Tungsten carbide products are widely used in many industries because of their high 硬度, durability, and 耐磨性.

They are found in tools, 磨损件, 阀门, seals, and many precision components. However, the growing demand has also brought a problem: fake or low-quality products are entering the market.

For decision-makers in industries such as mining, oil and gas, automotive, electronics, or manufacturing, using poor-quality tungsten carbide parts can lead to machine failures, production downtime, higher costs, and even safety risks.

That is why it is important to know how to verify the authenticity of tungsten carbide products before making a purchase.

This article will explain practical steps, testing methods, and supplier checks you can use to make sure the tungsten carbide products you buy are real and reliable.

Why Authenticity Matters

Authentic tungsten carbide products guarantee performance and long service life. If the product is fake or made with poor raw materials, it may:

Break or wear out too quickly

Cause damage to expensive machines

Increase downtime and maintenance cost

Fail to meet safety or performance standards

For decision-makers, verifying authenticity is not only about quality control.

It is also about protecting your investment, ensuring production efficiency, and building long-term trust with suppliers.

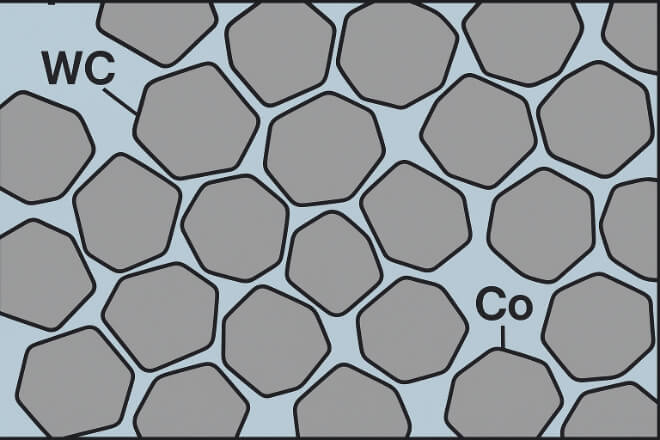

Step 1: Check Material Composition

The most important part of tungsten carbide authenticity is the material composition. Genuine products are made from:

Tungsten carbide grains (WC)

Cobalt or nickel binder (Co/Ni)

Poor-quality or fake products often contain higher porosity, mixed cheap metals, or low binder ratios. This reduces hardness and toughness.

How to check:

Request a material certificate from the supplier.

Look for details such as binder percentage, WC grain size, and density.

Compare with standard industry grades like YG6, YG8, or ISO grades.

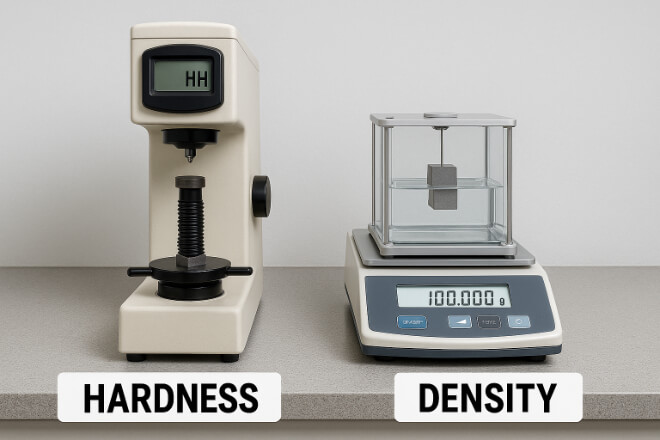

Step 2: Verify Density and Hardness

Two of the easiest ways to test authenticity are 密度 和 硬度.

Genuine tungsten carbide has density around 14.5 – 15.0 g/cm³.

Hardness is usually HRA 89.5 – 92.5 depending on grade.

How to check:

Ask for density reports (Archimedes method).

Review hardness testing results (Rockwell or Vickers).

Compare values with industry standards.

If density is too low, the product may contain voids or inferior filler metals. If hardness is outside the range, it may be a different material.

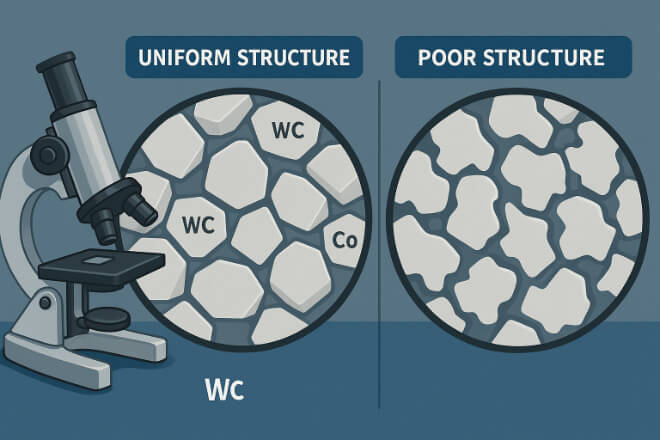

Step 3: Inspect Microstructure

A professional way to check authenticity is to look at the microstructure under a microscope.

Genuine tungsten carbide shows uniform WC grains evenly distributed in the binder.

Fake products may show large uneven grains, porosity, or cracks.

You can ask for:

Microscope images from the supplier’s lab.

Independent third-party lab tests if order value is high.

Step 4: Review Manufacturing Standards

Trusted manufacturers follow strict quality systems. Before buying, check:

ISO 9001 certification or equivalent

Industry-specific approvals (e.g., API for 石油和天然气, 汽车 quality standards)

Traceability records for raw powder and finished parts

If a supplier cannot provide these, it may be a red flag.

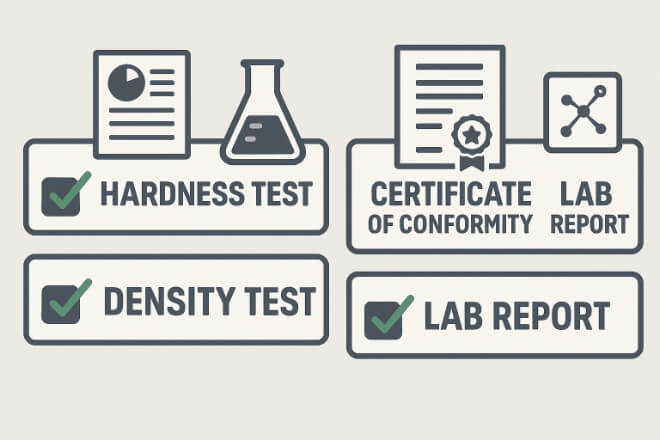

Step 5: Look for Testing and Certification

Authentic tungsten carbide products should come with test reports and certificates. These may include:

Decision-makers should always request these documents. A lack of reports may indicate poor-quality or fake products.

Step 6: Check Dimensional Accuracy

Another sign of authenticity is precision machining and tight tolerance.

Tungsten carbide products are usually ground to ±0.002 mm tolerance.

Surfaces are polished or lapped to Ra 0.02 – 0.05 µm.

Poor-quality products often have:

Rough surfaces

Loose tolerances

Dimensional mismatch

This leads to fitting problems and machine wear. Always verify the supplier’s measurement reports or inspection data.

Step 7: Ask for Case Studies or References

A genuine supplier will have real customers and case studies. Ask for:

References from similar industries

Application case studies

Photos or videos of their products in use

This helps you confirm that their tungsten carbide products perform well in real-world applications.

Step 8: Evaluate Supplier Reputation

One of the strongest signs of authenticity is supplier credibility. Look for:

Years of experience in tungsten carbide manufacturing

Export history and global customer base

Reviews or testimonials

Transparent communication and technical support

For decision-makers, building partnerships with suppliers who are proven in the industry reduces risk and saves cost in the long term.

Step 9: Consider Independent Testing

For critical applications, it is wise to send samples to a third-party laboratory for testing. They can confirm:

Independent results give you peace of mind that the products are genuine and safe for use.

Step 10: Be Aware of Red Flags

Some warning signs that a tungsten carbide product may not be authentic:

Very low price compared to market average

Supplier cannot provide certificates or test reports

No clear company background or certifications

Inconsistent communication and slow responses

Poor product packaging and labeling

Decision-makers should always avoid taking risks with suppliers that show these red flags.

结论

Verifying the authenticity of tungsten carbide products is essential for decision-makers in industries where precision, durability, and safety are critical.

By checking composition, density, hardness, microstructure, certifications, and supplier reputation, you can protect your company from fake or poor-quality products.

Making the right choice not only ensures better performance but also reduces downtime, lowers costs, and builds long-term reliability in your operations.

如果您想了解任何公司的更多详细信息,请随时 联系我们。