In the industrial world, machines and tools face constant stress, friction, and heat. Parts that cannot handle these conditions wear out quickly, causing downtime and high replacement costs.

That is why many companies rely on tungsten carbide — a material famous for its exceptional durability.

This article explains the science that makes tungsten carbide so tough, why it lasts longer than most other materials, and how industries benefit from using it.

什么是碳化钨?

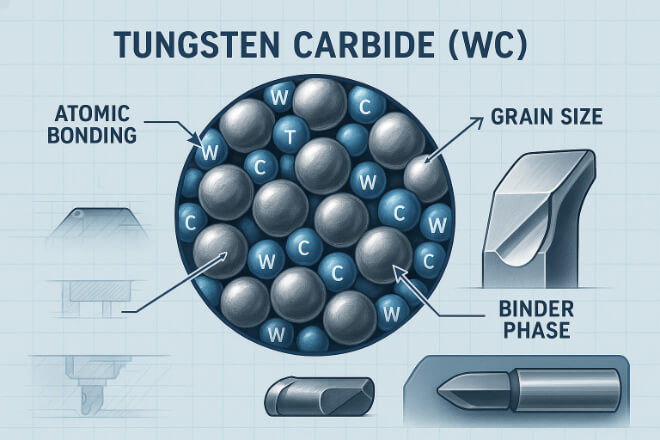

Tungsten carbide is a chemical compound made from tungsten (W) and carbon (C) atoms. When combined, they create a very hard and dense material.

Most industrial tungsten carbide parts also contain a metal binder, usually cobalt or nickel, to add toughness.

碳化钨的主要特点:

Extremely hard – almost as hard as diamond

High density – heavier than steel

Strong and tough – resists cracks and breaks

耐磨 – lasts longer under stress

The Science of Its Durability

The durability of tungsten carbide comes from the structure of its atoms and the way it is manufactured.

1). Atomic Bonding

Tungsten and carbon form strong covalent bonds, creating a crystal structure that is extremely hard to break. This structure is what gives tungsten carbide its 硬度.

2). Grain Size

Smaller grain sizes make the material harder and more resistant to wear. Fine-grain carbides are used in precision 切削工具 where sharp edges are essential.

3). Binder Phase

The metal binder (cobalt or nickel) holds the hard carbide grains together. More binder means greater toughness but slightly less hardness. Less binder means more hardness but less impact resistance.

Hardness: The Key to Long Life

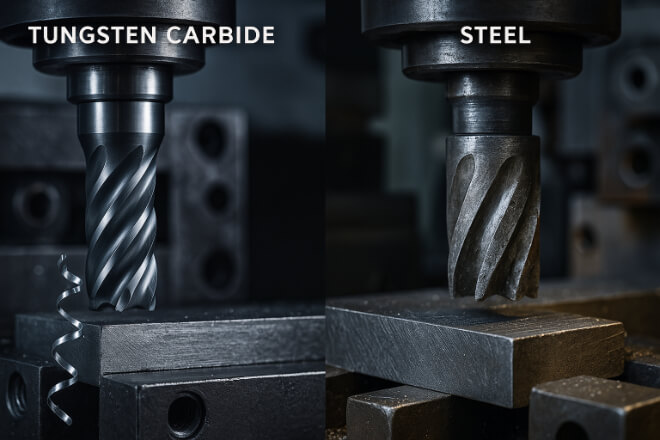

Hardness is the ability of a material to resist scratching and indentation. Tungsten carbide scores about 8.5–9 on the Mohs scale, just below diamond.

This hardness allows cutting tools, mining bits, and wear parts to keep their shape and sharpness much longer than steel or other materials.

In high-speed machining, this means fewer tool changes and less downtime.

Wear Resistance: Fighting Friction

耐磨性 is critical in industries like mining, 石油和天然气, and manufacturing. Tungsten carbide resists abrasion because:

Hard grains prevent cutting by other materials.

The dense structure resists surface damage.

It keeps its hardness even at high temperatures.

Compared to tool steel, tungsten carbide can last 10 to 20 times longer in many applications.

Heat Resistance: Working in Extreme Conditions

In machining or drilling, heat builds up quickly. Many materials lose 硬度 when they get hot, but tungsten carbide stays hard up to 1,000°C (1,832°F).

This heat resistance is why tungsten carbide tools are used for high-speed cutting, metal forming, and mining in extreme environments.

Corrosion Resistance: Surviving Harsh Environments

Tungsten carbide resists many chemicals, making it ideal for applications in oil fields, chemical plants, and marine environments.

While pure tungsten carbide is very corrosion-resistant, the binder metal can be affected, so special grades with nickel binders are used in highly corrosive settings.

Toughness: Handling Impact and Shock

While hardness is important, materials also need 韧性 — the ability to absorb energy without breaking.

The binder in tungsten carbide provides toughness, allowing it to handle vibration, shock, and impact in tools and wear parts.

Industrial Applications of Tungsten Carbide’s Durability

Tungsten carbide’s combination of 硬度, 耐磨性, heat resistance, and 韧性 makes it essential in many industries:

Metal Cutting Tools – Inserts, end mills, drills

Mining Tools – Drill bits, cutter picks, crusher tips

Oil & Gas Equipment – Valve seats, pump seals

Construction Tools – Road milling teeth, excavation tools

Wear Parts – Bushings, nozzles, dies

Comparison with Other Durable Materials

| 材料 | 硬度 | 耐磨性 | 耐热性 |

|---|---|---|---|

| 碳化钨 | 非常高 | 出色的 | 出色的 |

| Tool Steel | 中等的 | 好的 | Fair |

| 陶瓷 | 非常高 | 出色的 | 好的 |

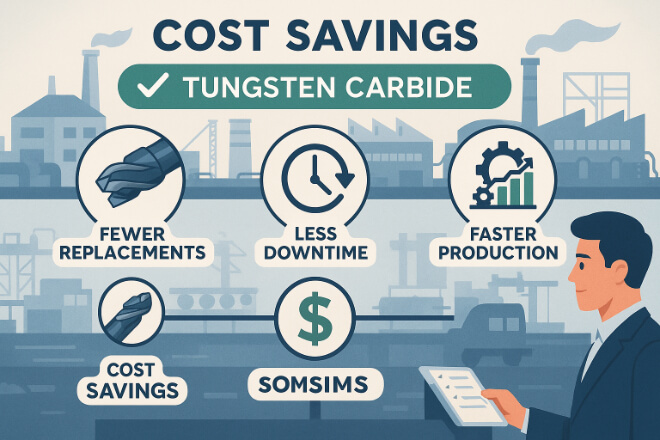

How Durability Saves Costs for Industries

Although tungsten carbide components cost more upfront, they save money in the long run by:

Reducing replacement frequency

Minimizing downtime

Lowering maintenance costs

Improving production speed and consistency

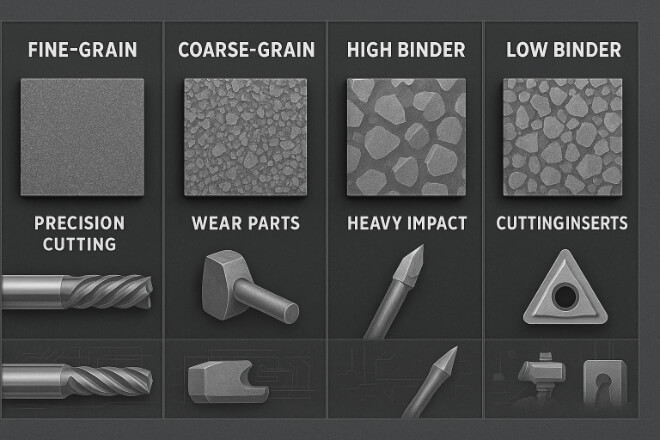

Choosing the Right Grade of Tungsten Carbide

Not all tungsten carbide is the same. Choosing the right grade for your application ensures maximum durability.

Fine-Grain Grades – Best for wear resistance and precision tools.

Coarse-Grain Grades – Better for heavy impact applications.

High Binder Content – More toughness, less hardness.

Low Binder Content – More hardness, less toughness.

Maintenance Tips to Preserve Durability

Even durable materials benefit from proper maintenance:

| Tip | 益处 |

|---|---|

| Regular Inspections | Identify early wear and prevent failure |

| Proper Lubrication | Reduce friction and heat buildup |

| Correct Handling | Prevent chipping or cracking |

| Cleaning After Use | Remove debris and corrosive agents |

Future Innovations in Tungsten Carbide Durability

Research is focused on improving tungsten carbide through:

Nanostructured carbides for higher strength

Advanced coatings to reduce friction

Recycling programs to recover tungsten from used tools

These innovations will make tungsten carbide even more cost-effective and sustainable.

结论

Tungsten carbide’s exceptional durability comes from its atomic structure, hardness, toughness, and resistance to heat and corrosion.

For industries that rely on high-performance tools and parts, it offers a way to cut costs, reduce downtime, and improve productivity.

By understanding the science behind its durability, decision-makers can make better choices about where and how to use tungsten carbide in their operations.

如果您想了解任何公司的更多详细信息,请随时 联系我们。