Cryogenic and extreme cold environments—such as liquefied natural gas (LNG) plants, 航天 testing facilities, scientific labs, and deep-sea systems—require sealing solutions that can perform reliably at very low temperatures.

In these environments, materials become brittle, fluids behave differently, and any failure can cause costly downtime or safety hazards.

碳化钨密封环 are a trusted choice for pumps, compressors, and turbines operating in these harsh conditions.

This article explains their properties, advantages, applications, and best practices for decision-makers.

Challenges of Cryogenic and Extreme Cold Conditions

Operating at temperatures as low as -196 °C (-320 °F) creates challenges:

Material brittleness → Metals and plastics can crack or deform.

Thermal contraction → Components shrink, causing misalignment.

Lubrication issues → Fluids thicken or freeze, increasing friction.

Seal failure risks → Even small leaks can cause dangerous situations.

停机成本 → Repairs at cryogenic facilities are expensive.

碳化钨密封环的性能

Tungsten carbide is a composite of tungsten and carbon, bonded with cobalt or nickel. Its properties make it ideal for extreme cold:

钴结合碳化钨与镍结合碳化钨

1). 钴结碳化钨

Greater impact resistance.

Suitable for pumps and compressors exposed to vibration.

2). 镍结碳化钨

优越的 耐腐蚀。

Best for cryogenic systems handling oxygen, hydrogen, or chemical-rich fluids.

优于其他密封材料

| 特征 | 碳化钨 | 陶瓷制品 | 钢 |

|---|---|---|---|

| Low-Temperature Toughness | 出色的 | 低、脆 | 缓和 |

| 耐磨性 | 出色的 | 缓和 | 贫穷的 |

| 耐腐蚀 | 高(镍等级) | 非常好 | 低的 |

| Thermal Contraction | 低的 | 缓和 | 高的 |

| 使用寿命 | 持久 | 缓和 | 短的 |

Applications in Cryogenic and Cold Environments

碳化钨密封环 are widely used in:

LNG pumps and compressors → Ensure leak-free transfer of liquefied gases.

Aerospace cryogenic testing systems → Handle extreme cold during rocket or satellite testing.

Scientific laboratories → Maintain seal integrity in liquid nitrogen systems.

Marine deep-sea equipment → Resist high pressure and freezing seawater.

Hydrogen fuel systems → Provide safe sealing for clean energy applications.

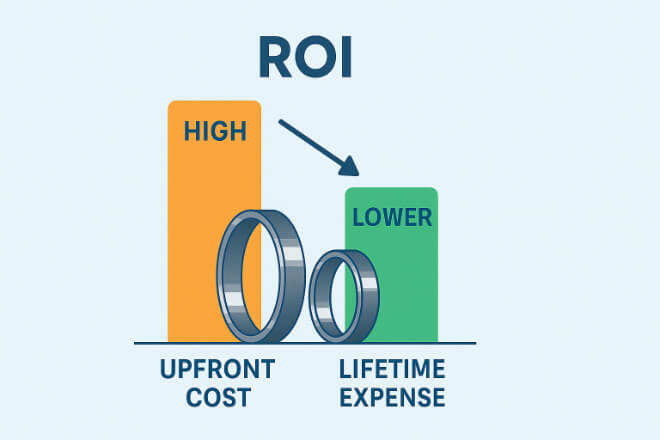

成本与长期价值

While tungsten carbide seal rings have a higher upfront price, they:

通过延长持续时间来减少停机时间。

减少更换次数,降低维护成本。

Protect critical equipment from leaks and damage.

Deliver better ROI in high-risk, cold environments.

环境和安全效益

防止泄漏 → Reduces risk of environmental contamination.

可回收材料 → Supports sustainability goals.

提高效率 → Leak-free systems consume less energy.

使用碳化钨密封环的最佳实践

Match binder to environment → Nickel for corrosive cryogenic fluids, cobalt for high vibration.

Use proper installation techniques → 避免划痕或错位。

定期检查 → Spot wear or contraction damage early.

与经验丰富的供应商合作 → Ensure correct specifications for cryogenic conditions.

Plan maintenance schedules → Avoid unplanned shutdowns in critical systems.

决策者的关键要点

Tungsten carbide seal rings are the best choice for cryogenic and extreme cold applications.

Their low thermal expansion, 耐腐蚀性, 和 韧性 prevent leaks and damage.

Correct binder selection (nickel or cobalt) maximizes reliability.

Investing in tungsten carbide reduces downtime, cost, and environmental risks.

结论

In cryogenic and extreme cold systems, seal reliability is critical. Tungsten carbide seal rings provide unmatched performance, ensuring pumps, compressors, and turbines remain leak-free even under severe conditions.

For decision-makers, selecting tungsten carbide is a strategic investment in safety, efficiency, and sustainability.

如果您想了解任何公司的更多详细信息,请随时 联系我们。