Decision-makers in industries such as 矿业, 石油和天然气, 航天, 和 precision manufacturing know the challenge of balancing upfront tool cost with long-term performance.

碳化钨球 have become a trusted choice because they combine long lifespan with strong cost-benefit.

While the initial purchase may be higher than steel or ceramic balls, the overall value makes them a smart investment.

This article explores the durability, cost-effectiveness, and return on investment (ROI) of tungsten carbide balls, helping leaders understand when and why they should make the switch.

The Durability Advantage of Tungsten Carbide Balls

The biggest reason for choosing tungsten carbide is its 硬度 and resistance to wear.

With hardness levels approaching that of diamond, tungsten carbide balls can withstand constant contact, high loads, and abrasive environments.

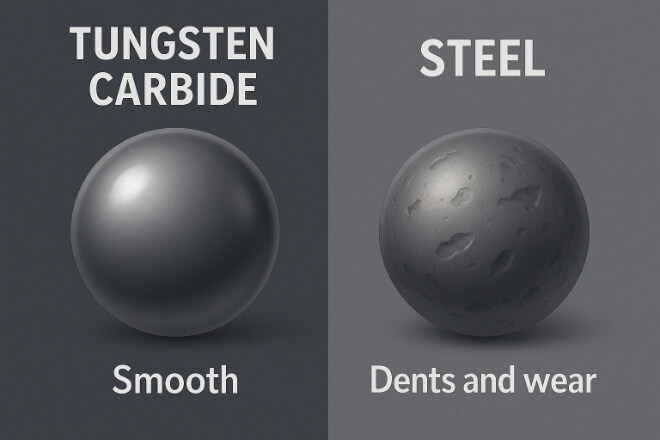

Unlike steel balls, which flatten or deform over time, carbide balls maintain their roundness and surface finish.

This means less friction, smoother movement, and longer equipment performance.

In applications like ball screws, pumps, or precision bearings, the difference can be years of extended service life.

Heat and Corrosion Resistance

Durability goes beyond 硬度. Tungsten carbide balls also perform well in high-temperature or corrosive conditions:

Heat stability: Carbide retains hardness even above 1000°C, unlike steel, which softens.

耐腐蚀: When used in chemical plants or offshore rigs, tungsten carbide is less prone to pitting and rust compared to stainless steel.

This makes them especially valuable in industries where exposure to heat and chemicals is unavoidable.

Cost vs. Lifetime Value

It’s true that tungsten carbide balls cost more upfront. But when you measure cost-per-hour of use instead of purchase price, carbide often delivers better value.

| 材料 | Initial Cost | Lifespan | Cost-Benefit |

|---|---|---|---|

| 钢球 | 低的 | Short (months) | High replacement cost over time |

| 陶瓷球 | 中等的 | 缓和 | Good, but fragile in high shock |

| 碳化钨球 | 高的 | Long (years) | Strong ROI from fewer replacements |

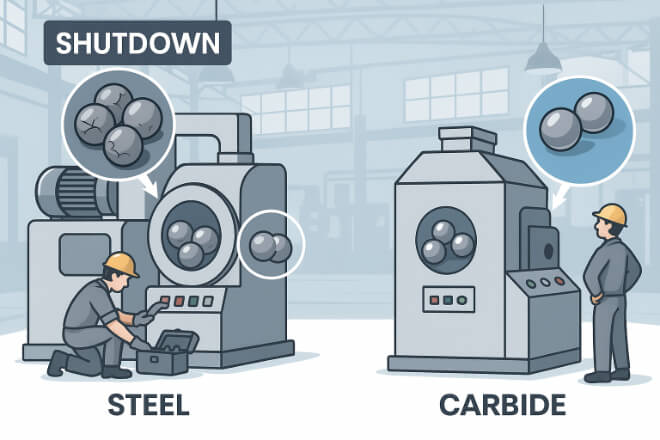

For industries where downtime is costly, the longer lifespan of carbide means less maintenance, fewer shutdowns, and lower operational cost.

Where the ROI Really Shows

Bearings in 矿业 Equipment

Carbide balls last longer in dusty, abrasive environments where steel balls fail quickly.

High-pressure valves with carbide balls resist wear and corrosion, reducing the need for frequent part swaps.

Ball Screws in 航天

Precision movement systems in aircraft rely on carbide balls to ensure safety and accuracy for years.

Pumps in Chemical Plants

The chemical stability of carbide balls means reduced failures, even under harsh fluid conditions.

Comparing Downtime Costs

One often overlooked factor is downtime cost. Replacing failed steel or ceramic balls may seem minor.

But the cost of stopping a production line or drilling rig can be massive. Tungsten carbide balls help reduce unplanned stoppages.

When calculated over the lifecycle, tungsten carbide usually cuts total operational cost by 20–40% compared to steel alternatives.

Decision Guide: When to Choose Tungsten Carbide Balls

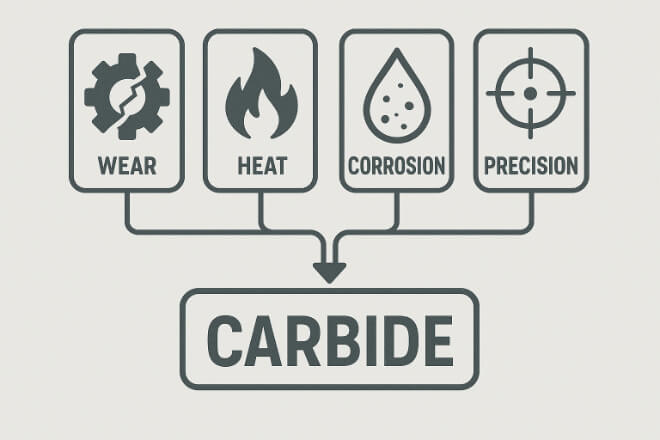

Carbide is the right choice if your application involves:

High wear or abrasive contact

Continuous high load or pressure

Exposure to heat or corrosive fluids

Precision requirements over long cycles

For low-cost, light-duty uses, steel may still make sense. But for industries where failure is expensive, carbide is the material of choice.

最后的想法

Tungsten carbide balls may not be the cheapest upfront option, but they deliver unmatched lifespan and cost-benefit in demanding industries.

By reducing downtime, replacement frequency, and operational costs, they offer decision-makers a reliable way to improve efficiency and profitability.

如果您想了解任何公司的更多详细信息,请随时 联系我们。