Sustainability is no longer just a trend—it is a requirement for industries like 石油和天然气, marine, power generation, and chemical processing.

Every component in a system now plays a role in improving efficiency, reducing waste, and lowering environmental impact.

Seal rings are small parts but have a big effect. When they fail, companies face downtime, leaks, and safety risks.

Among many options, 碳化钨密封环 stand out because they not only provide strength and durability but also support sustainable sealing solutions.

This article explains how they contribute to sustainability and why they are the smart choice for decision-makers.

What Makes Sealing Solutions Sustainable?

A sustainable sealing solution is one that:

Lasts longer, reducing waste and resource use.

Improves energy efficiency by minimizing leaks and friction.

Supports recycling to reduce material demand.

Protects the environment by preventing harmful fluid leakage.

Sustainability in sealing means reducing both the operational cost and the environmental footprint.

碳化钨密封环的性能

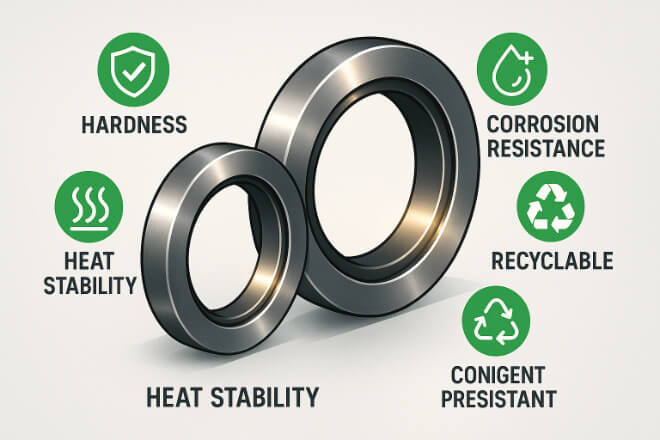

Tungsten carbide is a compound of tungsten and carbon, often bonded with cobalt or nickel. It offers unique properties that support sustainable use:

极端 硬度 – Resists wear, extending service life.

High Compressive Strength – Performs reliably under heavy loads.

Thermal Stability – Maintains strength in high temperatures.

耐腐蚀 – Resists chemicals, seawater, and oil.

Recyclability – Can be collected and reused after end of life.

These features make tungsten carbide a material that reduces waste and ensures efficiency.

Reducing Waste Through Long Service Life

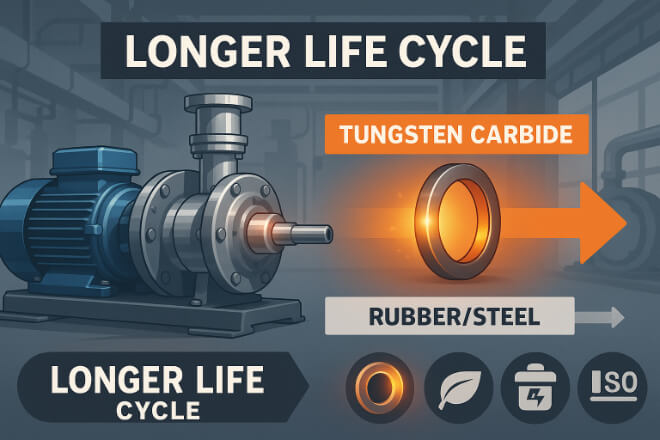

One of the biggest sustainability advantages is the long service life of tungsten carbide seal rings.

Unlike rubber or steel seals that wear out quickly, tungsten carbide lasts for years in harsh conditions. This means:

更少的替换

Lower material waste

Less equipment downtime

For companies, this reduces the environmental and financial costs of frequent replacements.

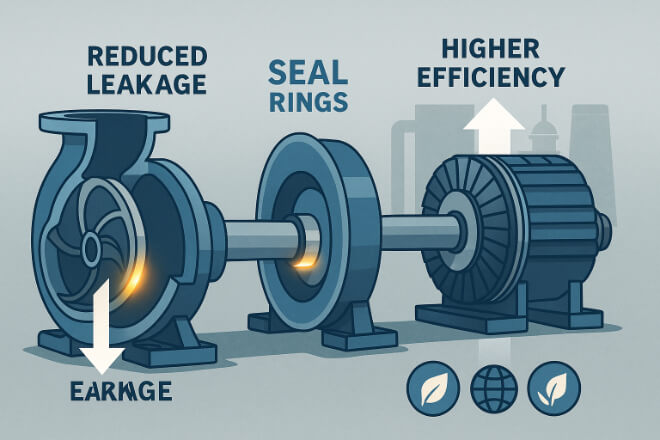

Energy Efficiency in Sealing Systems

Seal failure often leads to leaks, friction, or energy loss. Tungsten carbide seal rings maintain tight sealing even under high pressure and heat, improving efficiency.

In pumps → Less energy wasted on overcoming leakage.

In turbines → Better sealing means improved performance.

In marine systems → Reduced water ingress prevents energy loss.

Better energy efficiency supports both sustainability goals and cost savings.

Recycling and Circular Economy Benefits

Unlike many sealing materials, tungsten carbide can be recycled. Worn seal rings are collected, broken down, and processed into new products. This:

Reduces demand for raw tungsten mining

Cuts carbon emissions from new material production

Supports circular economy practices

For industries under pressure to reduce environmental impact, recycling programs for tungsten carbide are a strong sustainability advantage.

Preventing Environmental Hazards

Leaks from failed seals can lead to environmental pollution, regulatory penalties, and reputational damage.

Tungsten carbide seal rings reduce this risk by maintaining reliable sealing under extreme conditions.

For industries handling oil, chemicals, or wastewater, this not only protects the environment but also ensures compliance with sustainability standards.

与其他密封材料的比较

Rubber Seals → Low cost but wear quickly, not sustainable long-term.

Steel Seals → Strong but corrode, requiring frequent replacement.

Ceramic Seals → Resistant to corrosion but brittle under shock.

Tungsten Carbide Seals → Best combination of durability, efficiency, and recyclability.

This makes tungsten carbide the leading option for companies balancing performance and sustainability.

Industry Examples of Sustainable Applications

Power Generation – Longer-lasting seals in turbines reduce material use.

Marine Industry – Corrosion-resistant rings reduce failures in seawater pumps.

石油和天然气 – Reliable seals prevent harmful leaks, protecting the environment.

Chemical Plants – Durable rings reduce waste in aggressive chemical conditions.

Across industries, sustainability is achieved through efficiency, reliability, and recyclability.

决策者的关键要点

Durability reduces waste → Longer lifespan means fewer replacements.

Energy efficiency saves costs → Reliable seals improve performance.

Recyclability supports sustainability → End-of-life rings can be reused.

Environmental protection is ensured → Strong seals prevent harmful leaks.

For decision-makers, choosing tungsten carbide seal rings is not just about performance—it is about aligning with sustainability goals.

结论

Tungsten carbide seal rings play a critical role in sustainable sealing solutions. Their durability, efficiency, recyclability, and reliability make them ideal for industries that want to lower costs while meeting environmental standards.

For companies in power generation, marine, chemical, and oil and gas industries, investing in tungsten carbide seal rings is both a technical solution and a sustainability strategy.

如果您想了解任何公司的更多详细信息,请随时 联系我们。