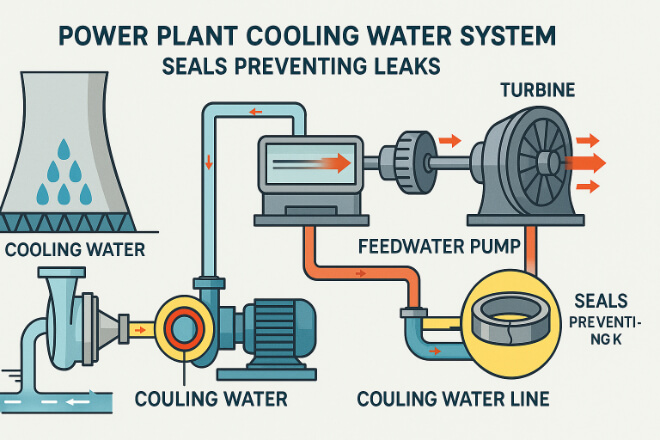

Power plants rely on cooling water systems to manage heat and keep turbines, pumps, and generators running safely.

Any leak or failure in these systems can lead to downtime, efficiency loss, or environmental damage.

碳化钨密封环 are one of the most reliable materials for pumps and compressors in cooling water systems.

This article explains why they are essential, their benefits, and how to use them effectively.

Why Cooling Water Systems Need Reliable Seals

Prevent leaks → Protect equipment and reduce water loss.

Maintain efficiency → Proper seals help pumps operate at full performance.

减少停机时间 → Reliable seals minimize unplanned maintenance.

Avoid contamination → Prevents cooling water from mixing with other fluids.

Protect the environment → Stops harmful discharges into natural water sources.

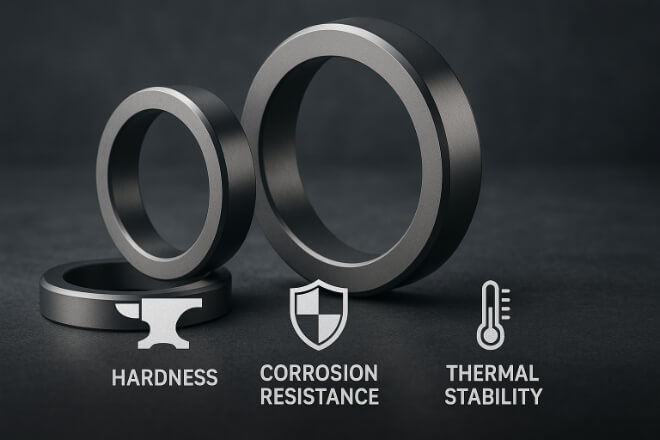

碳化钨密封环的关键特性

Tungsten carbide is a compound of tungsten and carbon, bonded with cobalt or nickel. It offers:

优于其他密封材料

| 特征 | 碳化钨 | 陶瓷制品 | 钢 |

|---|---|---|---|

| 耐磨性 | 非常适合磨料 | 缓和 | 贫穷的 |

| 耐腐蚀 | 高(镍等级) | 非常好 | 低的 |

| 韧性 | 高,抗冲击 | 低、脆 | 缓和 |

| Thermal Performance | Excellent at high heat | 好的 | 缓和 |

| 使用寿命 | 持久 | 缓和 | 短的 |

Applications in Power Plant Cooling Water Systems

碳化钨密封环广泛应用于:

Main cooling water pumps → Ensure reliable, leak-free operation.

Circulating pumps → Maintain water movement for turbine efficiency.

Auxiliary systems → Protect small pumps in control circuits.

Brackish water systems → Resist corrosion in coastal plants.

Backup generators → Provide sealing under varying temperatures and pressures.

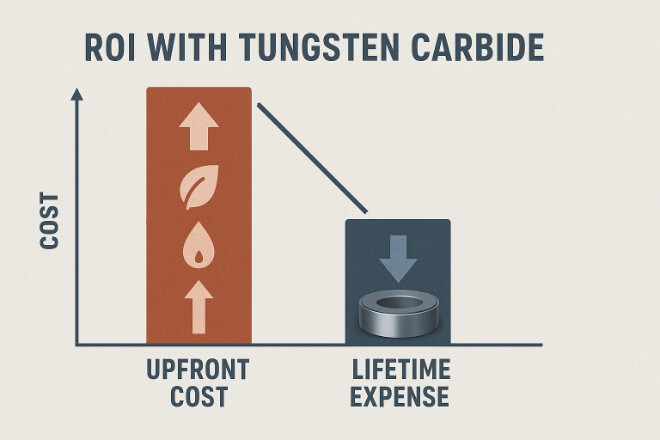

成本与长期价值

Although tungsten carbide seal rings cost more upfront:

减少停机时间 → Fewer failures mean less lost production.

Lower maintenance → Longer service life reduces labor and spare parts.

保护设备 → Prevents damage to expensive pumps and turbines.

提高投资回报率 → Long-term savings offset initial costs.

环境和安全效益

防止泄漏 → Protects local water sources and ecosystems.

可回收材料 → Supports power plants’ sustainability goals.

Efficient performance → Reduces wasted energy in pumps and compressors.

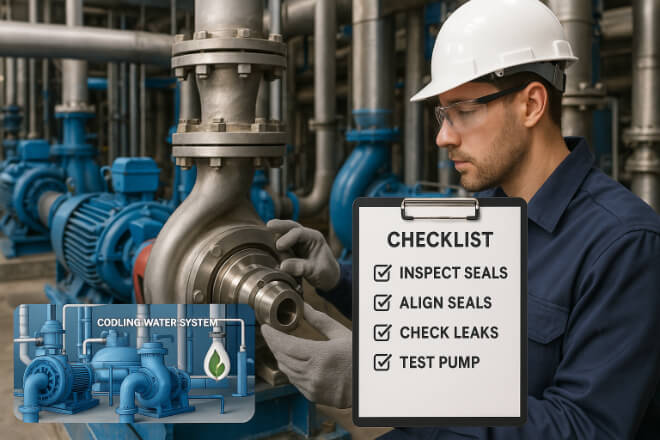

使用碳化钨密封环的最佳实践

选择合适的活页夹 → Nickel for brackish or chemical-rich water, cobalt for vibration-heavy pumps.

定期检查密封件 → 检测早期磨损以防止故障。

Ensure proper installation → Avoid scratches or misalignment during assembly.

Maintain proper lubrication → Prevent dry running that can damage seals.

Work with trusted suppliers → Get quality materials and accurate specifications.

结论

Power plant cooling water systems demand seals that can perform under pressure, temperature shifts, and corrosive conditions.

Tungsten carbide seal rings deliver the strength and reliability required to keep operations efficient and safe.

For decision-makers, investing in tungsten carbide ensures long-term savings, environmental protection, and operational reliability.

如果您想了解任何公司的更多详细信息,请随时 联系我们。