对于工业泵、搅拌器和涡轮机来说,泥浆和磨蚀性流体是最具挑战性的材料之一。

这些液体含有沙子、淤泥或矿物质等固体颗粒,会迅速损坏设备。

可靠的密封系统对于防止泄漏、减少维护和保持平稳运行至关重要。

在可用的材料中, 碳化钨密封环 是处理泥浆和磨料流体的最佳选择之一。

本文解释了原因,将它们与其他方案进行了比较,并为决策者提供了建议。

泥浆和磨料流体处理的挑战

磨蚀性流体会给密封件和设备带来独特的问题:

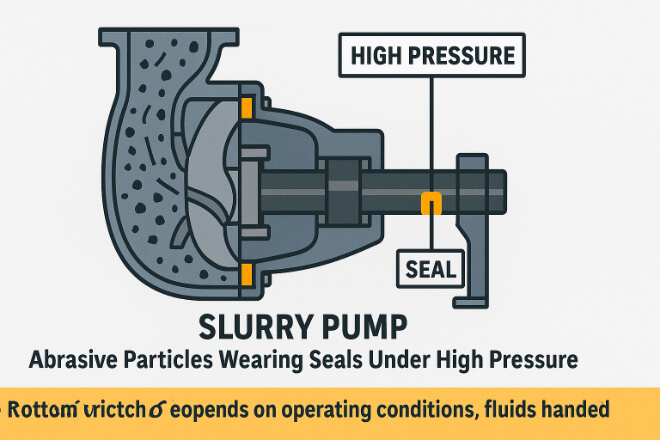

严重磨损 → 固体颗粒会摩擦密封件,造成快速损坏。

高压 → 泥浆泵经常在极端负载下运行。

可变流量 → 不均匀的环境可能会对密封件造成压力。

腐蚀 → 许多泥浆中含有化学物质或海水。

停机成本 → 密封失效会导致生产停止并造成昂贵的维修。

这些挑战需要一种能够承受严重磨损和压力的材料。

优于其他密封材料

| 特征 | 碳化钨 | 陶瓷制品 | 钢 |

|---|---|---|---|

| 耐磨性 | 非常适合磨料 | 浆体中等 | 磨蚀性流体不足 |

| 韧性 | 高;抗冲击/振动 | 低;受冲击时易碎 | 缓和 |

| 耐腐蚀 | 良好;镍结合材料更佳 | 化学性能优异 | 泥浆/化学品不足 |

| 使用寿命 | 在压力下持久 | 缓和 | 在恶劣介质中很短 |

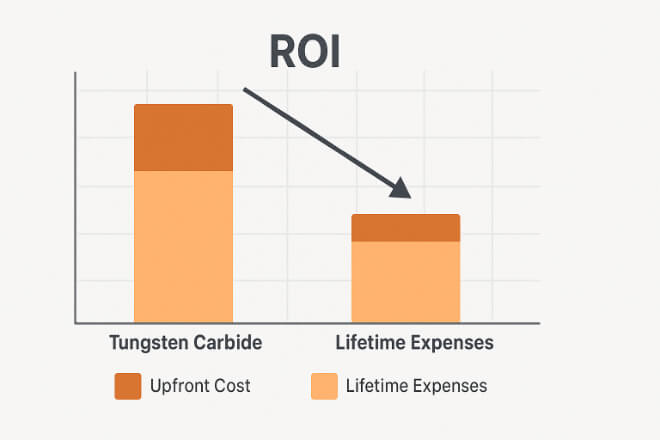

| 成本 | 前期投入更高;投资回报率更高 | 降低初始成本 | 最低初始成本 |

在泥浆和磨料流体系统中的应用

碳化钨密封环广泛应用于:

采矿和疏浚泵——处理高磨蚀性的矿物浆液。

油田钻井系统——管理压力下的磨蚀性钻井液。

废水处理——抵抗充满砂砾的液体的磨损。

海洋和疏浚作业——在沙质海水中提供耐久性。

化工厂——安全处理腐蚀性和磨蚀性混合物。

成本与长期价值

虽然碳化钨密封环的前期成本较高,但它们:

减少停机时间 → 故障和更换频率较低。

降低维护成本 → 减少工时和备件。

保护设备 → 防止泵和轴遭受昂贵的损坏。

提高投资回报率 → 更长的使用寿命可以抵消初始价格。

随着时间的推移,泥浆处理决策者将受益于较低的生命周期成本。

使用碳化钨密封环的最佳实践

为了在磨蚀性环境中最大程度地提高性能:

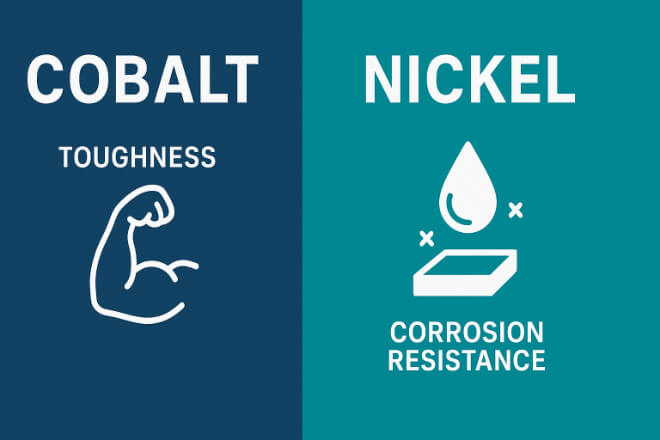

选择正确的活页夹 → 镍用于腐蚀性浆体,钴用于冲击载荷。

小心安装 → 避免因划痕或错位而缩短使用寿命。

使用适当的润滑剂 → 减少热量和摩擦磨损。

定期检查 → 发现早期磨损以防止发生故障。

与经验丰富的供应商合作 → 确保您的系统的材料和设计合适。

环境效益

碳化钨可回收利用。磨损的环可以收集起来并重新加工成新产品,从而减少浪费并支持环境可持续性——这已成为全球各行各业日益重视的重点。

决策者的关键要点

在磨蚀性高压环境中,碳化钨密封环的性能优于钢和陶瓷。

正确的粘合剂(镍或钴)可确保特定条件下的可靠性。

尽管前期成本较高,但碳化钨可以减少停机时间和总体费用。

可回收性增加了可持续性效益。

结论

处理泥浆和磨料流体需要能够承受极端磨损、压力和腐蚀的密封件。

碳化钨密封环具有确保泵、压缩机和涡轮机安全高效运行所需的韧性和耐用性。

对于决策者来说,选择碳化钨是对正常运行时间、性能和可持续性的战略投资。

如果您想了解任何公司的更多详细信息,请随时 联系我们。