硬质合金耐磨部件 are widely used in industries like 矿业, 石油和天然气, 金属成型, 木工, and more.

They are chosen because of their 硬度, 耐磨性, and long service life. However, even the best carbide components can fail if they are not designed, handled, or maintained correctly.

For decision-makers, understanding how failures happen—and how to prevent them—is key to keeping machines running smoothly and avoiding costly downtime.

This article explores the common causes of failures in carbide wear components and provides practical strategies to extend their life.

Why Carbide Wear Components Fail

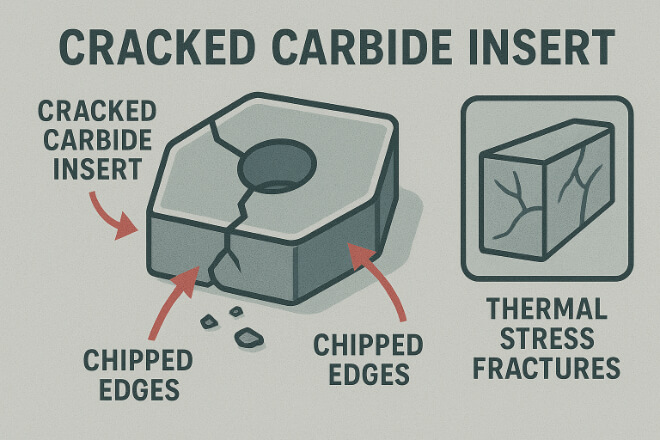

Carbide is strong, but it is not indestructible. Failures usually occur because of:

Excessive stress or impact that exceeds design limits.

Improper grades or binder choices for the application.

Corrosion or chemical attack in harsh environments.

Thermal cracking from extreme temperature changes.

Poor maintenance leading to unexpected wear.

Each of these factors can lead to fractures, chipping, or rapid wear, reducing the value of carbide components.

The Role of Material Selection

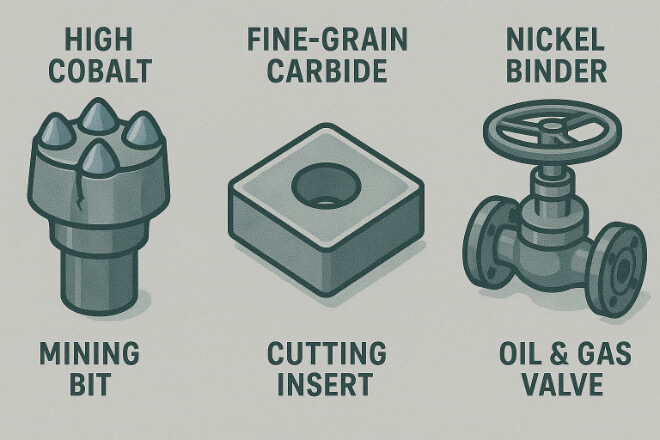

Choosing the right carbide grade is the first step to preventing failures. Not all grades are the same. For example:

High-cobalt binders give more 韧性 for impact-heavy uses like mining tools.

Low-binder, fine-grain carbides offer maximum 硬度 for cutting tools.

Corrosion-resistant binders like nickel are better for oil & gas.

If the wrong grade is selected, even the most advanced carbide will not last. Working with reliable suppliers who provide material expertise is essential.

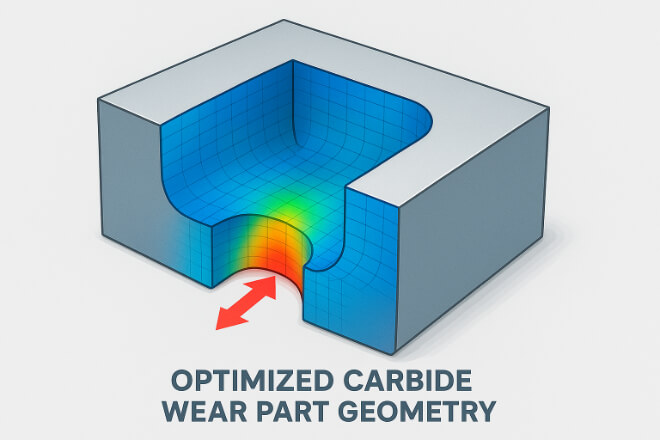

Proper Design and Engineering

Many failures come from design errors, such as sharp corners that create stress points or parts that are too thin for heavy loads. Engineers must consider:

Load distribution: spreading stress evenly.

Geometry optimization: avoiding weak points.

Surface finishing: reducing micro-cracks that can grow into major failures.

Advanced simulation tools now allow manufacturers to predict how a part will perform before it’s produced, reducing the risk of early failures.

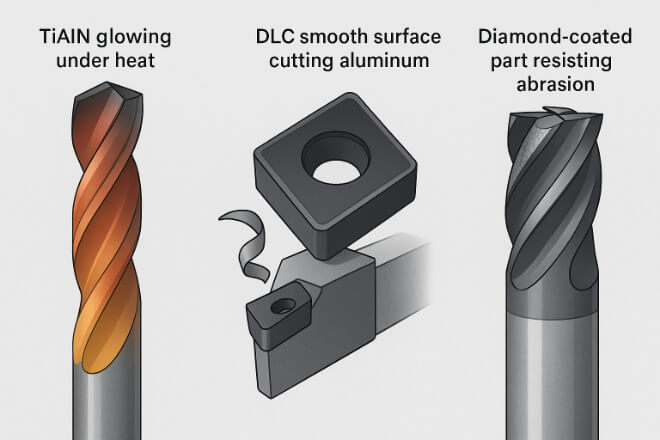

Impact of Coatings

Protective coatings like TiAlN, DLC, or CVD diamond can significantly improve performance by reducing friction, heat, and chemical wear.

However, coatings must be applied properly and matched to the application. For example:

TiAlN is ideal for high-heat machining.

DLC coatings reduce sticking in aluminum processing.

Diamond coatings provide the longest life in abrasive conditions.

Using the wrong coating—or skipping coatings—can shorten component life.

Maintenance Practices to Prevent Failures

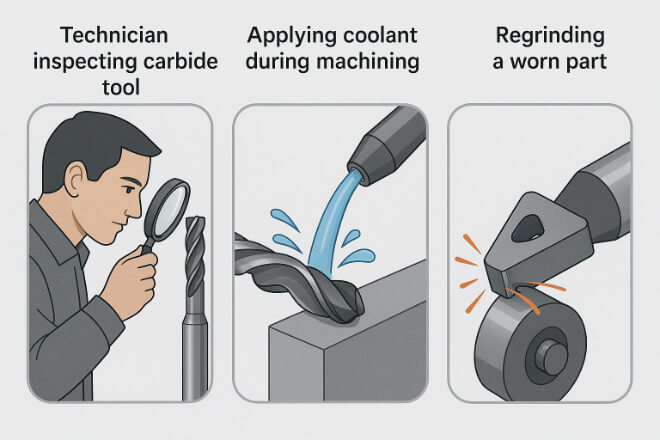

Even the best-designed carbide parts can fail without proper care. Maintenance practices that help include:

Regular inspections for cracks, chipping, or abnormal wear.

Lubrication and coolant use to control heat and friction.

Proper cleaning to avoid chemical damage.

Timely regrinding or reconditioning instead of waiting for total failure.

A proactive approach to maintenance can extend tool life and reduce costs.

Training and Handling

Carbide wear parts are tough but also brittle under impact. Mishandling them during installation or transport can cause micro-cracks that later lead to big failures. Workers should be trained to:

Handle carbide parts carefully.

Store them in dry, controlled environments.

Use proper installation tools.

Preventing failures often starts with the way components are treated before they even touch the machine.

Supplier Quality and Standards

Not all carbide suppliers follow strict standards. Subpar parts made with recycled powder, poor binder quality, or weak inspections are more likely to fail. Decision-makers should always:

Ask for ISO or ASTM certifications.

Check if suppliers offer traceability and batch control.

Choosing a trusted supplier can make the difference between success and costly failures.

The Cost of Ignoring Failures

When carbide parts fail, the costs go beyond just replacing the component. Failures can lead to:

Production downtime.

Scrap and rework costs.

Machine damage.

Customer delivery delays.

Preventing failures is not just about part performance—it is a strategic decision that impacts the entire business.

结论

Carbide wear components are critical for industries where performance and durability are non-negotiable.

By focusing on material selection, design, coatings, maintenance, handling, and supplier quality, companies can prevent failures and maximize the return on their carbide investments.

For decision-makers, the key takeaway is simple: prevention is cheaper than failure.

如果您想了解任何公司的更多详细信息,请随时 联系我们。