Tungsten carbide bushings are used in pumps, compressors, mixers, and many rotating systems because they resist wear and last long under heavy load.

But when a bushing begins to fail, the wear pattern on its surface tells a story. By reading these patterns, engineers can identify the real cause of failure and prevent the same problem from happening again.

This article explains the most common wear patterns on tungsten carbide bushings and what each one tells you about the machine’s operating condition.

Why Wear Patterns Matter in Tungsten Carbide Bushings

Wear marks are more than surface damage—they are signs of deeper mechanical issues.

WC bushings are extremely hard, so they do not wear easily. When they do, something in the system is wrong.

Wear Patterns Provide Clues About:

Loading conditions

Shaft alignment

Lubrication quality

Clearance problems

Vibration or instability

Process fluid contamination

Understanding wear patterns helps maintenance teams make the correct repair and avoid unnecessary downtime.

Types of Wear Patterns and What They Indicate

Tungsten carbide bushings show different wear features depending on the root cause. Below are the most common patterns.

| Wear Pattern | 主要原因 | What It Means |

|---|---|---|

| One-sided wear | Misalignment | Shaft centerline is not aligned with housing |

| Uniform circumferential wear | Tight clearance | Continuous contact due to insufficient gap |

| Random patch wear | Loose clearance | Shaft movement causing instability |

| Scoring / scratches | Contamination | Hard particles between shaft and bushing |

| Burn marks | 过热 | Poor lubrication or tight fit |

| Chipping at edges | Shock or thermal stress | Brittle failure due to loading or rapid temperature change |

One-Sided Wear: A Clear Sign of Misalignment

Misalignment is one of the most common causes of WC bushing failure. It happens when the shaft is not centered inside the bushing.

1). How to Identify It

One side of the bore is polished or worn

Wear depth decreases gradually across the diameter

Elliptical or oval wear shape

Possible diagonal polish marks

2). What Misalignment Means

Poor installation

Shaft bending

Housing distortion

Worn bearings affecting shaft centerline

Correcting alignment often stops the wear pattern from repeating.

Circular or Full-Contact Wear: Clearance Too Tight

When clearance between the shaft and bushing is too small, the shaft makes full 360° contact. WC bushings are extremely hard, so heat rises quickly in this condition.

1). How to Identify It

Smooth, even wear around the entire bore

Light polish ring or heavy scoring depending on severity

Heat tinting (blue or brown discoloration)

2). What Tight Clearance Means

Incorrect machining tolerance

Thermal expansion reducing the running gap

Material swelling due to fluid absorption

Shaft oversize due to plating or repair

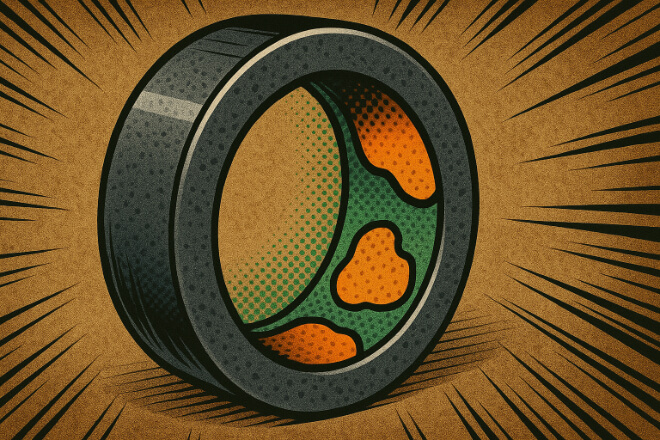

Patch Wear: Clearance Too Loose

Loose clearance allows the shaft to move unpredictably. Instead of even contact, the shaft touches the bushing at random points.

1). How to Identify It

Wear appears in scattered patches

No continuous full-contact pattern

Vibration marks may also appear

2). What Loose Clearance Means

Shaft wear reducing diameter

Housing distortion increasing clearance

Incorrect reassembly

Operating conditions causing shaft instability

Loose clearance often leads to vibration, noise, and early failure.

Scoring and Scratches: Contamination in the System

Even a tiny particle of sand, metal, or ceramic can score tungsten carbide. These foreign objects usually enter through the process fluid or poor cleaning.

1). How to Identify It

Long, straight scratches along the shaft direction

Deep grooves if large particles are present

Multiple directional scratches if particles circulate

2). What Contamination Means

Poor filtration

Seal leakage

Abrasive slurry in the system

Shaft surface dragging particles across the bushing

Removing debris and improving filtration usually solves the issue.

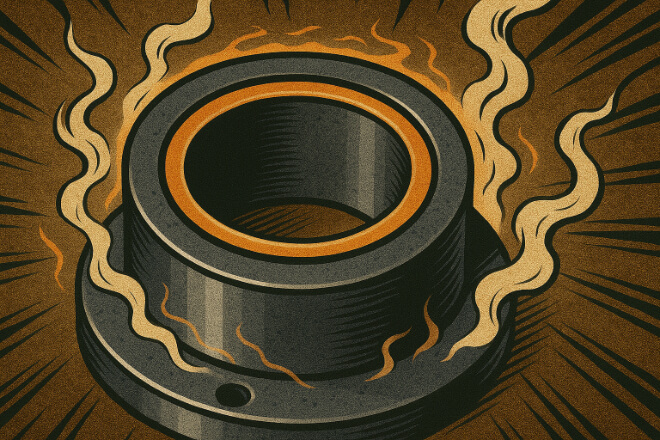

Burn Marks or Heat Damage: Lubrication or Friction Problem

WC bushings tolerate high temperatures, but poor lubrication or tight fits generate more heat than the material can handle.

1). How to Identify It

Blue, brown, or black heat marks

Micro-cracks due to thermal shock

Surface glazing

2). What Heat Damage Means

Boundary lubrication or dry running

Sudden losses in fluid flow

Incorrect material pairing

Tight clearance increasing friction

This wear type often appears suddenly rather than gradually.

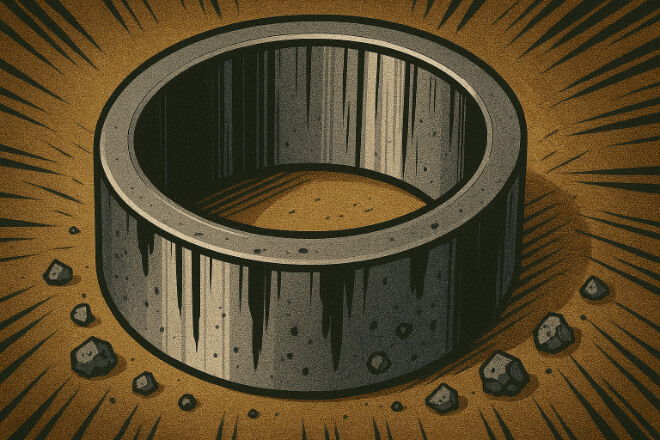

Edge Chipping: Stress or Shock Load Failure

Tungsten carbide is hard but brittle. When loads concentrate at the edge—often due to misalignment, vibration, or poor installation—chipping occurs.

1). How to Identify It

Small chips at both entry and exit edges

Breakouts around the bore

Angular fracture lines

2). What Edge Chipping Means

Impact loading during startup

Shaft vibration in operation

Thermal shock

Incorrect press-fit installation

Chipping is a warning sign that failure may soon follow.

Comparing Wear Patterns for Easier Diagnosis

| Wear Pattern | Primary Cause | Recommended Action |

|---|---|---|

| One-sided wear | Misalignment | Check shaft and housing alignment |

| Uniform wear | Tight clearance | Increase clearance or reduce heat |

| Random patches | Loose clearance | Restore correct gap |

| Scoring | Contamination | Improve filtration and clean components |

| Burn marks | 过热 | Improve lubrication and ventilation |

| Edge chipping | Shock load / vibration | Stabilize shaft and review press-fit method |

结论

Wear patterns on tungsten carbide bushings are valuable indicators of what is happening inside your equipment.

By learning to read these marks, maintenance teams can pinpoint the real problem—whether misalignment, clearance issues, contamination, overheating, or shock loading—and take the correct action.

A small visual clue can prevent a major failure and save significant downtime.

如果您想了解任何公司的更多详细信息,请随时 联系我们。