In today’s manufacturing world, companies in the paper, textile, and packaging industries face strong competition.

They need machines that can run for long hours, produce high-quality products, and keep costs low.

One of the biggest challenges is dealing with wear and tear on machine parts. This is where 碳化钨耐磨件 play a key role.

Tungsten carbide is known for its 硬度, strength, and resistance to wear, heat, and corrosion.

These qualities make it ideal for industries where machinery works in demanding conditions.

In this article, we will explore how tungsten carbide is used in paper, textile, and packaging machinery, and why it has become the go-to material for many manufacturers.

Why Tungsten Carbide is the Perfect Choice

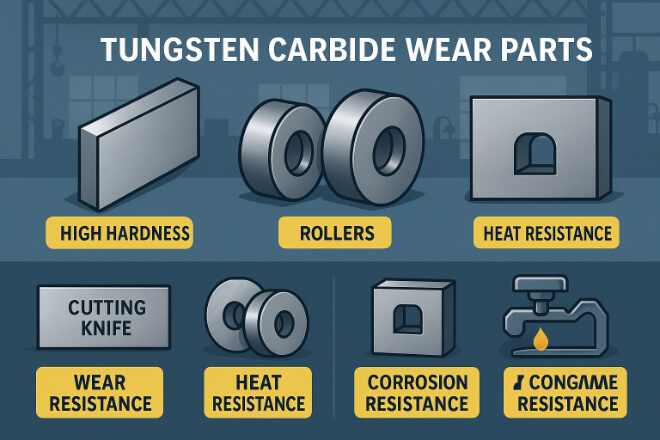

Tungsten carbide wear parts are popular because they last much longer than steel or other materials. They provide:

高的 硬度 for resisting abrasion.

出色的 耐磨性 to reduce replacement costs.

Good heat resistance for high-speed operations.

Corrosion resistance in humid or chemical environments.

These qualities make them perfect for industries that run machines at high speeds and need continuous operation without frequent breakdowns.

Applications in the Paper Industry

The paper industry has many processes where tungsten carbide components can make a big difference.

Common tungsten carbide parts used in paper machinery include:

| 应用领域 | Tungsten Carbide Component | 益处 |

|---|---|---|

| Paper cutting | Knives, slitters | Long-lasting sharpness, clean cuts |

| Paper coating | Rollers | Smooth surface, wear resistance |

| Pulp processing | 耐磨板 | Protection from abrasion |

| Embossing | 模具 | Precise patterns without wear |

In paper production, cutting precision is critical to avoid waste. Tungsten carbide cutting knives stay sharp for much longer, reducing downtime for blade changes.

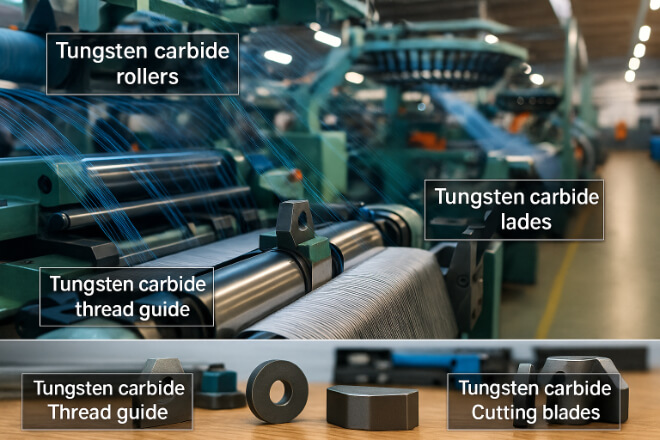

Applications in the Textile Industry

The textile industry uses machinery for weaving, knitting, finishing, and printing fabrics.

These machines often work with abrasive fibers like polyester or blends, which can quickly wear down ordinary parts.

Key tungsten carbide applications in textile machines:

Thread guides and eyelets – Prevent wear from high-speed yarn movement.

Cutting blades – Cleanly cut fabrics without fraying.

Rollers – Handle abrasive fibers without damage.

By using tungsten carbide, textile manufacturers can improve machine uptime and maintain consistent product quality.

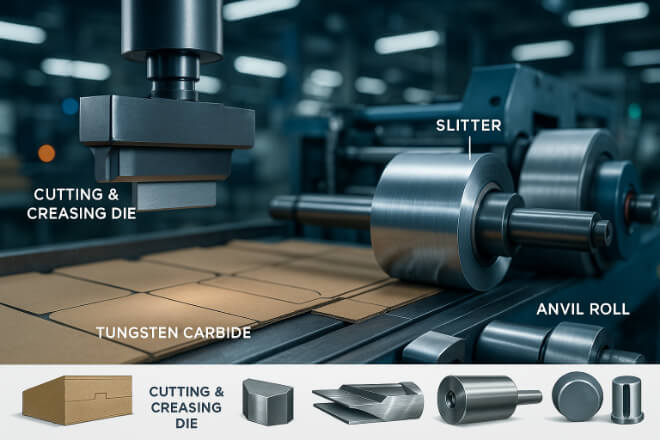

Applications in the Packaging Industry

The packaging industry works with materials like cardboard, plastics, and laminates, often at high speeds. Tungsten carbide helps in:

Cutting and creasing dies – Keep sharp edges for precise folding.

Anvil rolls – Resist wear from repeated cutting actions.

Slitters – Cut packaging films with clean edges.

For example, in corrugated box manufacturing, tungsten carbide slitters can last up to 10 times longer than steel slitters.

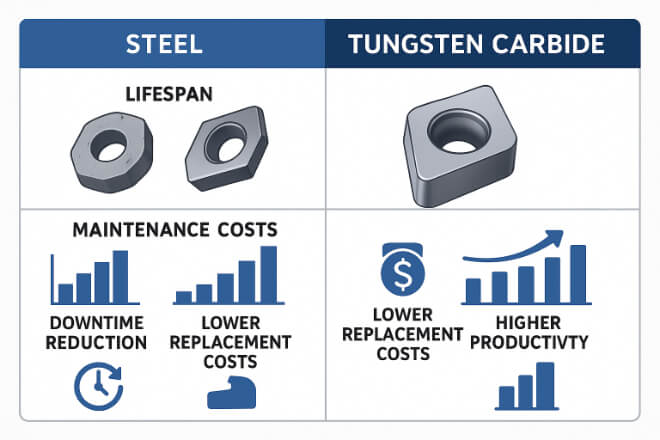

Cost Benefits and ROI

Although tungsten carbide parts have a higher initial cost, they often save money in the long run. Here’s why:

Fewer replacements – Less downtime and labor.

Better quality products – Reduced waste.

Longer maintenance cycles – Increased machine productivity.

Example ROI:

If a steel cutting knife lasts 2 weeks but a tungsten carbide knife lasts 12 weeks, the savings in downtime and replacement costs can be substantial.

Maintenance Tips for Maximum Life

To get the best value from tungsten carbide parts:

Keep machines well-lubricated.

Avoid sudden impacts that can chip edges.

Store spare parts in a dry place to prevent corrosion.

Work with a reliable supplier for quality components.

Future Trends

Manufacturers are now experimenting with coatings on tungsten carbide to make it even more resistant to extreme wear and corrosion.

We can also expect more custom-designed carbide parts for specific applications in paper, textile, and packaging machinery.

结论

For decision-makers in the paper, textile, and packaging industries, tungsten carbide wear parts offer a way to cut costs, improve quality, and extend machine life.

Investing in these components can help companies stay competitive in a fast-moving market.

If your business relies on continuous production, switching to tungsten carbide may be one of the smartest moves you make.

如果您想了解任何公司的更多详细信息,请随时 联系我们。