Tungsten carbide tips are known for their 硬度 和 耐磨性, making them a preferred choice for cutting tools in various industries.

However, the performance of tungsten carbide can be further enhanced with coatings.

These coatings not only improve the durability of the tips but also increase their resistance to wear, heat, and corrosion.

This blog will explore the benefits of tungsten carbide tip coatings, how they enhance performance, and the types of coatings commonly used in the industry.

Why Coatings are Important for Tungsten Carbide Tips

Tungsten carbide, while extremely hard and 耐磨, can still benefit from additional protection.

Coatings are used to improve the material’s properties, such as resistance to heat, friction, corrosion, and wear.

They provide an extra layer of protection that can significantly extend the life of the tungsten carbide tips.

In industries like mining, manufacturing, and drilling, where tools are subject to extreme conditions, coatings ensure that these tips continue to perform effectively over time.

Types of Coatings for Tungsten Carbide Tips

There are several types of coatings commonly used on tungsten carbide tips. Each type offers different advantages depending on the specific application:

Titanium Nitride (TiN):

This is one of the most popular coatings for tungsten carbide.

TiN provides excellent 硬度, wear resistance, and heat resistance, making it ideal for high-performance cutting tools.

Titanium Carbonitride (TiCN):

TiCN is a variation of TiN and offers even better 耐磨性 and hardness.

It is commonly used for cutting harder materials and in operations where extreme durability is required.

Chromium Nitride (CrN):

CrN coatings provide excellent 耐腐蚀性 and high-temperature stability. They are often used in applications where the tool will be exposed to high levels of heat or corrosive environments.

Diamond-Like Carbon (DLC):

DLC coatings offer superior hardness and low friction, making them ideal for reducing wear and increasing the tool’s lifespan.

These coatings are particularly effective in applications involving abrasive materials.

Aluminum Titanium Nitride (AlTiN):

AlTiN coatings are designed to withstand very high temperatures. They are used in high-speed machining and other operations that generate a lot of heat.

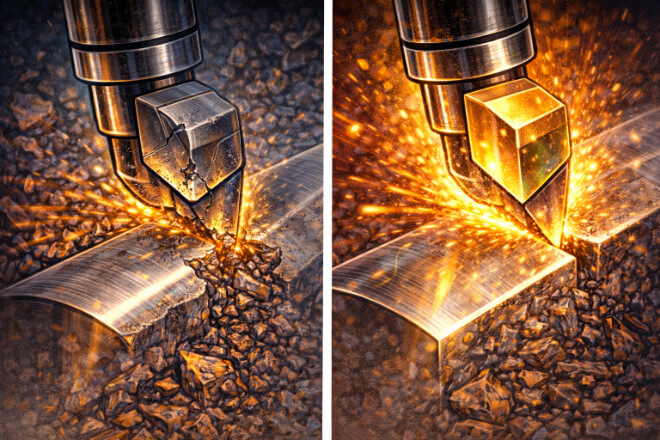

How Coatings Enhance Wear Resistance

One of the key benefits of coatings on tungsten carbide tips is enhanced 耐磨性. In cutting tools, wear is primarily caused by friction and heat generated during operation.

A coating like TiN or TiCN can reduce friction between the tool and the material being cut, thereby reducing the rate at which the tool wears down.

This results in longer tool life and fewer replacements, which can lead to significant cost savings for manufacturers.

The hardness of coatings like TiN also means that the tool’s edge remains sharper for longer, which is critical for maintaining cutting performance over time.

In heavy-duty industries like mining, where tools are subjected to extreme abrasion, coatings provide a vital layer of protection that can extend the tool’s lifespan.

Coatings and Heat Resistance: A Crucial Factor

Heat is one of the most damaging factors for cutting tools. As tools operate at high speeds, the friction generated can cause them to heat up rapidly, leading to tool degradation.

Coatings like TiN and AlTiN are particularly effective in improving the heat resistance of tungsten carbide tips.

These coatings create a barrier that helps the tool withstand higher temperatures without losing its 硬度 or strength.

In applications such as high-speed machining or metal cutting, where temperatures can exceed 1000°C, having a heat-resistant coating ensures that the tungsten carbide tips can maintain their performance without deforming or wearing out prematurely.

The increased heat resistance also reduces the likelihood of thermal shock, which can cause the tool to crack or break.

Corrosion Resistance: Protecting Against Harsh Environments

Tungsten carbide tips are often used in environments that involve exposure to harsh chemicals or moisture. In these situations, corrosion can become a significant problem.

Coatings such as chromium nitride (CrN) provide excellent protection against corrosion, ensuring that the tungsten carbide tips can withstand exposure to acids, salts, and other corrosive substances without deteriorating.

CrN coatings are particularly useful in industries such as 石油和天然气 drilling, where tools are exposed to harsh chemical environments.

By applying a corrosion-resistant coating, manufacturers can ensure that their cutting tools last longer and continue to perform effectively even in challenging conditions.

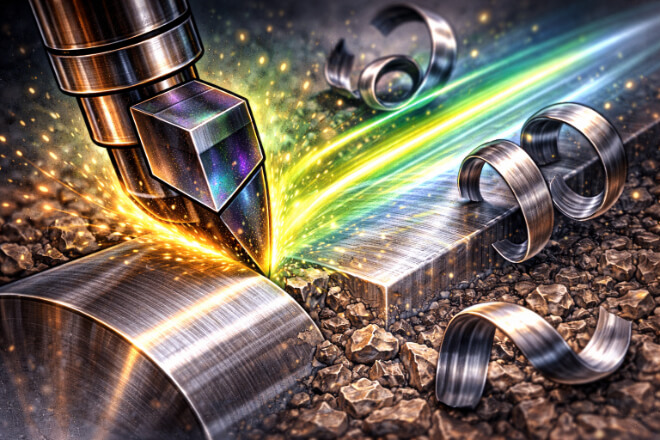

Reduced Friction: Improving Efficiency and Performance

Another major advantage of coatings on tungsten carbide tips is reduced friction. Friction is a key factor that leads to wear and energy loss during machining or cutting operations.

Coatings like diamond-like carbon (DLC) reduce the friction between the cutting tool and the material, leading to smoother operations and better overall performance.

With reduced friction, the tool requires less energy to perform the same tasks, leading to improved efficiency and longer tool life.

This is particularly beneficial in high-volume production environments, where maintaining efficiency and reducing downtime are critical.

Cost-Effectiveness of Coated Tungsten Carbide Tips

While coated tungsten carbide tips are more expensive than uncoated tips, the benefits they offer can make them a more cost-effective option in the long run.

The enhanced 耐磨性, heat resistance, and reduced friction of coated tips mean that tools last longer and require less frequent replacements.

Additionally, coated tungsten carbide tips often perform better in demanding applications, resulting in better quality products and fewer operational disruptions.

This makes them a smart investment for industries that require high-performance tools, such as 航天, 汽车, 和 矿业.

结论

Tungsten carbide tip coatings are an essential technology that significantly enhances the performance and durability of cutting tools.

By improving wear resistance, heat resistance, corrosion resistance, and reducing friction, these coatings ensure that tungsten carbide tips can perform in the most demanding environments.

For industries where tool longevity and performance are critical, investing in coated tungsten carbide tips is a smart choice that provides long-term value.

如果您想了解任何公司的更多详细信息,请随时 联系我们。