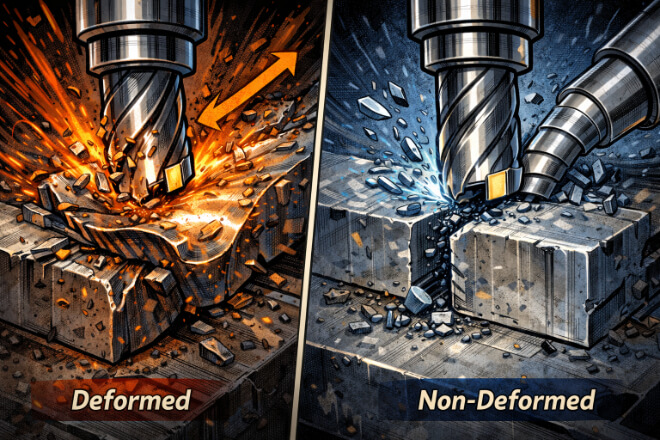

In cutting and machining operations, one of the key challenges is preventing material deformation.

Deformation can lead to poor-quality cuts, additional processing time, and higher costs. Tungsten carbide tips are widely used to combat this issue due to their exceptional 硬度 and precision.

This blog will explore how tungsten carbide tips help prevent material deformation during cutting, leading to improved tool performance, higher product quality, and cost savings.

What Is Material Deformation and Why Is It a Problem?

Material deformation refers to any change in the shape or structure of a material that occurs during cutting or machining.

In cutting operations, deformation can take many forms, including bending, warping, or the formation of burrs. This happens due to excessive force or heat generated during the cutting process.

1). Types of Material Deformation

Plastic Deformation: The material permanently changes shape without returning to its original form.

Elastic Deformation: The material temporarily deforms under stress but returns to its original shape once the stress is removed.

Surface Deformation: Involves the top layer of the material becoming rough, which can impact the final product’s quality.

Material deformation can lead to poor product finishes, increased scrap rates, and the need for additional processing to correct imperfections.

Preventing this deformation is critical to achieving precise cuts, reducing waste, and maintaining high-quality standards.

How Tungsten Carbide Tips Prevent Material Deformation

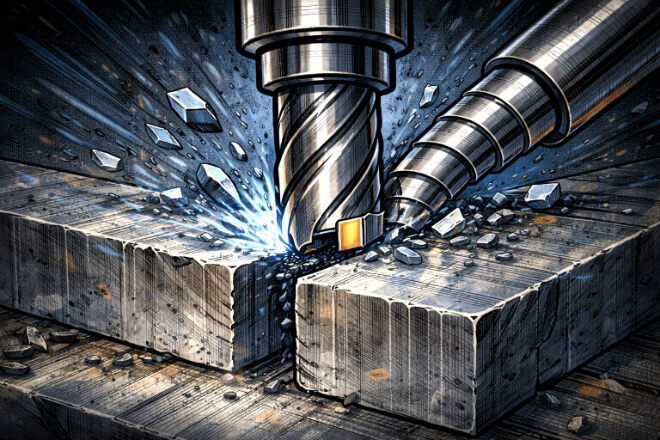

Tungsten carbide tips are an essential tool in preventing material deformation.

Their superior hardness, wear resistance, and cutting precision make them highly effective at minimizing deformation during cutting.

1). 硬度 of Tungsten Carbide Tips

The hardness of tungsten carbide is one of the main reasons it helps prevent deformation. Tungsten carbide tips are extremely hard, second only to diamond.

This hardness allows the tips to maintain sharp edges for longer periods and resist excessive force during cutting operations.

As a result, they exert less pressure on the material, reducing the likelihood of deformation.

2). 耐磨性 for Consistent Performance

Tungsten carbide tips resist wear even in abrasive environments. This means they maintain their cutting effectiveness for longer, ensuring that the cutting edges remain sharp and precise throughout the operation.

Consistent tool performance reduces the chances of applying uneven pressure or force, which could lead to material deformation.

3). Reduced Cutting Forces

Because of their hardness and sharpness, tungsten carbide tips can cut through materials more easily, requiring less cutting force.

Lower cutting forces reduce the risk of material deformation, as the tool interacts with the material in a more controlled, precise manner. This also contributes to smoother cuts and better surface finishes.

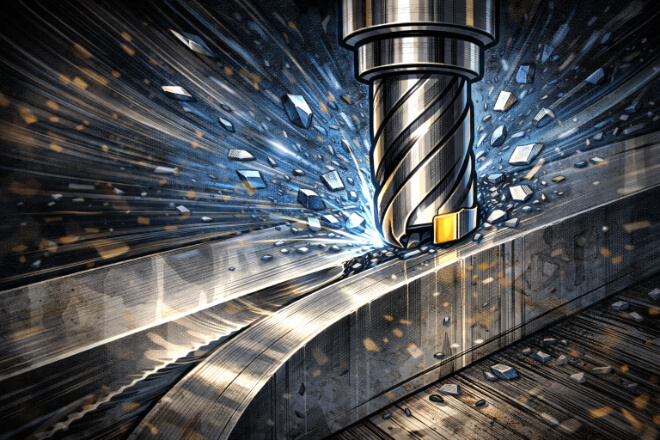

Tungsten Carbide Tips for High Precision in Cutting

Precision is key to preventing material deformation during cutting. Tungsten carbide tips excel in applications that require high precision, such as machining 航天 parts, 汽车 components, and electronics.

1). Maintaining Cutting Edge Geometry

Tungsten carbide tips maintain their cutting edge geometry over time, which is crucial for precise cutting.

As the tool stays sharp and its geometry remains unchanged, the material is cut cleanly and without distortion.

Maintaining the correct geometry prevents the material from being over-stressed during the cutting process, reducing the chances of deformation.

2). Stable Performance at High Cutting Speeds

Tungsten carbide tips are capable of withstanding high cutting speeds without losing their performance.

High-speed cutting generates more heat and increases the risk of tool wear, but tungsten carbide’s ability to resist heat ensures that the tool stays stable, preventing material distortion and ensuring smooth, accurate cuts.

3). Precision in Tough Materials

In industries that deal with tough materials like titanium, steel, and composites, tungsten carbide tips are preferred because they can cut through these materials with precision, minimizing the risk of deformation.

Their ability to maintain sharp edges even in challenging applications makes them ideal for high-precision tasks.

Optimizing Cutting Conditions with Tungsten Carbide Tips

To fully leverage the benefits of tungsten carbide tips in preventing material deformation, it’s essential to optimize the cutting conditions.

This includes adjusting cutting speed, feed rate, and depth of cut to match the material and the application.

1). Cutting Speed

Operating at the right cutting speed is critical. If the speed is too high, excessive heat can cause the material to soften, leading to deformation.

If the speed is too low, the tool may experience more friction, causing premature wear and deformation.

Tungsten carbide tips are designed to handle high cutting speeds, but finding the right speed is key to preventing material deformation.

2). Feed Rate

The feed rate refers to how quickly the material moves under the cutting tool. A higher feed rate can result in higher cutting forces, increasing the risk of deformation.

By optimizing the feed rate, tungsten carbide tips can maintain control over the material, reducing the chances of distortion.

3). Depth of Cut

The depth of cut determines how much material is removed in each pass. Deeper cuts place more stress on the tool and material, increasing the risk of deformation.

Shallow cuts can help maintain control, while still ensuring efficient material removal.

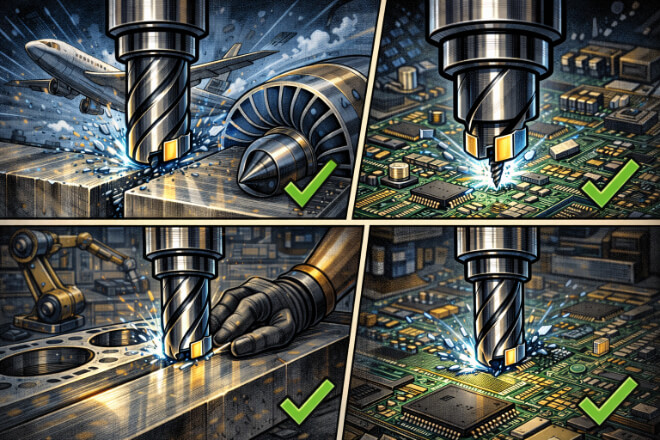

Applications of Tungsten Carbide Tips in Material Deformation Prevention

Tungsten carbide tips are widely used in industries where precision and material integrity are crucial. Here are a few examples of how carbide tips prevent deformation in specific applications:

1). 航天 行业

In aerospace manufacturing, where tight tolerances and high-quality finishes are required, tungsten carbide tips ensure that materials like aluminum, titanium, and steel are cut without deformation, preserving the integrity of the parts.

2). 汽车 行业

Tungsten carbide tips are used for machining engine components, body parts, and gears in the automotive industry.

These tips prevent material distortion, ensuring that the components fit together perfectly and meet safety standards.

3). Electronics Manufacturing

In electronics, precision cutting is vital for components like circuit boards and connectors. Tungsten carbide tips are ideal for preventing material deformation during the cutting and drilling of delicate electronic parts.

结论

Tungsten carbide tips are an essential tool for preventing material deformation during cutting operations.

Their hardness, wear resistance, and ability to maintain sharp cutting edges make them ideal for applications that require precision and accuracy.

By optimizing cutting conditions, using the right carbide tips, and ensuring proper maintenance, businesses can achieve high-quality results, reduce waste, and prolong the life of their tools.

Investing in tungsten carbide tips ensures that material deformation is minimized, improving both the performance and cost-effectiveness of machining operations.

如果您想了解任何公司的更多详细信息,请随时 联系我们。