When it comes to clean, accurate cuts in machining, 碳化钨工具 are often the go-to choice.

They’re harder than high-speed steel, more heat-resistant, and offer better performance in high-speed applications. But just having a carbide tool isn’t enough—you also need to use it the right way.

In this guide, we’ll walk you through the best practices and smart tips to get the most out of your tungsten carbide cutting tools.

Whether you’re running a CNC machine shop or handling manual cutting jobs, these tips will help you extend tool life, reduce mistakes, and achieve better results.

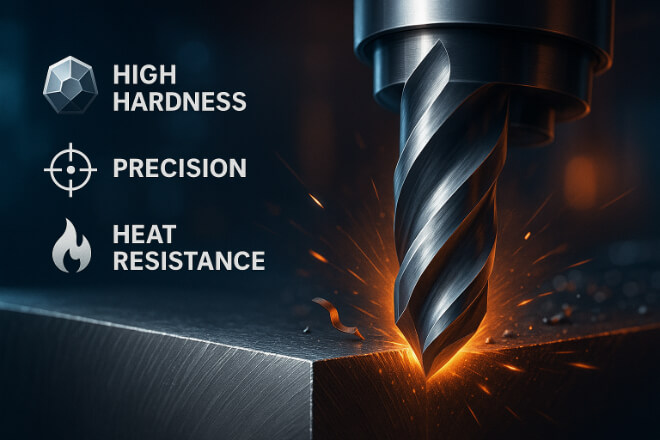

1. Why Tungsten Carbide is Ideal for Precision Cutting

Tungsten carbide is known for its exceptional hardness—almost as hard as diamond.

This means it keeps a sharp edge much longer than other materials. It can also handle high cutting speeds and heat without losing its shape or sharpness.

Because of this, carbide tools are ideal for:

Tight-tolerance machining

High-speed CNC operations

Cutting hard or abrasive materials

Producing clean surface finishes

If your goal is consistent accuracy and longer tool life, tungsten carbide is hard to beat.

2. Choose the Right Tool for the Job

Precision starts with tool selection. Not all carbide tools are made equal. You need to consider:

Tool geometry – Choose the right shape and edge type for your material and operation.

Coating – Coated tools reduce wear, heat, and friction. Common coatings like TiAlN or DLC enhance performance.

Grade – Different carbide grades have different grain sizes and binder content. Finer grains are better for precision.

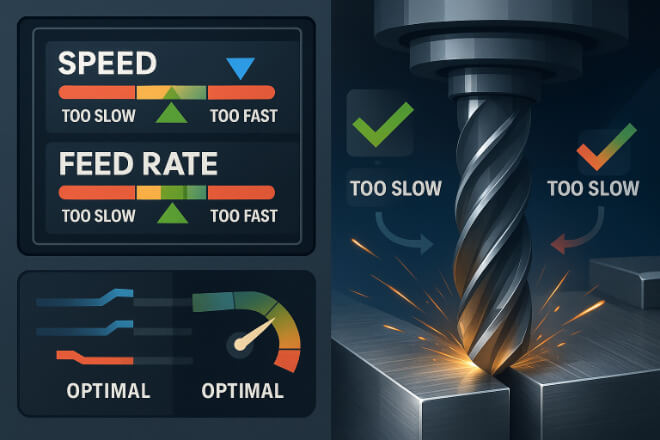

3. Set Proper Speeds and Feeds

Using the wrong speed or feed rate can ruin even the best carbide tool. For precision cutting:

Too fast = excessive heat and early tool wear

Too slow = rubbing, poor surface finish

Follow manufacturer recommendations and adjust based on:

Workpiece material

Tool diameter

Desired finish

A good starting point: higher speeds and lower feeds typically give better surface finishes, especially with carbide tools.

4. Keep Your Tools Sharp

Even the hardest carbide tool gets dull over time. Using a dull tool leads to:

Poor accuracy

Increased vibration

More heat and wear

To maintain precision:

Inspect tools regularly for wear or chipping

Use regrinding services to restore edge sharpness

Store tools in protective cases to avoid damage

A sharp tool not only cuts better—it also protects your machine and reduces scrap.

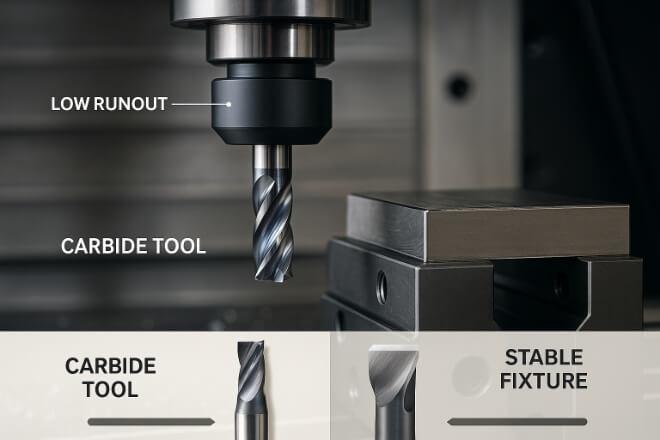

5. Use Proper Tool Holders and Fixturing

Precision machining isn’t just about the tool—it’s also about how it’s held.

Poor tool holding causes:

Runout (tool wobble)

Chatter

Inconsistent cuts

Best practices:

Use high-quality tool holders with minimal runout

Balance your tools if operating at high RPMs

Make sure workpieces are firmly clamped with no movement

Solid fixturing equals solid results.

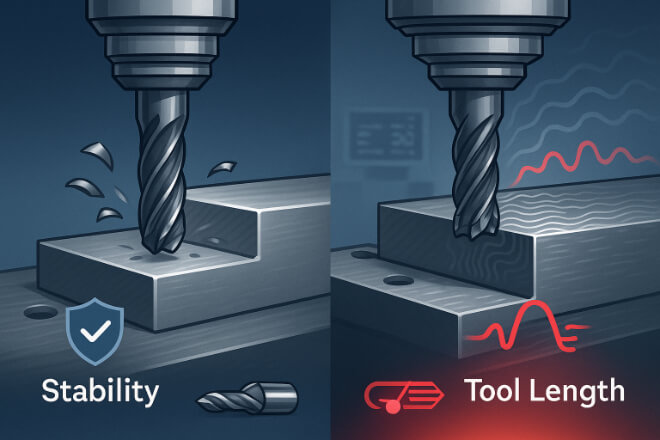

6. Minimize Vibration and Chatter

Vibration (or chatter) is the enemy of clean cuts. It affects surface finish, tool life, and precision.

To reduce chatter:

Use shorter tool overhangs

Optimize cutting parameters (slightly increase speed or reduce depth)

Make sure your machine and spindle are in good condition

If vibration continues, switch to a tool with a different flute design or cutting angle.

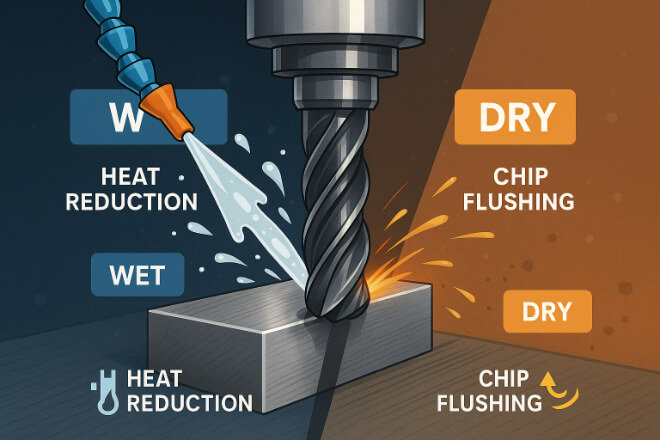

7. Apply Coolant Wisely

Coolant helps reduce heat and flush chips, but using too much or the wrong type can cause problems.

Tips:

Use mist or flood coolant for metal materials

Dry machining can work well with coated carbide tools (especially on aluminum)

Keep coolant nozzles aimed directly at the cutting edge

Less heat means longer tool life and better part finishes.

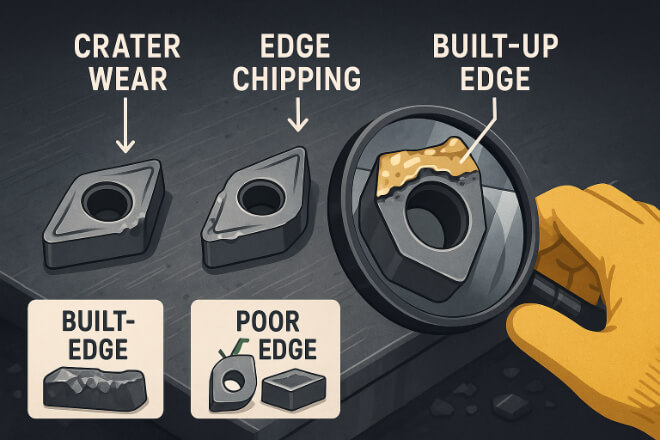

8. Watch for Wear Patterns

Reading your tool’s wear pattern helps you catch problems early. Common wear types include:

Crater wear – from excessive speed or poor chip flow

Edge chipping – from vibration or poor fixturing

Built-up edge – from soft, sticky materials like aluminum

If you spot early signs of wear, adjust your cutting parameters or tool selection before things get worse.

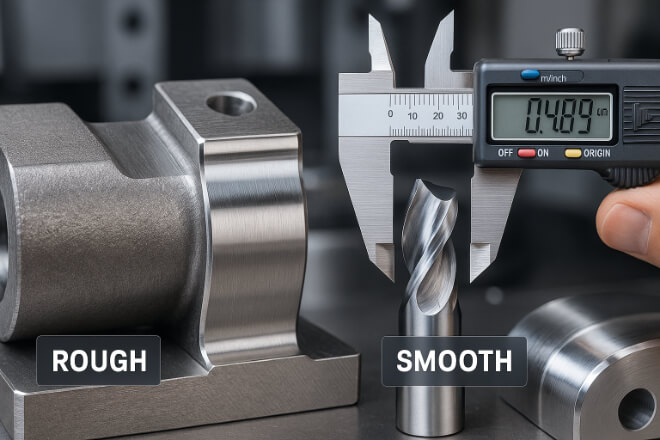

9. Don’t Ignore Surface Finish

Precision isn’t just about measurements—it’s also about how the final part looks and feels.

To get a better finish:

Use a finishing pass at higher speeds and lower feeds

Use tools with polished flutes for aluminum or plastics

Keep your machine clean to avoid recutting chips

Clean finishes mean less post-processing and happier customers.

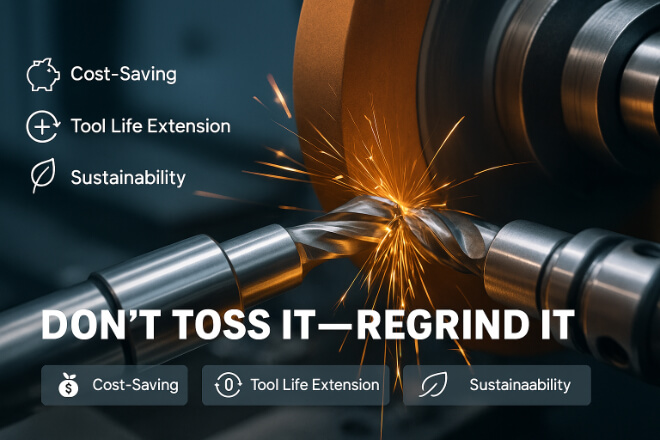

10. Regrind Instead of Replace

Tungsten carbide tools aren’t cheap—but they are reusable. Many tools can be reground several times.

Instead of replacing worn tools:

Send them to a regrinding service

Recoat the tool if needed

This saves money and reduces waste without sacrificing performance.

最后的想法

Precision machining isn’t just about expensive machines or software—it starts with the cutting tool.

Tungsten carbide tools give you the edge (literally) to achieve tight tolerances, clean finishes, and consistent performance.

But they work best when used properly.

By choosing the right tool, setting the correct parameters, and maintaining your equipment, you’ll not only improve quality—you’ll save time and money too.

如果您想了解任何公司的更多详细信息,请随时 联系我们.