Tungsten carbide tips are essential tools in many industries for their durability, precision, and 耐磨性. To ensure they perform at their best, performance testing is crucial.

By testing carbide tips under various conditions, businesses can select the best tools for their specific applications.

This blog explores the importance of performance testing, key factors influencing carbide tip performance, and how it can enhance the longevity and accuracy of tools in various industries.

Why Performance Testing of Tungsten Carbide Tips Is Essential

Performance testing is the process of evaluating how a tool, in this case, tungsten carbide tips, performs under various operating conditions.

It helps determine the tool’s effectiveness, durability, and suitability for specific tasks.

For industries that rely on precision and efficiency, such as 航天, 汽车, 和 石油和天然气, testing the performance of carbide tips ensures that the tools meet the required standards for high-demand applications.

1). Key Benefits of Performance Testing

Ensures Tool Longevity: Performance testing identifies the optimal conditions for using carbide tips, helping businesses maximize their lifespan.

Improves Efficiency: By understanding the limits of carbide tips, manufacturers can optimize cutting speeds, feed rates, and other factors to increase productivity.

Reduces Costs: Testing helps companies avoid costly tool replacements by identifying the best carbide tips for each application.

Enhances Safety: Proper testing ensures that tools perform safely under high stress, reducing the risk of tool failure during operations.

Factors That Affect Tungsten Carbide Tip Performance

The performance of tungsten carbide tips can vary depending on several factors. Testing these tools under different conditions is essential to understanding how they will perform in real-world applications.

1). Material Being Cut

The material being cut plays a significant role in the performance of tungsten carbide tips.

Softer materials like wood or plastic put less stress on the tool, while harder materials like steel or titanium require more durable tools.

Tungsten carbide tips excel at cutting through tough materials, but the performance will vary depending on the material’s 硬度, abrasiveness, and structure.

2). Cutting Speed

The speed at which the tool operates directly impacts its performance. Higher cutting speeds generate more heat, which can affect the tool’s lifespan.

Performance testing helps identify the optimal cutting speeds for different materials and operations, ensuring the carbide tips maintain their sharpness and durability.

3). Tool Geometry

The design and geometry of the carbide tip can also affect its cutting efficiency.

Different geometries, such as the rake angle or chip-breaker design, are tested to find the most effective configurations for specific tasks.

Performance testing can help identify the best geometry for achieving the desired precision and performance.

2.4 Environmental Conditions

Environmental factors such as temperature, humidity, and the presence of abrasives can influence the performance of tungsten carbide tips.

Testing in various environments helps ensure the tips perform consistently across different conditions.

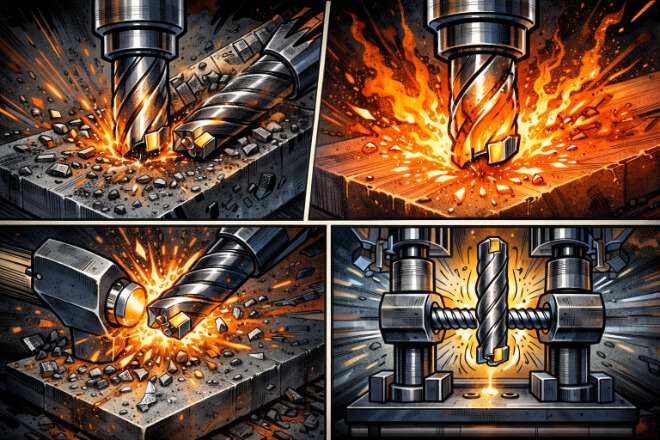

Common Performance Tests for Tungsten Carbide Tips

Several performance tests are conducted to evaluate the effectiveness and durability of tungsten carbide tips.

These tests simulate real-world conditions to determine how the tips will perform in different applications.

1). 耐磨性 Testing

Wear resistance is one of the key performance factors for tungsten carbide tips.

This test involves subjecting the tips to abrasive materials or constant contact with the workpiece to assess how quickly the tool wears down.

The longer the tool resists wear, the more cost-effective it is in the long run.

2). Heat Resistance Testing

Tungsten carbide tips must withstand high temperatures generated during cutting.

Heat resistance testing involves subjecting the tips to various temperatures and evaluating their ability to maintain hardness and performance without deformation.

This test is crucial for applications like high-speed machining or drilling deep wells.

3). Impact Testing

In high-torque or high-pressure environments, carbide tips must endure significant shock and impact without breaking or chipping.

Impact testing involves applying sudden forces to the tips and observing their ability to maintain integrity and performance.

This test is particularly important for industries like mining or oil drilling, where tools often face heavy forces.

4). Fatigue Testing

Fatigue testing involves subjecting the carbide tips to repeated stresses over time, mimicking the continuous use of tools in production environments.

This test helps determine how long a tool will last before it begins to degrade due to repeated use.

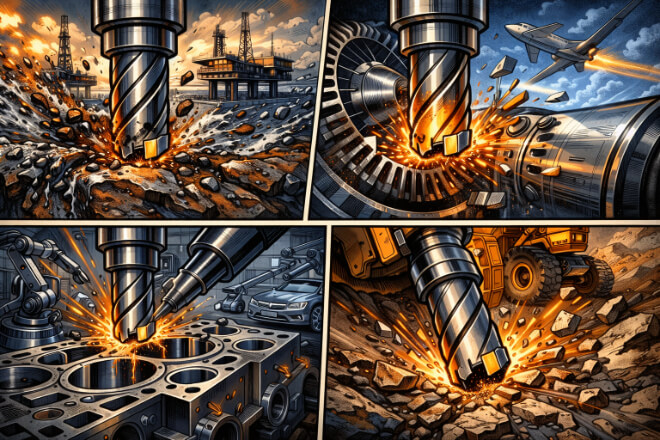

Applications of Tungsten Carbide Tips in Performance Testing

Tungsten carbide tips are tested in a wide range of applications, each requiring specific performance characteristics.

Below are some common industries where performance testing is crucial for selecting the right carbide tips.

1). 石油和天然气 行业

In oil and gas drilling, carbide tips are exposed to high pressures and temperatures. Performance testing ensures that the tips can withstand these extreme conditions without failing.

Drilling tools need to maintain sharpness and durability over long periods, making wear and heat resistance essential factors in performance testing.

In aerospace and automotive manufacturing, precision is key. Tungsten carbide tips are tested to ensure they can cut, drill, and shape metal components with high accuracy.

These industries require tips that can withstand high cutting speeds and maintain a sharp edge for extended periods.

3). 矿业

Mining applications often require tools to endure extreme pressures and abrasiveness.

Tungsten carbide tips are tested for their ability to perform under high-impact conditions, such as in rock drilling or excavation.

Performance testing ensures the carbide tips are tough enough to withstand harsh mining environments.

Evaluating Results from Performance Testing

Once performance tests are complete, businesses need to evaluate the results to determine which tungsten carbide tips are best suited for their needs. Key factors to consider when evaluating results include:

1). Tool Life

Longer tool life means fewer replacements and less downtime. By evaluating the wear and fatigue resistance from testing, businesses can choose carbide tips that provide the best value for their investment.

2). Cutting Precision

Testing results should show how well the carbide tips maintain precision over time. Tools that retain sharpness and accuracy even under high-speed and high-pressure conditions are more desirable.

3). Cost-Effectiveness

While high-performance tungsten carbide tips may come at a higher price, the cost savings from longer tool life and reduced downtime make them a worthwhile investment in the long term. Performance testing helps determine the best value for your needs.

结论

Performance testing of tungsten carbide tips is essential to ensuring that these tools meet the specific demands of various applications.

By conducting wear resistance, heat resistance, impact, and fatigue tests, businesses can make informed decisions about the best carbide tips for their needs.

With the right tips, manufacturers can extend tool life, reduce downtime, and improve productivity, leading to significant cost savings in the long run.

如果您想了解任何公司的更多详细信息,请随时 联系我们。