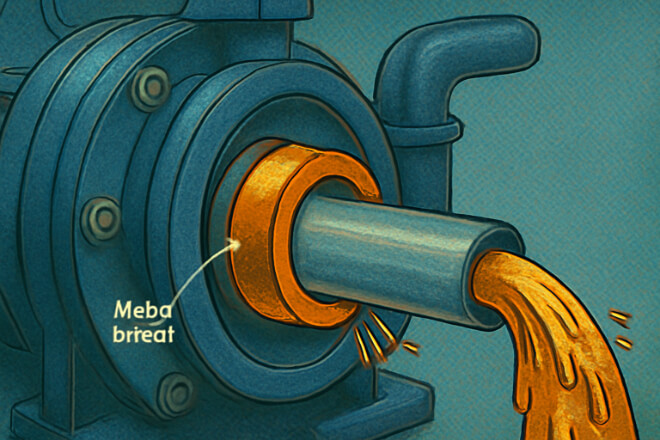

WC-Ni (tungsten carbide–nickel) bujes are widely used in pumps, valves, and rotating equipment because they offer strong resistencia al desgaste and good tenacidad.

But in chloride-rich water, such as seawater or chemical process fluids, corrosion becomes a major concern.

This article explains how WC-Ni bushings behave in chloride environments, what factors drive corrosion, and how to improve their service life in demanding applications.

What Are WC-Ni Bushings?

WC-Ni bushings are a type of tungsten carbide composite, where nickel acts as the binder material, providing toughness and enhancing the material’s ability to withstand mechanical stress.

Tungsten carbide (WC) is extremely hard, offering excellent resistencia al desgaste, while the nickel binder improves the overall toughness and machinability of the material.

Key properties of WC-Ni bushings:

Dureza: WC is one of the hardest materials available, providing high wear resistance.

Tenacidad: The nickel binder helps make the material more resistant to cracking and mechanical failure under high stress.

Resistencia a la corrosión: While WC-Ni bushings offer some level of corrosion resistance, their performance can degrade in highly aggressive environments, especially in the presence of chloride ions.

WC-Ni bushings are commonly used in applications like pumps, valves, and machinery in industries such as mining, chemical processing, and water treatment, where they are exposed to harsh operating conditions.

The Impact of Chloride-Rich Water on Materials

Chloride-rich water, often found in environments such as seawater, chemical plants, and wastewater systems, can accelerate the corrosion process.

Chloride ions are particularly aggressive, and they can break down protective oxide layers on metals and alloys, leading to pitting, cracking, and general material degradation.

How chlorides affect materials:

Pitting corrosion: Chlorides can cause localized corrosion known as pitting, which creates small holes or pits in the material. This can significantly weaken the material over time.

Stress corrosion cracking: When chloride ions are present, they can induce cracks in the material, particularly under tensile stress, which can lead to catastrophic failure.

Decreased material strength: Corrosion can gradually reduce the material’s strength, leading to a higher risk of failure and damage.

Given these challenges, understanding the corrosion behavior of WC-Ni bushings in chloride-rich environments is crucial for improving their performance and lifespan.

Corrosion Resistance of WC-Ni Bushings in Chloride-Rich Water

The corrosion behavior of WC-Ni bushings in chloride-rich water depends on several factors, including the concentration of chloride ions, temperature, pressure, and the mechanical stresses the bushings are exposed to.

While WC-Ni offers some level of Resistencia a la corrosión due to the properties of tungsten carbide, the nickel binder can be susceptible to chloride-induced corrosion.

Factors influencing corrosion resistance:

Nickel content:

Higher nickel content can improve the corrosion resistance of WC-Ni, but the binder still remains more vulnerable to chloride-induced degradation than pure WC.

Acabado superficial:

A smooth surface can help reduce the sites where corrosion can initiate. Rough surfaces may allow chloride ions to accumulate, accelerating corrosion.

Environmental conditions:

Higher temperatures and chloride concentrations increase the rate of corrosion.

The presence of other corrosive agents, such as acids, can also exacerbate the corrosion process.

Protective coatings:

Applying protective coatings or treatments to the WC-Ni bushings can help mitigate the effects of chloride exposure and extend the life of the material.

Studies have shown that while WC-Ni bushings can withstand mild chloride exposure, they are more vulnerable in environments with high chloride concentrations and elevated temperatures.

Enhancing the Corrosion Resistance of WC-Ni Bushings

To improve the performance of WC-Ni bushings in chloride-rich environments, various strategies can be employed, including material enhancements, protective coatings, and environmental control.

Strategies for improving corrosion resistance:

Increased nickel content:

Increasing the amount of nickel in the binder can improve the overall Resistencia a la corrosión of the bushing, though it may also affect the resistencia al desgaste y dureza of the material.

Coatings and surface treatments:

Applying coatings such as ceramic coatings or nickel-based alloys can significantly enhance the corrosion resistance of WC-Ni bushings in chloride-rich environments.

Environmental control:

Minimizing the exposure of WC-Ni bushings to high chloride concentrations and controlling temperature and pressure can help reduce the rate of corrosion.

Corrosion inhibitors:

In some applications, adding corrosion inhibitors to the environment can help protect WC-Ni bushings from chloride-induced corrosion.

By employing these strategies, the lifespan of WC-Ni bushings in corrosive environments can be significantly extended.

Applications of WC-Ni Bushings in Chloride-Rich Water

WC-Ni bushings are used in a variety of applications where they are exposed to chloride-rich water. Common industries include:

Key applications:

Marine and offshore: In seawater pumps and valves, WC-Ni bushings must withstand the harsh effects of saltwater and chloride ions.

Chemical processing: In systems handling corrosive chemicals and wastewater, WC-Ni bushings are exposed to chloride-rich solutions that can accelerate corrosion.

Water treatment: In water treatment plants, pumps and valves often operate in environments where chloride ions are present, requiring corrosion-resistant materials like WC-Ni.

Minería: Mining operations, especially those involving slurry pumps or materials with high chloride concentrations, benefit from the durability of WC-Ni bushings.

In each of these applications, the key is to ensure that the WC-Ni bushings are properly selected, maintained, and protected from corrosion to ensure optimal performance.

Conclusión

The corrosion behavior of WC-Ni bushings in chloride-rich water is a critical factor to consider when selecting materials for pumps, valves, and other machinery in corrosive environments.

While WC-Ni offers good corrosion resistance, it can still be susceptible to chloride-induced degradation under harsh conditions.

By understanding the factors that influence corrosion and implementing strategies such as increased nickel content, protective coatings, and environmental control, the longevity and performance of WC-Ni bushings can be significantly enhanced.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.