Tungsten carbide bushings are known for their outstanding dureza, resistencia al desgaste, and ability to handle extreme conditions.

However, even these durable materials can benefit from additional surface treatments.

DLC (Diamond-Like Carbon) and TiN (Titanium Nitride) coatings are commonly applied to tungsten carbide bushings to improve their performance by reducing friction and enhancing wear resistance.

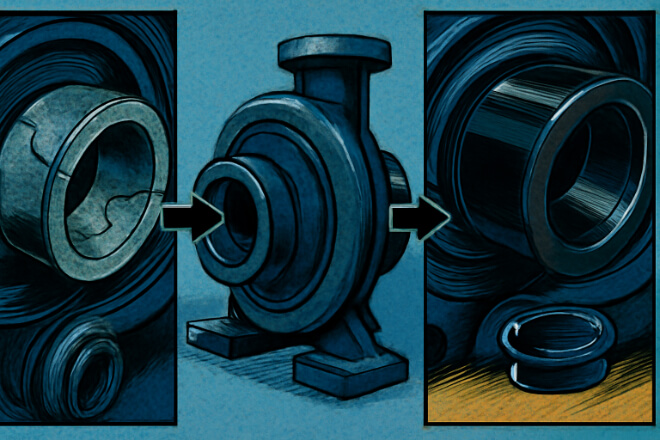

In this blog, we will explore how these coatings work, their benefits in various applications.

And why they make sense for industries looking to extend the life and efficiency of their pumps, valves, and other high-performance components.

What Are DLC and TiN Coatings?

Both DLC (Diamond-Like Carbon) and TiN (Titanium Nitride) coatings are applied to the surface of tungsten carbide bushings to enhance their properties.

These coatings provide additional protection against wear, friction, and corrosion, making the bushings more suitable for demanding applications.

1). DLC Coating:

DLC coatings are a thin layer of carbon-based material that mimics the properties of diamond.

The coating has high dureza, low friction, and excellent resistencia al desgaste, making it ideal for high-speed, high-stress applications.

2). TiN Coating:

TiN is a ceramic coating made from titanium and nitrogen. It is known for its hardness, wear resistance, and excellent corrosion protection.

TiN coatings also provide a smooth surface, which helps to reduce friction in mechanical systems.

Both coatings are widely used in industries such as manufacturing, automotor, petróleo y gas, y minería, where friction and wear are constant concerns.

The Role of Friction and Wear in Pump and Valve Systems

In applications involving pumps, valves, or any rotating machinery, friction and wear are major factors that affect performance and longevity.

Over time, friction between moving parts leads to increased wear, reduced efficiency, and higher maintenance costs.

The impact of friction and wear includes:

Increased energy consumption: High friction leads to more energy being required to maintain system performance.

Shortened equipment lifespan: Wear on components can lead to failure and downtime.

Decreased reliability: As components wear, the risk of leakage, failure, and system breakdown increases.

Higher maintenance costs: Frequent replacements of worn parts increase operational costs.

Reducing friction and wear is essential for maintaining system efficiency and extending the life of critical components.

How DLC Coatings Improve Friction and Wear Resistance

DLC coatings are well-known for their ability to reduce friction, which helps to improve the overall performance of tungsten carbide bushings.

The coating forms a thin, smooth surface that acts as a barrier to friction, minimizing wear on the underlying material.

1). Key benefits of DLC coatings:

Extremely low friction: DLC coatings reduce friction to near-zero levels, resulting in less wear on both the bushing and the shaft.

Superior dureza: The hardness of DLC is similar to that of diamond, which significantly improves resistencia al desgaste en ambientes abrasivos.

Reduced heat generation: Lower friction reduces the amount of heat generated between the moving parts, improving the efficiency of the system.

Improved chemical resistance: DLC coatings are highly resistant to corrosion, making them ideal for use in aggressive environments, such as pumps handling chemicals or high-salinity fluids.

2). Applications of DLC Coated Bushings:

High-speed pumps: Where friction reduction is critical for maintaining speed and efficiency.

Valves: Especially in systems exposed to corrosive or abrasive fluids.

Hydraulic systems: Where the low-friction surface reduces wear and tear, ensuring longer service life.

How TiN Coatings Improve Friction and Wear Resistance

TiN coatings are also effective in enhancing the friction and wear properties of tungsten carbide bushings.

TiN provides a hard, smooth surface that helps reduce friction while also offering excellent protection against wear and corrosion.

1). Key benefits of TiN coatings:

Alto resistencia al desgaste: TiN coatings significantly improve the wear resistance of tungsten carbide bushings, especially in abrasive environments.

Low friction: The smoothness of the TiN coating reduces the friction between moving parts, resulting in higher efficiency and less wear.

Resistencia a la corrosión: TiN coatings provide an excellent barrier against corrosion, making them ideal for pumps and valves handling corrosive fluids.

Improved durability: The coating helps extend the service life of bushings by providing a hard, wear-resistant surface.

2). Applications of TiN Coated Bushings:

Chemical processing: TiN-coated bushings are well-suited for pumps handling corrosive chemicals or acids.

Petróleo y gas: TiN coatings offer protection against the harsh conditions in oil and gas pipelines and pumping systems.

Heavy machinery: Where the bushings are exposed to high stress and abrasive conditions, TiN coatings help improve longevity.

DLC vs. TiN Coatings: Which Is Right for Your Application?

Both DLC and TiN coatings provide significant benefits in reducing friction and wear, but they have different characteristics that make them suitable for specific applications.

Binderless Tungsten Carbide Bushing Coating Comparison Table

| Characteristic | DLC Coating | TiN Coating |

|---|---|---|

| Resistencia al desgaste | Muy alto | Alto |

| Friction Reduction | Extremely Low | Bajo |

| Resistencia a la corrosión | Alto | Muy alto |

| Dureza | Extremely High | Alto |

| Mejor para | High-speed, high-friction applications | Corrosive, chemical, and high-wear environments |

When to Choose DLC or TiN Coated Tungsten Carbide Bushings

Both coatings offer advantages, but the choice between DLC and TiN should be based on the specific needs of the application.

1). Choose DLC Coating if:

Very low friction is required for high-speed or precision applications.

The pump or valve will operate in abrasive environments with minimal chemical exposure.

Extremo dureza is necessary for applications with constant friction and wear.

2). Choose TiN Coating if:

The pump or valve will be exposed to highly corrosive fluids like acids or saline solutions.

You need a balance between resistencia al desgaste y Resistencia a la corrosión.

The application involves heavy-duty or high-pressure systems that are also exposed to abrasive materials.

Conclusión

DLC and TiN coated tungsten carbide bushings are both highly effective in reducing friction and wear in industrial applications.

The decision to choose one over the other should depend on the specific needs of your system, including factors like corrosion resistance, wear conditions, and the nature of the fluids being processed.

By selecting the right coating for your bushings, you can improve performance, reduce downtime, and extend the lifespan of your equipment.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.