タングステンカーバイド切削工具の交換時期の兆候

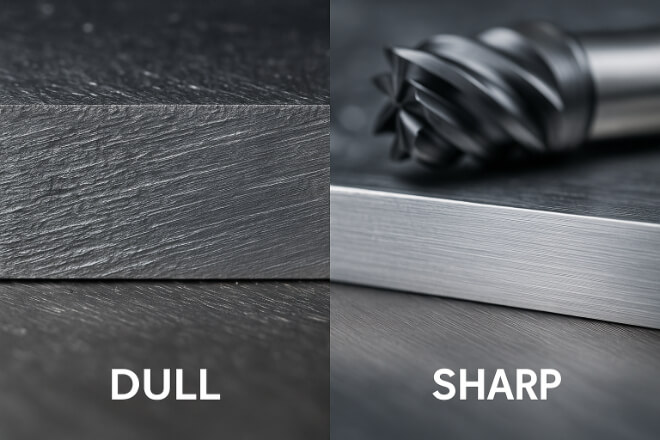

タングステンカーバイド切削工具は、非常に頑丈で長寿命であることで知られています。しかし、他の工具と同様に、いずれ摩耗します。鈍くなったり損傷した工具を使用すると、部品が損傷したり、機械の速度が低下したり、さらにはより深刻な問題を引き起こす可能性があります。工場を管理したり、生産を円滑に進める責任を負っている場合、摩耗した工具をいつ交換すべきかを把握することは非常に重要です。このガイドでは、タングステンカーバイド切削工具の交換時期を示す明確な兆候と、適切なタイミングで交換することでコストを節約できる理由について詳しく説明します。1. 表面仕上げが粗く見える 部品の表面が粗く見えたり、凹凸が見られるようになったら、切削工具の不具合である可能性があります。[…]

炭化タングステン切削工具において適切なサプライヤーを選ぶことが重要な理由

精密機械加工や工業製造の世界では、タングステンカーバイド切削工具が重要な役割を果たしています。これらの工具は、その硬度、耐摩耗性、そして難削材の高速切削能力で知られています。しかし、多くの意思決定者が見落としている重要な要素が1つあります。それは、工具のサプライヤーです。タングステンカーバイド切削工具の適切なサプライヤーを選ぶことは、コストだけでなく、一貫性、性能、信頼性、そして長期的な価値も考慮する必要があります。最高級の材料から作られた高品質の工具は、それを支える企業の質に左右されます。このガイドでは、サプライヤーが工具自体と同じくらい重要である理由を説明します。また、実用的な[…]

炭化タングステン切削工具のコストに影響を与える要因

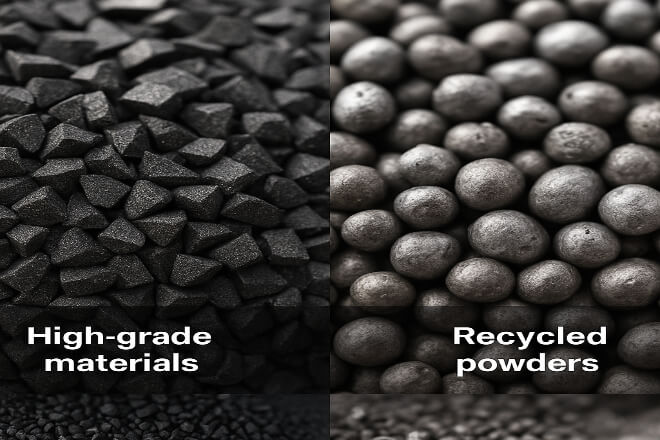

タングステンカーバイド切削工具は、自動車産業や航空宇宙産業から金型製造や一般的な機械加工に至るまで、多くの産業に不可欠な存在です。これらの工具は、その強靭性、耐熱性、そして長寿命で知られています。しかし、購買部門や意思決定者からよく寄せられる質問の一つは、「なぜタングステンカーバイド工具はそれほど高価なのか?」ということです。これらの工具の価格を理解するには、単に材質を見るだけでは十分ではありません。この記事では、タングステンカーバイド切削工具のコストに影響を与える主要な要因を解説します。これにより、より賢明な購入決定を下し、工具投資を最適化することができます。1. 原材料の品質 最も大きなコスト要因の一つは、切削工具に使用される原材料の品質です。[…]

炭化タングステン切削工具に関するよくある誤解を解明

タングステンカーバイド切削工具は、航空宇宙、自動車、一般製造業などの業界で広く使用されています。その強靭性、精度、そして硬質材料の切削能力で知られています。しかしながら、これらの工具の仕組み、耐用年数、そして価格については、依然として多くの誤解が存在します。こうした誤解は、誤った購入決定や効率向上の機会損失につながることがよくあります。この記事では、タングステンカーバイド切削工具に関する最も一般的な誤解を解き明かします。現場監督、購買管理者、あるいは上級管理職の方であっても、このガイドはより良い選択を行い、よくある落とし穴を回避するのに役立ちます。誤解1:タングステンカーバイド工具は高価すぎる 真実:[…]

炭化タングステン切削工具で工具摩耗を減らす方法

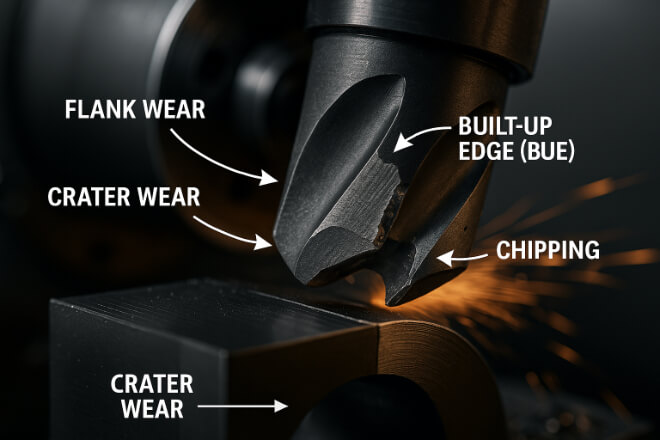

タングステンカーバイド切削工具は、その強度、精度、そして長寿命から、多くの業界で信頼されています。しかし、最も頑丈な工具でさえ、時間の経過とともに摩耗します。機械加工や製造業の意思決定者にとって、工具の摩耗を抑えることは単なる技術的な課題ではなく、賢明なビジネス戦略です。摩耗を抑えることは、コスト削減、生産性向上、そして中断の減少につながります。この記事では、タングステンカーバイド切削工具を用いて工具の摩耗を抑える最適な方法を説明します。航空宇宙、自動車、医療機器製造、あるいは一般的な機械加工など、どのような業界でも、これらのヒントは、チームがより良い意思決定を行い、よりスマートな切削を行い、生産性を向上させるのに役立ちます。1. 工具摩耗の原因を理解する 工具摩耗を抑える前に、[…]

タングステンカーバイドによる精密切削:ベストプラクティスとヒント

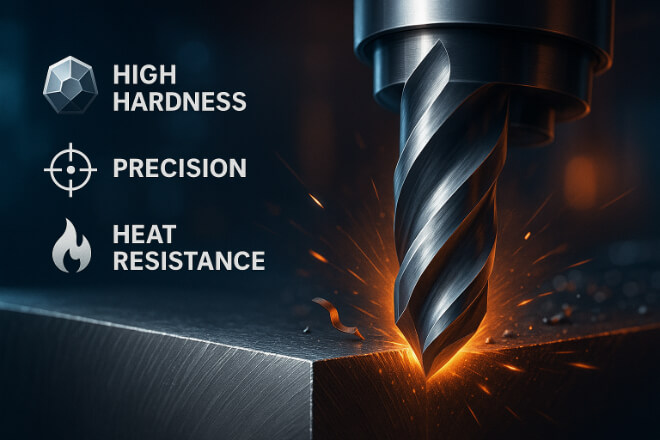

機械加工において、きれいで正確な切削を実現するには、タングステンカーバイド工具が最適な選択肢となることがよくあります。高速度鋼よりも硬く、耐熱性が高く、高速アプリケーションで優れた性能を発揮します。しかし、超硬工具を持っているだけでは十分ではありません。正しい使い方も重要です。このガイドでは、タングステンカーバイド切削工具を最大限に活用するためのベストプラクティスとヒントをご紹介します。CNC工作機械を運用している場合でも、手作業で切削加工を行っている場合でも、これらのヒントは工具寿命を延ばし、ミスを減らし、より良い結果を得るのに役立ちます。1. タングステンカーバイドが精密切削に最適な理由 タングステンカーバイドは[…]

炭化タングステン切削工具の使用による環境への影響

今日の世界では、人々はこれまで以上に持続可能性を重視しています。個人の選択から産業活動に至るまで、誰もが廃棄物の削減、省エネ、そして地球にとってより良い意思決定に努めています。しかし、機械加工や製造について語るとき、環境への影響はしばしば見落とされがちです。そこでタングステンカーバイド切削工具が登場します。これらの工具は非常に硬く長寿命であることで知られていますが、それは環境にどのような影響を与えるのでしょうか?廃棄物の削減に役立っているのでしょうか?それとも、環境負荷の高い工業製品の一つに過ぎないのでしょうか?タングステンカーバイド切削工具の使用が実際に環境に与える影響、そしてなぜそれがあなたの生活におけるより環境に優しい選択肢の一つとなるのかを探ってみましょう。[…]

高品質の炭化タングステン切削工具の見分け方

CNC工作機械やその他の高精度アプリケーションを扱う場合、工具の選択が結果を左右します。タングステンカーバイド切削工具は、強度、耐久性、高速加工性に優れているため人気があります。しかし、すべての超硬工具が同じ品質というわけではありません。このガイドでは、タングステンカーバイド切削工具が本当に高品質かどうかを判断する方法を説明します。初めて工具を購入する方でも、性能の悪い輸入品を避けたい方でも、この記事はより賢い選択に役立ちます。1. タングステンカーバイドの特別な点とは?タングステンカーバイドは、タングステンと炭素原子の混合物から作られた超硬質材料です。炭素よりも硬いです[…]

炭化タングステン切削工具の性能向上におけるコーティングの役割

タングステンカーバイド切削工具は、その強度と耐久性で知られています。しかし、どんなに硬い工具でも、過酷な条件下ではすぐに摩耗してしまうことがあります。そこでコーティングが役立ちます。適切なコーティングを施すことで、工具の寿命、切削性能、そして長期的なコスト削減に大きな違いが生まれます。このブログ記事では、様々な種類のコーティングがタングステンカーバイド切削工具の性能向上にどのように役立つかを探ります。CNC工作機械を運営している方でも、単に工具コストの削減を目指している方でも、このガイドはコーティングの重要性を理解するのに役立ちます。1. 超硬切削工具にとってコーティングが重要な理由とは? タングステン […]

炭化タングステン切削工具の一般的な問題と解決策

タングステンカーバイド切削工具は、その硬度と長い工具寿命でよく知られています。CNC加工、航空宇宙、自動車、その他多くの高精度産業で広く使用されています。しかし、これらの耐久性の高い工具であっても、適切に使用またはメンテナンスしないと問題が発生する可能性があります。この記事では、タングステンカーバイド切削工具の使用時に直面する最も一般的な問題を取り上げ、それぞれに対するシンプルで実用的な解決策を紹介します。機械工、工場経営者、生産エンジニアなど、どのような立場の人でも、これらの問題を理解することで、工具寿命を延ばし、コストのかかるダウンタイムを回避することができます。1. 工具の早期摩耗問題:タングステンカーバイドは高い耐摩耗性を備えていますが、不適切な使用方法によって工具が急速に摩耗してしまうことがあります。[…]