In modern manufacturing, mining, and material processing, grinding and milling are vital steps. The tools used in these processes directly affect product quality, production cost, and efficiency.

Among the different types of grinding media, tungsten carbide balls stand out for their strength, 硬度, 和 耐磨性。

This article explains what makes tungsten carbide balls so effective, how they are used in grinding and milling, and why many industries now depend on them.

For decision-makers, the goal is clear: use the right grinding media to improve output and lower costs.

什么是碳化钨球?

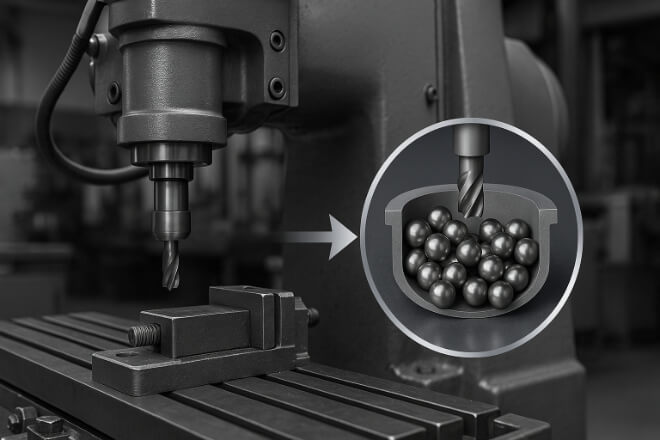

Tungsten carbide balls are small, spherical components made from 碳化钨粉 and a metallic binder (often cobalt or nickel).

They are produced through powder pressing, sintering, and precise grinding.

Key characteristics include:

Extremely high 硬度 (close to diamond on the hardness scale).

出色的 耐磨性 in abrasive environments.

High density, which delivers more grinding energy per strike.

Resistance to heat and deformation under stress.

These properties make tungsten carbide balls much more reliable than steel or ceramic balls when consistent particle size reduction is required.

Why Use Tungsten Carbide Balls in Grinding?

In grinding and milling, the media transfers force to break down materials into finer particles.

The better the media, the more efficient the process. Tungsten carbide balls provide:

Higher impact energy due to their density.

Less wear and contamination compared to softer media.

Consistent results in both wet and dry grinding.

Longer lifespan, meaning fewer replacements and lower operating costs.

For industries dealing with hard or abrasive materials, carbide balls reduce downtime and improve productivity.

Applications in Different Industries

Tungsten carbide balls are used in:

矿业 and minerals: Crushing ores and grinding rocks.

Cement and construction: Fine grinding of raw materials.

Pharmaceuticals: Creating fine powders for drug formulations.

Chemicals and pigments: Ensuring uniform mixing and particle size.

Electronics: Preparing powders for advanced ceramics and batteries.

Wherever precision and durability are needed, carbide balls provide a dependable solution.

Performance Compared to Other Media

To understand their value, here’s a comparison:

| 财产 | 钢球 | 陶瓷球 | 碳化钨球 |

|---|---|---|---|

| 硬度 | 中等的 | 高的 | 非常高 |

| 密度 | 7.8 g/cm³ | 6.0 g/cm³ | 14.5 g/cm³ |

| 耐磨性 | 低至中等 | 高的 | 出色的 |

| 耐热性 | 缓和 | 高的 | 出色的 |

| 成本 | 低的 | 中等的 | 中高 |

| Best Use Case | General grinding | High-purity applications | Hard, abrasive materials |

This shows why many industries invest in tungsten carbide despite its higher price. The longer life and higher efficiency make it cost-effective over time.

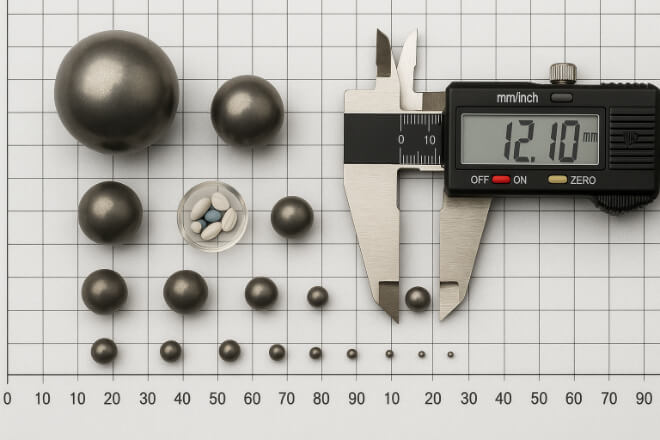

Selecting the Right Ball Size

Ball size matters. Larger balls generate more impact, while smaller ones provide finer grinding.

Tungsten carbide balls are available in many diameters, from a fraction of a millimeter up to several centimeters.

Decision-makers should match ball size to:

The material being processed.

The target particle size.

The type of mill being used.

Maintenance and Handling

Although tungsten carbide is tough, proper care extends its life:

Store balls in a dry, clean environment to avoid contamination.

Regularly check for cracks or surface wear.

Replace worn balls before they reduce grinding efficiency.

Keep them separate from softer media to avoid damaging them.

Why Decision-Makers Should Care

For executives and managers, choosing tungsten carbide grinding media is not just a technical choice. It’s a business strategy. It means:

More stable production.

Lower total cost of ownership.

Higher product quality.

Reduced downtime.

The upfront investment pays off in long-term efficiency and reliability.

结论

Tungsten carbide balls are a smart solution for grinding and milling in industries that value precision, strength, and cost savings. They outperform steel and ceramic alternatives in most demanding environments.

For decision-makers, the message is clear: investing in tungsten carbide grinding media means investing in better performance, longer life, and stronger returns.

如果您想了解任何公司的更多详细信息,请随时 联系我们。