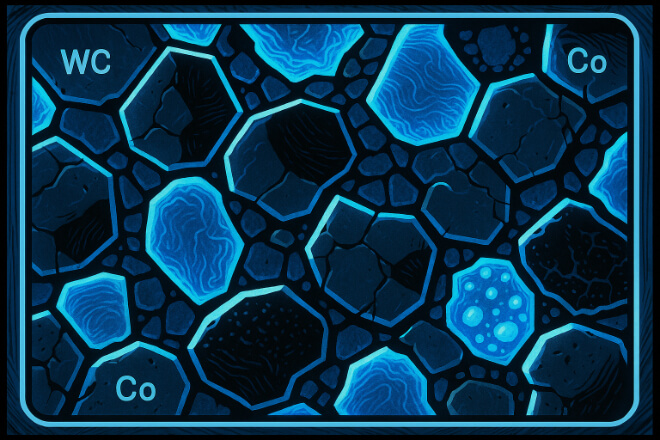

Check Microstructure With Microscopy

一个 碳化钨衬套’s microstructure can reveal whether the raw powder was pure, mixed, recycled, or sintered properly.

1). What inspectors look for

Uniform WC grains

No abnormal grain growth

Even binder distribution

No cracks, pits, or voids

No contamination particles

2). Equipment used

Optical microscope (basic check)

SEM (Scanning Electron Microscope) (detailed analysis)

Microstructure provides the strongest visual proof of authenticity.

Non-Destructive Testing (NDT) for Hidden Defects

NDT methods help detect internal problems that suggest poor-quality or fake materials.

Common NDT methods

Ultrasonic testing – finds internal cracks or voids

Dye penetrant inspection – finds surface defects

Eddy current testing – detects structural differences

If a bushing has many internal defects, the material quality is probably fake or low-grade.

Evaluate Supplier Documentation and Traceability

A strong supplier provides complete documentation and full traceability.

1). Documents that prove authenticity

Material certificate (MTC)

Chemical composition report

密度 report

硬度 report

Microstructure images

NDT test results

Powder batch number and source

2). Traceability Table

| Item | Strong Supplier | Weak Supplier |

|---|---|---|

| Powder source record | Clear and traceable | Not provided |

| Chemical reports | Every batch | Sometimes missing |

| Hardness & density | Full test data | Not detailed |

结论

Verifying the authenticity of tungsten carbide bushings is essential for ensuring long service life and safe equipment operation.

OEMs should check chemical composition, density, hardness, microstructure, NDT results, and supplier documentation.

With the right verification steps, decision-makers can protect their equipment, reduce downtime, and avoid poor-quality products.

如果您想了解任何公司的更多详细信息,请随时 联系我们。