In heavy industries, decision-makers often face one key challenge: selecting the right material for parts that must withstand constant wear, heat, or pressure.

Materials like hardened steel, ceramics, Stellite, and composites are widely used, but tungsten carbide often stands out.

Knowing when to choose tungsten carbide over other high-wear materials can help save costs, improve productivity, and extend equipment life.

This article explains the performance factors, compares tungsten carbide with alternatives, and highlights real-world scenarios where carbide is the best choice.

硬度和耐磨性

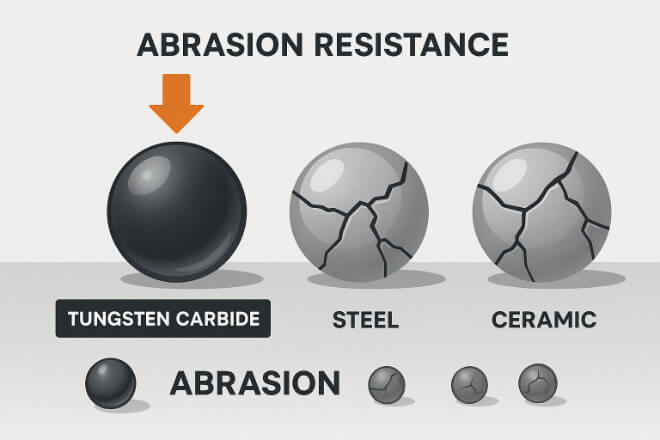

The primary reason companies pick tungsten carbide is its exceptional 硬度。

With a hardness rating close to diamond (around 1600–2000 HV on the Vickers scale), carbide resists abrasion much better than hardened steel or Stellite.

Steel wears down faster under abrasive loads.

Ceramics are hard but brittle.

Carbide provides the right balance of extreme hardness and 韧性, making it perfect for cutting, grinding, and drilling applications.

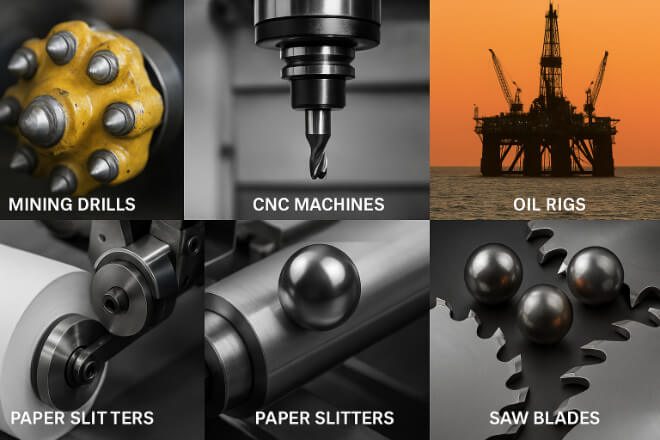

Industries like 矿业, 石油和天然气, and machining choose tungsten carbide when components must run under constant friction and still deliver consistent performance.

Heat and Pressure Resistance

Many wear materials lose strength at high temperatures. Tungsten carbide, however, keeps its hardness and structural stability even above 1000°C.

In high-speed machining, 硬质合金刀具 maintain sharpness far longer than steel.

In oil drilling or 航天, parts exposed to heat and pressure often need carbide’s stability.

If your application demands performance under both heat and load, carbide is usually a smarter investment than steel or ceramics.

耐腐蚀和耐化学性

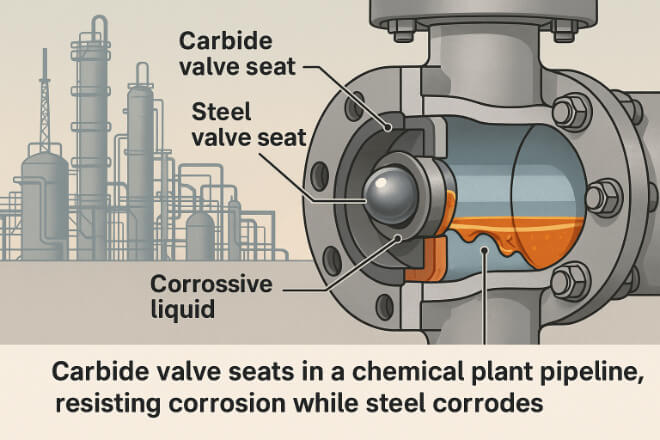

Corrosion is another factor. Steel corrodes easily, even stainless versions under extreme chemical exposure. Ceramics resist corrosion but cannot handle shock.

Tungsten carbide resists wear from acidic or alkaline environments, especially when combined with coatings.

This makes it ideal for pumps, valves, and seal rings in chemical plants, offshore rigs, or refineries.

Comparing Cost and Lifetime Value

One reason some decision-makers hesitate is carbide’s higher upfront cost.

Steel or other alloys are cheaper to buy. But cost-per-hour and cost-per-part often tell a different story.

| 材料 | Cost Level | 耐磨性 | Lifetime Value |

|---|---|---|---|

| 硬化钢 | 低的 | 缓和 | Short lifespan, frequent replacement |

| 陶瓷制品 | 中等的 | High, but brittle | Good in low-shock environments |

| Stellite | 高的 | Good, heat resistant | Strong in aerospace and energy uses |

| 碳化钨 | 高的 | 出色的 | Best balance of wear life and toughness |

In critical industries, the higher upfront cost of tungsten carbide pays off through fewer replacements, less downtime, and lower operational cost.

Application Scenarios Where Carbide Excels

矿业 and Drilling

Bits, hammers, and liners face extreme abrasion. Carbide parts survive much longer than steel.

Metal Cutting and Machining

Carbide cutting tools handle high-speed machining with less wear and better finish.

Downhole tools, valve seats, and chokes benefit from carbide’s heat and corrosion resistance.

Paper and Textile Industry

Blades and slitters made of carbide cut cleaner and last longer under continuous operation.

木工 and Agriculture

Carbide tips on saw blades or plowshares extend tool life under abrasive conditions.

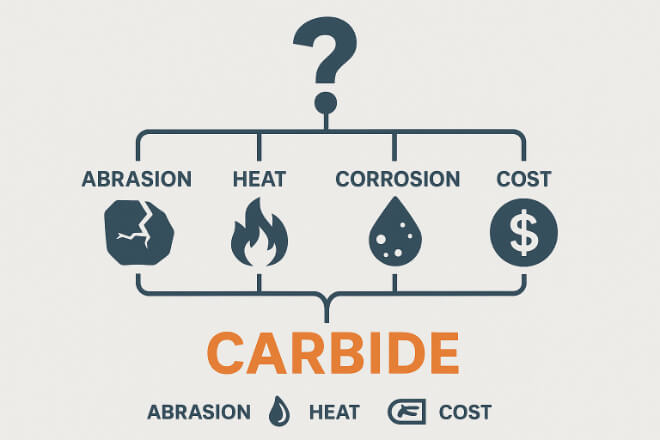

Decision Checklist for Choosing Tungsten Carbide

When evaluating materials for your wear parts, ask:

Will the part face high friction or abrasion?

Will it be used under high heat or pressure?

Is 耐腐蚀性 critical?

What is the cost-per-hour vs cost-per-piece?

Does the application require both hardness and toughness?

If the answer to most is yes, tungsten carbide is the material to choose over steel, ceramics, or other alloys.

最后的想法

Tungsten carbide is not always the cheapest material, but in industries where downtime, wear, and replacement costs add up, it’s often the best choice.

Its combination of hardness, toughness, and chemical resistance makes it a reliable partner in high-stress environments.

For decision-makers, the key is to focus on lifetime value, not just upfront price. In that equation, tungsten carbide usually wins.

如果您想了解任何公司的更多详细信息,请随时 联系我们。