When it comes to cutting tools, tungsten carbide is the go-to material for professionals who need strength, speed, and reliability.

But not all carbide tools are created equal. The grade of tungsten carbide you choose can greatly affect how your tool performs—and how long it lasts.

Whether you’re cutting aluminum, steel, or composites, using the right carbide grade is key to achieving the best results.

This guide helps you understand what carbide grades mean, why they are important, and how to choose the best grade for your job.

1. What Are Tungsten Carbide Grades?

Tungsten carbide grades refer to different mixtures of tungsten carbide and other materials (like cobalt), which affect the tool’s 硬度, strength, toughness, and 耐磨性.

Think of it like choosing the right type of steel: some are great for strength, others for flexibility. With tungsten carbide, the mix determines how the tool behaves.

Basic Ingredients:

Tungsten carbide (WC): The hard particles

Cobalt (Co): The binder that holds the particles together

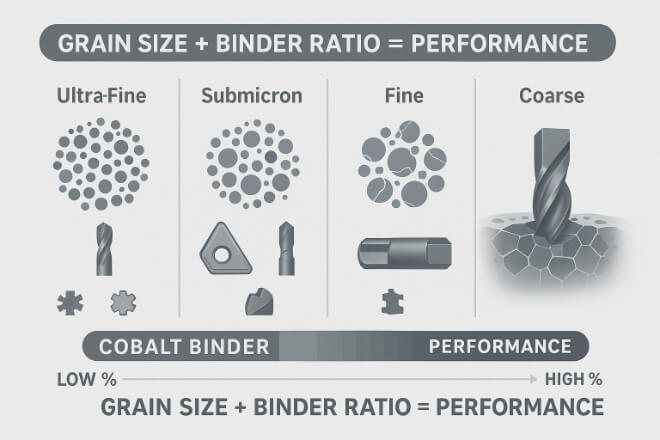

Different ratios and grain sizes create different grades—some better for tough jobs, others better for precise finishing.

2. Why Do Grades Matter?

Using the wrong grade can result in:

Tool breakage

Premature wear

表面光洁度差

Low productivity

Higher costs

On the flip side, the right grade means:

更长的刀具寿命

Better surface quality

Faster machining speeds

Improved dimensional accuracy

That’s why selecting the correct tungsten carbide grade is critical in any machining operation.

3. How Grades Are Classified

Tungsten carbide grades don’t follow a universal code, but most manufacturers use systems based on grain size, binder percentage, and application category. Here’s how they break down:

1). Grain Size (microstructure)

Ultra-fine (<0.5 µm): Great for sharp tools, high 耐磨性, and finishing

Fine (0.5–1.0 µm): Good for moderate wear and strength balance

Medium (1–2 µm): General-purpose, suitable for many jobs

Coarse (>2 µm): Better for toughness, less wear resistance

2). Binder Content (Cobalt %):

6–10% Co: Higher 硬度, lower toughness (best for hard materials)

10–20% Co: Greater toughness, better shock resistance

3). ISO Classification (for inserts):

P-grade: Steel

M-grade: Stainless steel

K-grade: Cast iron

N-grade: Non-ferrous (aluminum, copper)

S-grade: High-temp alloys (Inconel, titanium)

H-grade: Hardened materials

4. Common Tungsten Carbide Grades and Their Uses

Here’s a simplified reference chart showing typical carbide grades and what they’re good for:

| 等级类型 | 粒度 | Cobalt % | 最适合 |

|---|---|---|---|

| Ultra-Fine (UF) | < 0.5 µm | 6–10% | Finishing, sharp edges, aluminum, plastics |

| Fine Grain (F) | 0.5–1 µm | 6–12% | General purpose, light steel, copper |

| Medium Grain (M) | 1–2 µm | 10–15% | Steel, cast iron, versatile applications |

| Coarse Grain (C) | > 2 µm | 15–20% | Heavy-duty, interrupted cuts, impact resistance |

5. Choosing the Right Grade for Your Application

Here’s how to pick the proper carbide grade depending on the material you’re machining:

1). Aluminum & Non-Ferrous Materials

Use ultra-fine grain carbide with polished flutes

Lower cobalt content for sharper edges

Ideal for high RPM and clean finishes

2). Steel (Mild, Alloyed)

Choose medium grain carbide with moderate binder

Look for coatings like TiAlN or AlCrN for heat resistance

3). Stainless Steel

Needs a balance of hardness and toughness

Go with fine grain, 10–15% cobalt

Avoid sharp corners—use rounded profiles

4). Cast Iron

Use harder grades, medium or fine grain

Sharp tools are less effective—opt for edge strength

5). Titanium & High-Temp Alloys

Require ultra-fine carbide with strong coatings

Avoid chip welding with DLC or TiAlN coatings

6). Hardened Steel

Needs low cobalt, high hardness carbide

Often paired with ceramic or PCD tips

6. Coatings Also Matter

Even the best carbide grade needs the right coating to perform well.

Here are some popular coating types used on carbide tools:

| 涂层 | 最适合 | Key Benefits |

|---|---|---|

| 锡 | General use | 硬度增加 |

| 氮化铝钛 | Steel, high-temp alloys | Heat resistance, long tool life |

| 氮化铝钛 | 淬硬钢 | Strong under high heat, dry cutting |

| 扩展内容 | 铝、塑料 | Reduces sticking, smooth cutting |

Tip: Pairing the correct grade + coating is what separates good results from great ones.

7. Why Using the Right Grade Saves You Money

Many shops choose tools based only on cost. But using the wrong grade leads to:

Faster tool wear

Frequent replacements

Poor surface quality

More downtime and rework

The right carbide grade, on the other hand, helps you:

Run at higher speeds

Achieve better finishes

Reduce tool breakage

降低每个零件的成本

Increase your CNC efficiency

So while premium-grade tools might cost more upfront, they save you more in the long run.

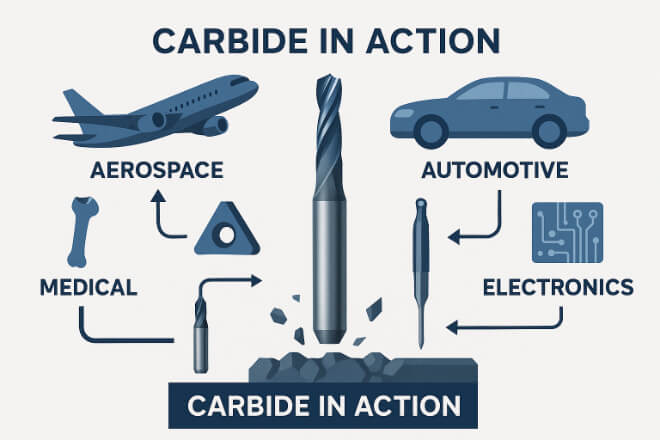

8. Examples from Real Industries

Let’s see how different industries benefit from using the right carbide grades:

1). 航天

Machining titanium and Inconel with ultra-fine grades

Long tool life even under extreme heat

2). 汽车

Coarse grain tools for roughing engine blocks

Fine grain for precision holes and surface finish

3). 医疗的

Micro tools using ultra-fine carbide for bone implants

High sharpness for burr-free cuts

4). Electronics

Finishing copper and plastics with DLC-coated fine grade tools

Burr control and high precision

9. Final Checklist: What to Ask Before You Choose

Before you buy your next cutting tool, ask:

What material am I cutting?

What operation am I performing (roughing, finishing, drilling)?

What level of heat and wear will the tool face?

Do I need shock resistance (for interrupted cuts)?

What surface finish do I expect?

最后的想法

Tungsten carbide tools are powerful—but only if you choose the right grade for your application.

By understanding grain size, binder content, and coatings, you can unlock longer tool life, smoother finishes, and faster machining.

Don’t just buy tools—match them to your needs.

如果您想了解任何公司的更多详细信息,请随时 联系我们.