1. 为什么工业界使用碳化钨切削刀具

碳化钨不仅坚硬,而且强度大约是钢的两倍,并且比大多数材料更能承受高温、高速和重载。

这使得它非常适合需要使用寿命更长、保持更锋利的切割工具。

在注重工具可靠性和一致性能的行业中,硬质合金工具可提供出色的效果。

碳化钨刀具的主要优点包括:

极长的刀具寿命,减少刀具更换频率

具有优异的耐磨性、抗变形性和耐热性

能够切割坚硬、磨蚀性或特殊材料,且磨损极小

切割更清洁、更精确,减少二次精加工的需要

与高速自动化加工系统的兼容性

由于这些特性,越来越多的行业正在用硬质合金替代品取代传统的高速钢刀具。

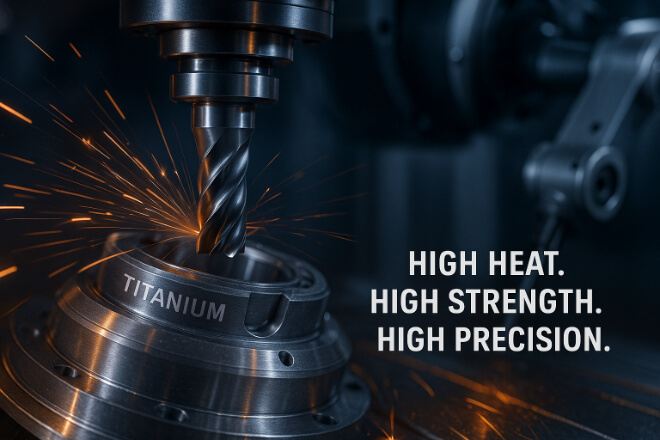

2.航空航天工业

为什么硬质合金工具必不可少:航空航天零件通常由钛、因科镍合金和硬化不锈钢等超坚韧的金属制成。

这些材料很难切割,升温很快,并且会很快磨损常规工具。

硬质合金刀具的帮助在于:

承受极端温度而不软化

精确切割钛和因科镍合金,无碎裂

为高价值零件提供严格的公差

降低自动化生产线中的工具故障率

从涡轮叶片到发动机支架和起落架部件,碳化钨切削刀具在航空航天加工中发挥着至关重要的作用。

3.汽车行业

重要性:在汽车制造业中,速度和准确性就是一切。

工厂每天生产数千个零件(刹车盘、变速箱壳体、发动机盖),并且需要不会减速或快速磨损的工具。

硬质合金刀具通过以下方式提高生产率:

切割速度更快、更清洁,即使在合金钢等硬质金属上也能实现

在连续大批量运行中提供可靠的性能

由于刀具寿命延长,减少了停机时间

支持 CNC 生产线自动化,实现一致的输出

无论是铣削精密部件还是钻安装孔,硬质合金刀具都能让汽车制造商保持速度和准确性。

4.石油和天然气工业

切割坚硬材料:在石油钻探和管道作业中,环境要求很高——必须在高压和极端温度下准确切割 Inconel、双相不锈钢和合金管等材料。

碳化钨工具用于:

精密加工阀门零件、法兰和压力配件

无需刀具磨损即可切割耐腐蚀合金

在干燥和润滑环境中都能可靠运行

最大限度延长钻机和现场服务设备的正常运行时间

在这个行业中,工具故障可能会导致严重的停机和安全问题。

这就是为什么许多油田操作员依赖专为极端工作循环设计的硬质合金工具。

5.医疗器械制造

精度为何重要:医疗器械和植入物需要微米级的精度,并且通常由不锈钢、钴铬合金和钛等高难度材料制成。任何偏差都可能影响患者的安全。

硬质合金切削刀具通过以下方式支持医疗制造:

实现超精密切割,毛刺极少

保持骨科植入物和手术器械的精确公差

减少小零件加工时的热变形

执行微钻孔和轮廓加工等精细任务

在医疗生产中,不容有任何差错。硬质合金刀具让制造商充满信心,满足严格的法规和质量标准。

6.模具行业

高精度和可重复性:模具制造商需要能够处理极硬工具钢的工具,同时还能生产出高度详细的型腔、轮廓和雕刻。

碳化钨工具的帮助在于:

在较长的生产周期内保持尺寸精度

轻松切割硬化钢块和石墨电极

通过严格的切屑控制支持高速加工

降低粗加工和精加工过程中崩刃的风险

从压铸模具到注塑模具和精密冲压模具,硬质合金刀具可确保质量和可重复性。

7.木工和家具制造

是的——硬质合金也用于木材加工:尽管木材比金属软,但木工仍会面临诸多挑战,例如树脂堆积、胶水磨损以及研磨复合板。在这些情况下,高速钢刀具会很快钝化。

碳化物是优选的,因为它:

在磨料或树脂材料上保持更长时间的锋利

切割中密度纤维板、胶合板和层压板,不会产生碎裂

提供光滑的边缘和专业的饰面

减少自动化家具生产线中的工具更换

从路由器钻头到圆锯片,硬质合金是现代木工操作的首选。

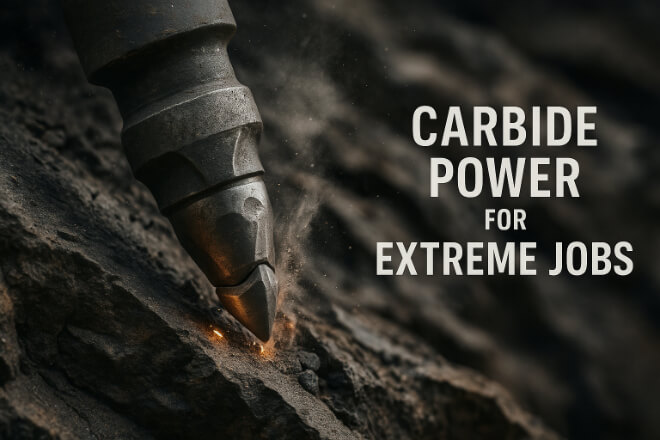

8.采矿和建筑业

专为承受冲击而设计:在采矿和基础设施项目中,工具会面临持续的冲击、磨损和灰尘。

用于道路铣削、隧道掘进或钻孔的设备必须配备高性能切削刃。

碳化钨工具用于:

承受反复冲击的凿岩机和采矿镐

隧道掘进机刀具和挖沟齿

混凝土锯片和道路重铺钻头

需要极高耐用性的土方部件

在这些行业中,硬质合金的耐磨性至关重要,因为硬质合金的磨损会导致代价高昂的机器停机和安全风险。

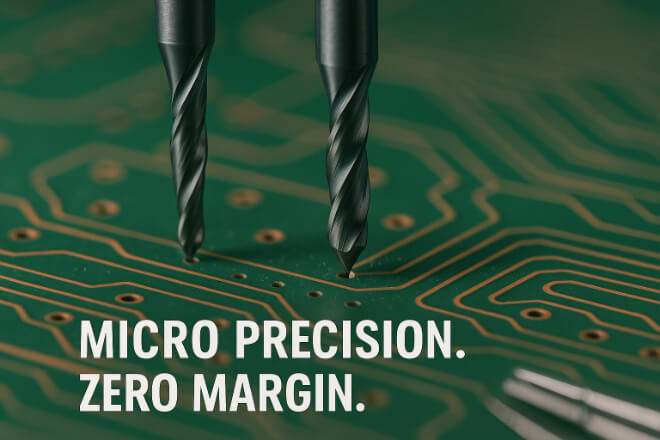

9. 电子和 PCB 制造

微小切割,高精度:印刷电路板 (PCB) 和微电子元件需要极小且精确的切割。

硬质合金微型刀具是理想的选择,因为它们即使在微小的尺寸下也能保持锋利。

硬质合金微型刀具非常适合:

通过 FR4 和铜层进行微钻孔

铣削紧密的走线和微型连接器

确保切割过程中无毛刺或分层

在大规模生产中提供稳定且可重复的结果

在电子行业,钝的或变形的刀具可能会损坏敏感元件。硬质合金刀具可保持高精度,并降低缺陷率。

10.通用数控加工

对于大大小小的机械车间:无论是大型工厂还是本地原型车间,数控机床都依赖于可靠且多功能的工具。

碳化钨工具在各种作业中都能提供稳定的性能。

为什么机械师更喜欢它们:

实现更高的进给率、转速和切削深度

在多轴机器上提供更长的不间断运行时间

通过最大限度延长刀具寿命来降低每个零件的成本

适用于铝、钢、不锈钢和复合材料

11.珠宝和钟表制造

精致的材料、完美的剪裁:在奢侈品制造中,对细节的关注至关重要。

碳化钨工具通常用于贵金属、石材和精密部件的微加工。

碳化物有助于:

保持锋利的边缘以便在黄金和铂金上雕刻

对手表齿轮和表圈进行微铣削

切割坚硬的宝石,不会开裂或碎裂

对精细且贵重的材料提供可重复的结果

珠宝和钟表制造依赖于硬质合金工具的质量、可重复性和精细度。

最后的想法

几乎每个主要行业都使用碳化钨切削刀具,因为它们更优质:更坚硬、更快、更耐用。

从航空航天到家具,硬质合金使加工变得更容易、更清洁、更具成本效益。

如果您仍然只使用 HSS 刀具,那么现在可能是升级的时候了——特别是当您切割硬质材料、运行 CNC 或需要更长的刀具寿命时。

最终,无论您需要标准选项还是完全定制的刀具, 雷托普兹 有你需要的东西。