在以下行业中 矿业, 石油和天然气, 航天, and heavy machinery, every hour of downtime costs money.

One small component can often be the difference between smooth operations and unexpected shutdowns.

碳化钨球 are one such component, and their long-term value lies in how they reduce downtime, extend equipment life, and lower total operating costs.

This article explains why tungsten carbide balls are the smarter investment, how they deliver long-term value, and what decision-makers should consider when choosing them.

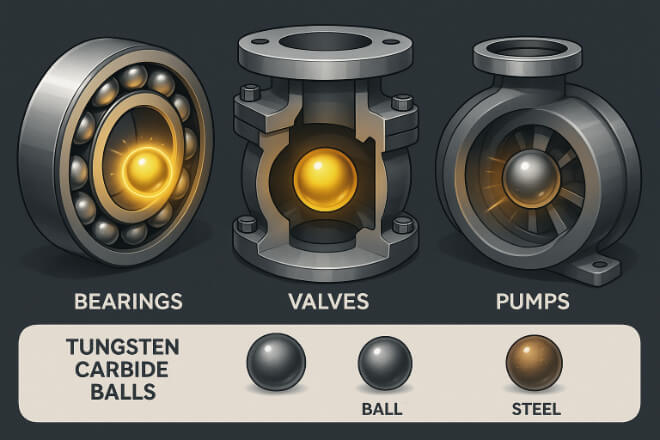

The Role of Tungsten Carbide Balls in Industry

Tungsten carbide balls are widely used in bearings, 阀门, pumps, and ball screws because they handle extreme stress without deforming.

他们的 硬度, 密度, 和 耐磨性 make them ideal for applications where precision and reliability matter.

For industries that operate in abrasive or high-pressure environments, steel balls often fail quickly.

Tungsten carbide, on the other hand, maintains shape, reduces friction, and supports consistent performance even after years of service.

Why Downtime Is So Costly

Unexpected downtime can cost thousands of dollars per hour. A single failed bearing or valve ball can stop an entire production line, drilling operation, or chemical process.

That’s why it’s not enough to look at the purchase price of components—you must consider the true cost of failure.

Using tungsten carbide balls reduces downtime in two ways:

Fewer replacements needed – Longer lifespan means less frequent part swaps.

Consistent performance – Fewer unexpected breakdowns keep systems running smoothly.

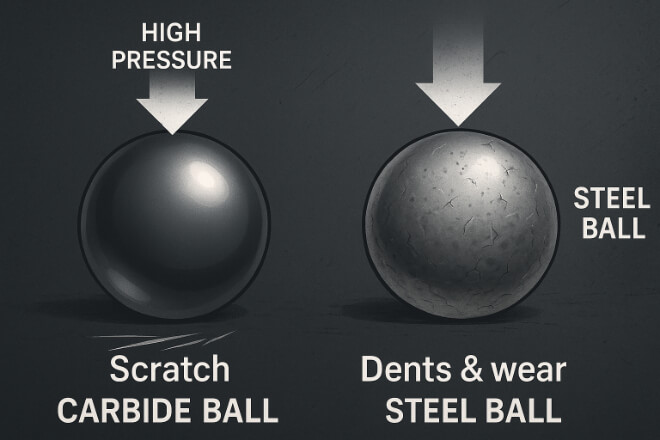

Durability and Wear Resistance

Tungsten carbide is nearly as hard as diamond, and this property directly translates into long life.

Compared to steel or ceramic balls, tungsten carbide resists abrasion, flattening, and deformation.

In high-wear industries like mining, carbide balls in crushers or drilling equipment last up to five times longer than steel.

In aerospace ball screws, carbide ensures accuracy over thousands of cycles. This durability translates into fewer stoppages and lower costs.

Cost-Benefit Comparison

At first glance, carbide balls may look expensive. But their cost-per-hour of operation is often lower than cheaper materials.

| 材料 | Initial Cost | Lifespan | Downtime Risk | Overall Value |

|---|---|---|---|---|

| 钢球 | 低的 | 短的 | 高的 | 低的 |

| 陶瓷球 | 中等的 | 缓和 | 中等的 | 好的 |

| 碳化钨球 | 高的 | 长的 | 低的 | 出色的 |

This comparison shows why carbide is a long-term investment, not just a purchase.

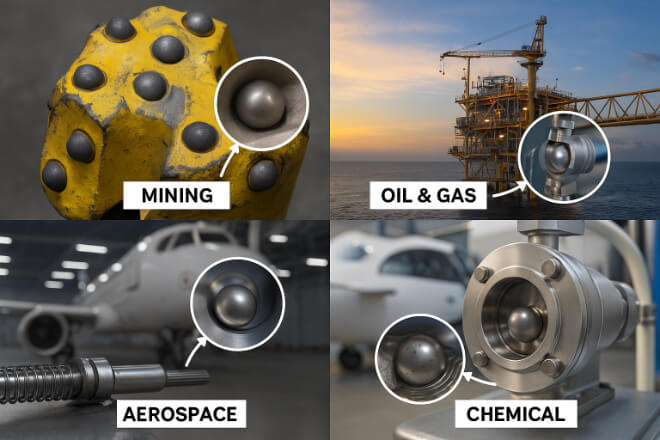

Industries That Benefit the Most

矿业 & Quarrying: Carbide balls in drilling rigs and crushers survive constant abrasion.

石油和天然气: Used in high-pressure valves, they resist both corrosion and extreme force.

航天: Precision ball screws and bearings require carbide to maintain safety standards.

Chemical Processing: Pumps and seals with carbide balls resist aggressive fluids.

These industries prove that the higher upfront cost is outweighed by reduced downtime and maintenance.

Reducing Maintenance Intervals

Maintenance teams know that each shutdown costs both time and labor.

With tungsten carbide balls, inspection and replacement intervals stretch further apart.

This allows teams to focus on other critical tasks rather than constantly replacing worn-out components.

In many cases, switching to carbide reduces maintenance schedules by 30–50%.

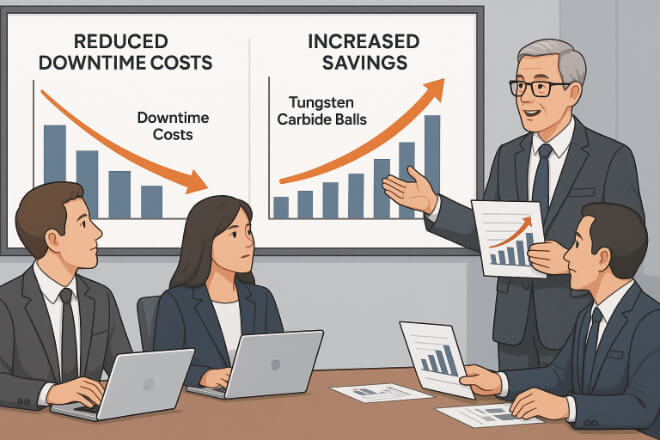

Long-Term ROI for Decision-Makers

For business leaders, the key question is ROI. Tungsten carbide balls provide:

Lower cost per part produced

Reduced unplanned stoppages

Higher equipment reliability

Extended asset lifespan

In the long run, choosing carbide is not about avoiding cost—it’s about avoiding loss.

最后的想法

Downtime is expensive. While steel or ceramic may seem cheaper at purchase, they often cost more in failures, stoppages, and repairs.

Tungsten carbide balls offer the best long-term value by combining durability, wear resistance, and reliability.

For decision-makers, investing in carbide is about more than buying parts—it’s about protecting operations, productivity, and profit.

如果您想了解任何公司的更多详细信息,请随时 联系我们。