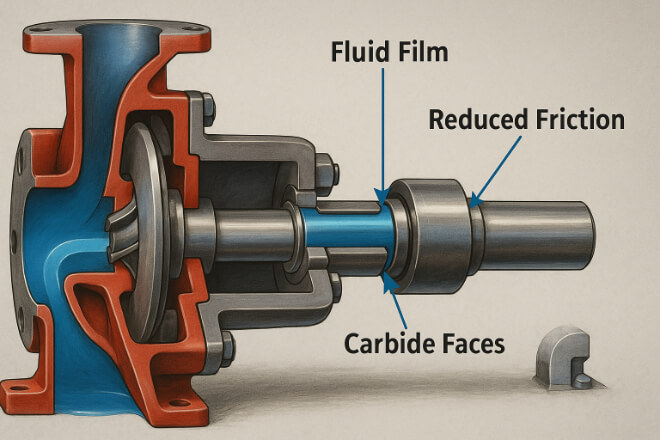

In mechanical seals, the surface finish of carbide faces affects not only leakage control but also lubrication retention.

Two popular finishing approaches—ultra-smooth finishes and micro-pocketed finishes—offer different advantages depending on the operating conditions.

For decision-makers in industries like 石油和天然气, chemical processing, marine systems, and power generation, understanding these finishes helps improve seal performance, equipment life, and cost efficiency.

Why Lubrication Retention Matters

Reduces friction: Adequate lubrication prevents excessive wear.

Improves efficiency: Less friction means lower energy consumption.

Protects seals: Maintains face integrity under pressure and temperature changes.

Prevents dry running: Keeps fluid film stable during startup or low-flow conditions.

What Are Ultra-Smooth Finishes?

Ultra-smooth finishes are polished surfaces with very low Ra values (≤0.1 μm). They minimize friction and create tight seals.

1). 优点

Low friction: Ideal for clean fluids and high-speed applications.

Excellent leakage control: Smooth surfaces reduce fluid escape.

Less particle trapping: Easier to clean and maintain.

2). Limitations

May struggle with lubrication film stability at very low speeds or during startup.

More sensitive to surface damage, requiring careful handling.

3). Best Applications

Pharmaceutical or semiconductor pumps requiring ultra-clean conditions.

High-speed compressors using non-abrasive fluids.

Vacuum systems where leakage must be minimized.

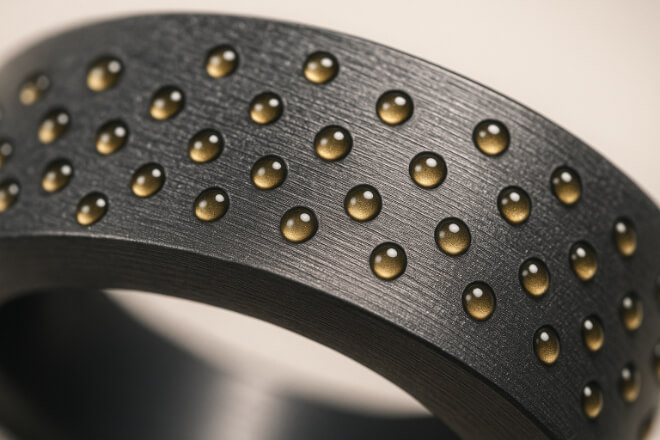

What Are Micro-Pocketed Finishes?

Micro-pocketed finishes use small surface pockets or grooves to retain lubricant.

The Ra value may be slightly higher (0.15–0.3 μm), but these features enhance lubrication under certain conditions.

1). 优点

Improved lubrication retention: Pockets trap fluid, maintaining a lubricating film.

Better performance under low speed or dry-start conditions.

Reduced heat generation in marginal lubrication situations.

2). Limitations

Slightly higher leakage potential compared to ultra-smooth surfaces.

More difficult to clean in ultra-pure applications.

3). Best Applications

Slurry pumps handling abrasive fluids.

Marine ballast pumps operating at variable speeds.

Chemical transfer systems with intermittent flows.

Surface Finish Comparison

| Aspect | Ultra-Smooth Finish | Micro-Pocketed Finish |

|---|---|---|

| Ra Value | ≤0.1 μm | 0.15–0.3 μm |

| Leakage Control | 出色的 | 好的 |

| Lubrication Retention | Fair | 出色的 |

| 最佳应用 | Clean fluids, high speed | Variable speed, abrasive fluids |

Factors to Consider When Choosing a Finish

1). Fluid Type

Clean, non-abrasive fluids → Ultra-smooth finish.

Abrasive or particle-laden fluids → Micro-pocketed finish.

2). Operating Speed

High speed → Ultra-smooth.

Low or variable speed → Micro-pocketed for lubrication stability.

3). System Pressure and Temperature

Extreme pressure or temperature → Use micro-pocketed to prevent dry spots.

4). Maintenance Goals

Systems requiring ultra-clean conditions → Ultra-smooth for easy cleaning.

Pumps exposed to dirt or intermittent operation → Micro-pocketed for extra lubrication retention.

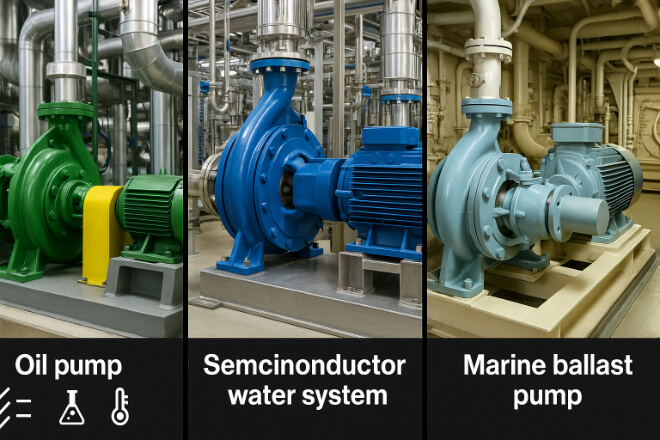

行业应用

石油和天然气 transfer pumps: Micro-pocketed finishes for improved lubrication under fluctuating speeds.

Semiconductor manufacturing: Ultra-smooth finishes for ultra-pure water systems.

Marine ballast systems: Micro-pocketed finishes for varying loads.

Pharmaceutical mixers: Ultra-smooth finishes for contamination control.

Best Practices for Lapping and Polishing Finishes

Use diamond slurry and stable fixtures for uniform Ra.

Check flatness frequently with optical flats.

Alternate polishing directions to prevent uneven grooves.

Clean all components before assembly to avoid scratching or particle trapping.

Common Issues and Solutions

Premature seal failure: Verify that finish type matches operating conditions.

High leakage: Switch from micro-pocketed to ultra-smooth or improve flatness.

Heat buildup: Use micro-pocketed finishes to improve lubrication film stability.

Difficult cleaning: Ultra-smooth surfaces are easier to sanitize.

成本和投资回报率考虑因素

Ultra-smooth finishes may cost more initially but reduce leakage and cleaning time.

Micro-pocketed finishes extend seal life in tough conditions, saving on replacements.

Proper finish selection reduces downtime, improves performance, and increases ROI.

结论

The choice between ultra-smooth and micro-pocketed finishes for carbide faces directly impacts lubrication retention, leakage control, and seal longevity.

Decision-makers should evaluate fluid type, operating speed, pressure, and maintenance requirements to select the right finish. Proper selection ensures efficient, safe, and cost-effective sealing performance.

如果您想了解任何公司的更多详细信息,请随时 联系我们。