碳化钨刀具因其卓越的硬度和耐磨性而广受认可,但其另一项对长期性能同样至关重要的特性是:化学稳定性。无论是在腐蚀性环境中操作、暴露于冷却液中,还是经受高温反应,碳化钨刀具都必须能够抵抗化学降解,以保持其功能。

本文解释了化学稳定性的含义、它对碳化钨工具的重要性以及如何将其设计成现代工具材料。

影响WC工具化学稳定性的关键因素

几种材料和设计的选择决定了碳化钨刀具的化学稳定性:

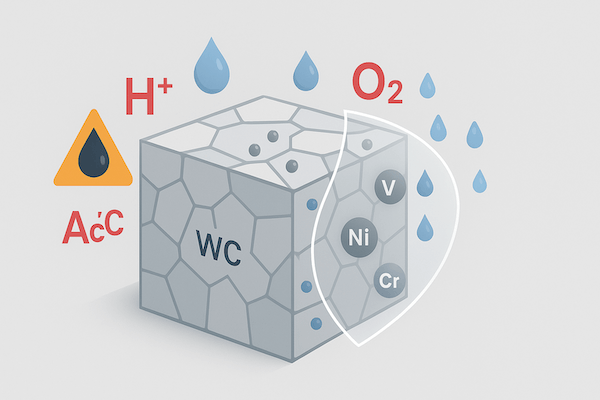

🔹 粘合剂相组成

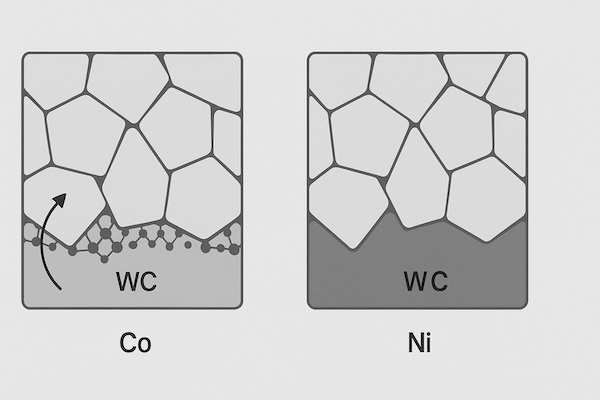

钴在某些环境下具有化学反应性。用镍或钴镍合金替代或改性粘合剂可提高耐腐蚀性。

🔹合金添加剂

Cr(铬)、Mo(钼)和V(钒)等元素形成稳定的碳化物,有助于防止化学侵蚀和氧化。

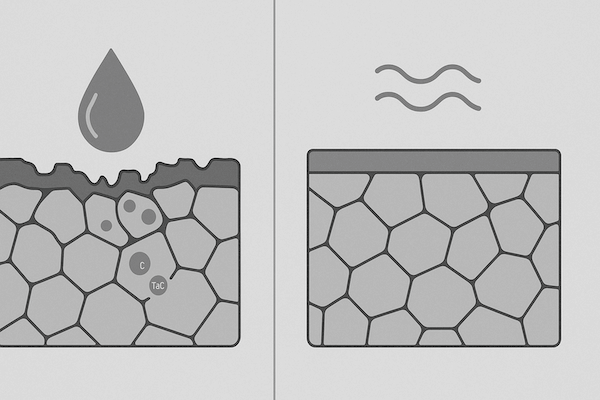

🔹 谷物结构

更细、更均匀的晶粒结构可减少暴露的表面积并更有效地抵抗晶间腐蚀。

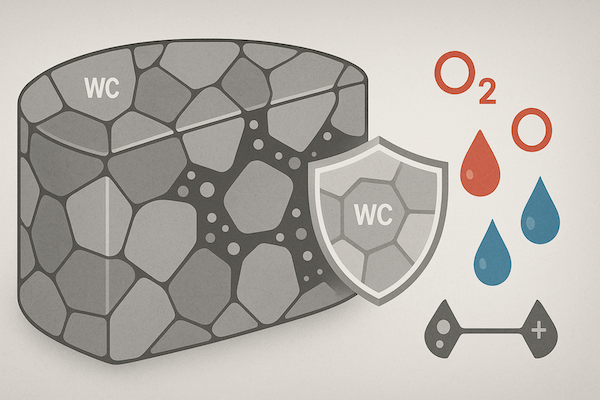

🔹表面涂层

应用 PVD 或 CVD 涂层(例如 TiN、TiAlN、CrN)可形成化学惰性屏障,从而显著增加工具在恶劣环境中的使用寿命。

结论

化学稳定性不仅仅是材料科学的流行术语,更是高性能碳化钨刀具的标志性特征。无论面对高温、腐蚀性流体还是化学磨损,具有卓越化学稳定性的刀具都能延长使用寿命、减少故障并降低运营成本。

通过控制成分、微观结构和表面保护,制造商确保硬质合金刀具满足最具化学腐蚀性的环境的要求,同时又不牺牲性能。