碳化钨切削刀具 are known for their strength, durability, and ability to cut even the toughest materials.

But how are these tools made? Many people use carbide tools daily in machining, but few understand the complex and fascinating process behind their creation.

In this article, we’ll break down the complete manufacturing process of tungsten carbide cutting tools — from powder to finished product — using simple words and clear steps.

Whether you’re a plant manager, procurement leader, or engineer, knowing how these tools are made helps you choose the right supplier and ensure consistent quality.

1. Raw Materials: Tungsten and Cobalt

The process starts with raw materials — mainly tungsten and cobalt. Tungsten comes from tungsten ore, which is processed into tungsten oxide.

This oxide is reduced to metallic tungsten powder using hydrogen. Cobalt, often used as a binder, is added to make the material tougher.

The powders must be extremely fine — usually under 5 microns. The smaller the particles, the better the final tool’s strength and 耐磨性。

2. Powder Mixing and Blending

Once the tungsten and cobalt powders are ready, they are mixed together with other elements if needed.

For example, titanium carbide or tantalum carbide might be added to improve heat resistance or 韧性。

A process called wet milling is used to mix the powders evenly. A liquid (like ethanol or water) is added, and the mix is blended in a ball mill with tiny metal balls that help break down particles and create a smooth, consistent mixture.

This slurry (wet mix) is then dried to remove the liquid. What’s left is a soft, uniform powder ready for shaping.

3. Pressing the Powder into Shape

The dry powder is pressed into shape using a machine called a compaction press.

This step turns the powder into a “green compact” — a part that looks like a cutting tool but is still fragile and soft.

Two common pressing methods are used:

Uniaxial pressing for simple shapes like blanks or discs

Cold Isostatic Pressing (CIP) for more complex or larger shapes

These parts are typically pressed at 150–300 MPa of pressure to hold their form.

4. Pre-Sintering (Optional Step)

In some cases, the green parts go through pre-sintering. This is a low-temperature heating step (around 700–900°C) that removes any remaining moisture and helps harden the shape slightly.

It makes the part easier to handle during grinding or machining before final sintering.

This step also improves dimensional stability and reduces the risk of defects later.

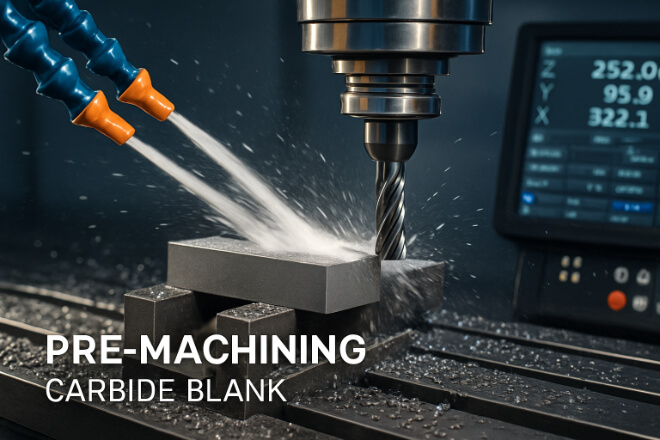

5. CNC Pre-Machining and Shaping

After pressing and possibly pre-sintering, the parts may be machined or ground slightly to get closer to their final shape. At this stage, the material is still relatively soft and easier to work with.

This step helps:

Add holes or slots

Prepare the part for tight-tolerance grinding later

Remove surface defects from pressing

It also helps reduce material waste in the next stages.

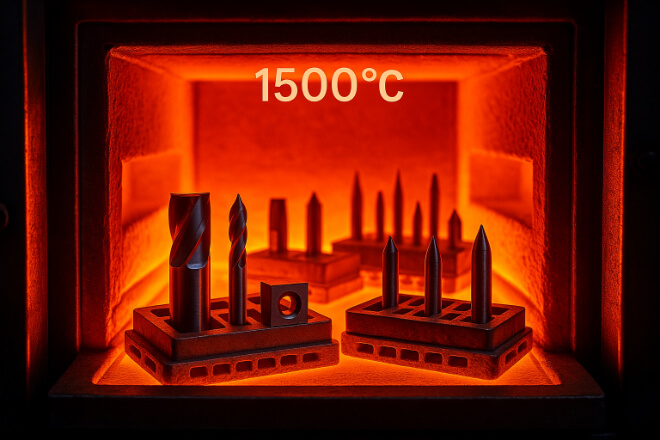

6. Sintering: Turning Powder into Solid Carbide

Sintering is the most important part of the process. It transforms the pressed powder into a solid, hard, and dense material by heating it in a special furnace.

Here’s what happens:

The part is heated to around 1400–1500°C

The cobalt melts and binds the tungsten grains together

The part shrinks by about 20% in size but becomes much harder and denser

This process takes several hours and must be carefully controlled to avoid cracks or internal stress.

Once sintered, the tool is now fully solid tungsten carbide — incredibly hard but also brittle, which is why precision grinding is needed next.

7. Grinding to Final Dimensions

After sintering, the part is extremely hard and cannot be machined with regular tools. Instead, diamond grinding wheels are used to shape the final dimensions and cutting edges.

This is where tight tolerances (such as ±0.001mm) are achieved. Grinding is done on specialized CNC grinders and includes steps like:

OD (outer diameter) grinding

Centerless grinding

Fluting or edge profiling

End cutting face formation

Good grinding quality is critical — poor grinding can cause micro-cracks or uneven cutting edges that reduce tool life.

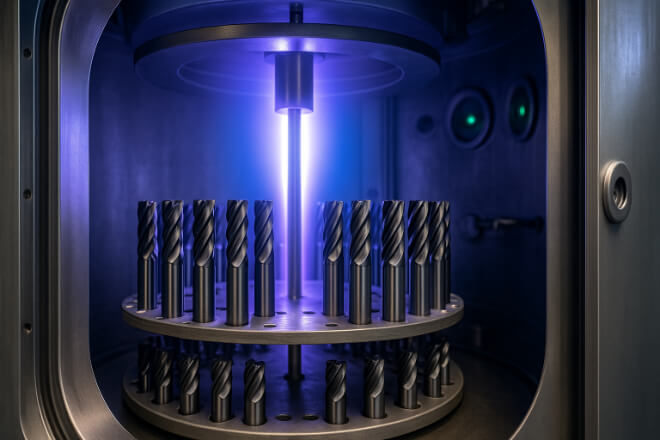

8. Applying Tool Coatings (Optional but Important)

Many modern tungsten carbide cutting tools include high-performance coatings to increase tool life and improve performance.

Some common coatings include:

TiAlN (Titanium Aluminum Nitride): Great for high-speed machining

AlTiN: Similar but better at handling heat

DLC (Diamond-Like Carbon): Perfect for aluminum or plastic

CVD Diamond Coatings: For ultra-hard machining tasks like graphite or composites

Coatings are applied using PVD (Physical Vapor Deposition) or CVD (Chemical Vapor Deposition) systems in clean, high-tech chambers.

These coatings:

Reduce wear and friction

Prevent material buildup

Allow faster cutting speeds

Extend tool life by 2–5x in many cases

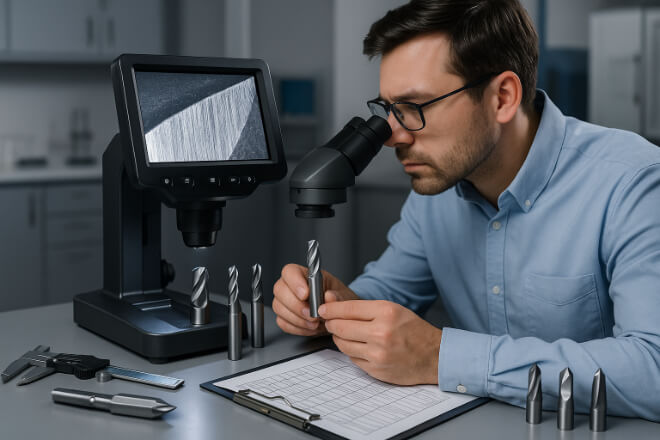

9. Quality Inspection and Testing

Before the tools are shipped, they go through strict quality checks. These checks make sure that each tool meets required tolerances, performance, and safety standards.

Inspections include:

Visual inspection for cracks, chips, or coating defects

Microscopic check of cutting edges

Dimensional measurement using precision tools

硬度 testing

Runout and balance testing for rotary tools

Reliable suppliers usually provide inspection reports or certificates, especially for critical applications in aerospace or 汽车 industries.

10. Laser Marking and Packaging

Finally, finished tools are marked using a laser engraving system. This adds part numbers, sizes, or customer codes without damaging the surface.

After marking, the tools are carefully cleaned, oiled (if needed), and packed for shipment. Tools may be packed in:

Plastic single-use boxes

Foam-lined trays

Bulk cartons with separators

Proper packaging ensures that edges are protected during transport and storage.

Summary Table: Tungsten Carbide Cutting Tool Production Steps

| Step | 描述 |

|---|---|

| 1. Raw Material Prep | Blend tungsten and cobalt powders |

| 2. Powder Mixing | Wet milling with additives |

| 3. Pressing | Form powder into green compact |

| 4. Pre-Sintering | Optional low-heat stabilization |

| 5. CNC Pre-Machining | Rough shaping for features |

| 6. Sintering | High-temperature solidification |

| 7. Final Grinding | Achieve precision shape and edge |

| 8. Coating | Apply wear-resistant layer |

| 9. Quality Inspection | Test geometry and hardness |

| 10. Marking & Packaging | Laser label and safely pack tools |

最后的想法

Tungsten carbide cutting tools may seem like simple components, but their manufacturing process is anything but simple.

Every step — from powder blending to CNC grinding — must be done with care, precision, and deep technical knowledge.

For companies looking to reduce downtime, improve machining quality, and get more value from every tool, understanding this process helps you make better sourcing decisions.

Choose a supplier that controls every stage of production, offers consistent quality, and stands behind their products. That’s how you get tools that truly perform.

Ready to find a supplier you can trust? Visit 雷托普兹 to explore tungsten carbide cutting tools designed for performance and built to last.