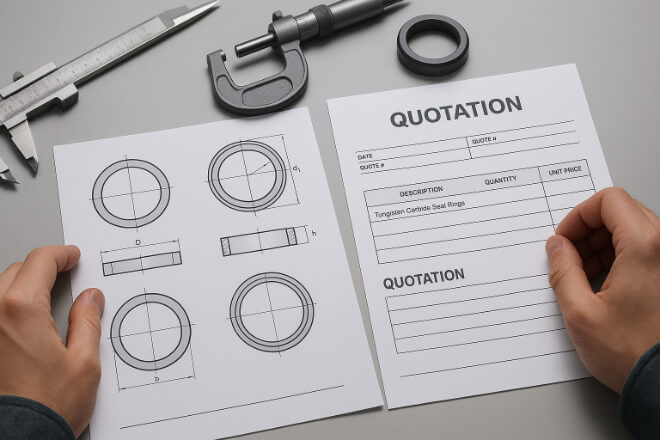

When preparing a Request for Quotation (RFQ) for custom 超硬シールリング, many decision-makers focus only on price and delivery time.

However, the real value of a quote depends on the accuracy of technical details you provide.

Missing or unclear information about dimensions, tolerances, and surface finish can lead to production delays, design mismatches, or costly rework.

This guide offers a practical checklist to help engineering and procurement teams send complete and clear RFQs for tungsten carbide seal rings.

It will help you communicate your needs precisely and ensure you receive accurate quotations from manufacturers.

Understanding the Role of Carbide Seal Rings

Tungsten carbide seal rings are critical components in pumps, compressors, and rotating equipment.

They provide sealing performance, 耐摩耗性, and corrosion protection under harsh conditions.

These rings are often used in 石油とガス, chemical, and mechanical seal assemblies, where reliability and precision are vital.

Because every application is different, many companies require custom carbide seal rings with specific material grades, surface finishes, and geometrical tolerances.

That’s why a detailed RFQ is the foundation of a successful project.

Why a Detailed RFQ Matters

A clear and well-prepared RFQ checklist helps both you and your supplier.

It reduces the number of clarification emails and design revisions.

It ensures that the quotation you receive reflects the actual cost and lead time.

It allows your supplier to choose the most efficient carbide grade and machining process.

In short, a complete RFQ saves time, prevents misunderstandings, and builds trust between buyer and manufacturer.

Key Details to Include in Your RFQ

When sending your RFQ for custom 超硬シールリング, make sure you include at least the following information:

1). Basic Information

Part name and quantity

Application (e.g., mechanical seal, pump, compressor)

Operating conditions (temperature, pressure, media type)

2). Material and Grade

Specify the tungsten carbide grade if known.

If you’re not sure, describe the working environment (abrasive, corrosive, or high temperature).

The supplier can then recommend a suitable grade.

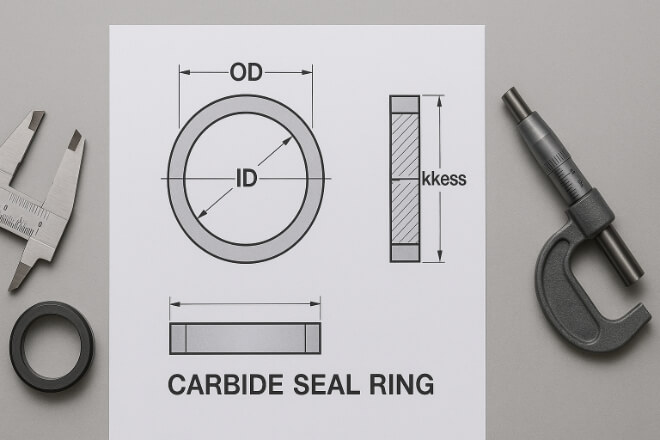

3). Dimensions

Provide full dimensional data. For seal rings, the key parameters usually include:

Outer Diameter (OD)

Inner Diameter (ID)

Thickness or Height

Chamfer or radius details

You can describe them in a drawing or table. Here’s a simple example:

| パラメータ | Symbol | ユニット | 価値 |

|---|---|---|---|

| 外径 | OD | んん | 45.00 ±0.02 |

| Inner Diameter | ID | んん | 30.00 ±0.02 |

| Thickness | T | んん | 8.00 ±0.01 |

Including such a table helps the supplier quote faster and avoid interpretation errors.

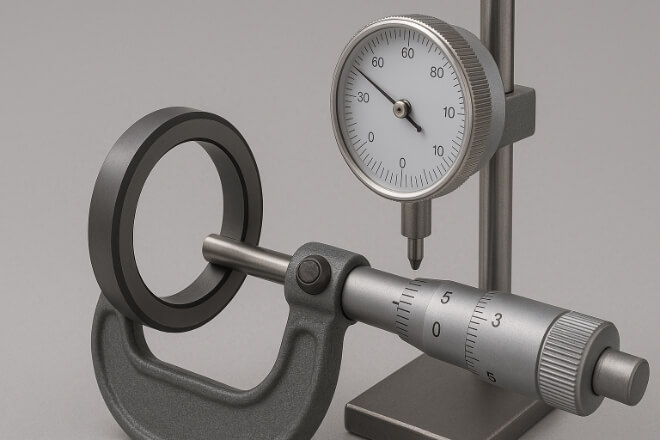

Specifying Tolerances

Tolerances define how much variation is acceptable in your ring’s dimensions.

For precision sealing components, tolerances can directly affect leakage rates and rotational stability.

Common tolerance types include:

Dimensional tolerances (e.g., ±0.01 mm)

Flatness and roundness

Concentricity

Surface parallelism

If your ring must fit tightly with another rotating component, always specify mating part tolerances too.

If not specified, manufacturers will apply their standard tolerance range, which may not meet your sealing requirements.

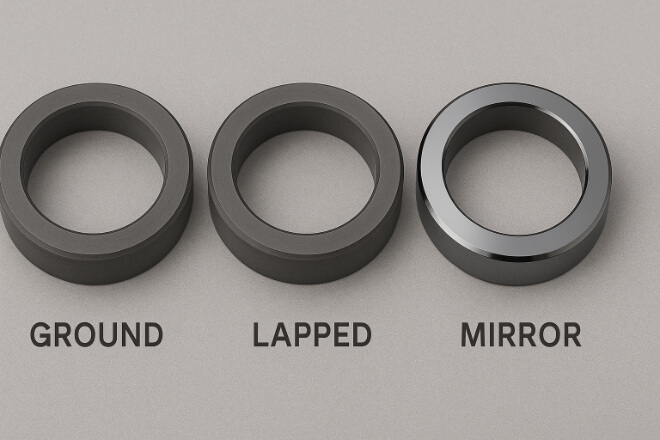

Choosing the Right Surface Finish

Surface finish is critical for the friction performance and sealing efficiency of carbide rings.

A smoother surface reduces wear and prevents leakage during long-term operation.

Common finish options include:

Ground finish (Ra 0.4–0.8 μm)

Lapped finish (Ra 0.1–0.2 μm)

Mirror finish (Ra ≤ 0.05 μm)

The required finish depends on the ring’s application:

Stationary rings in mechanical seals often need a mirror finish.

Rotating rings may perform well with a fine ground finish.

If your application involves high pressure, abrasive media, or corrosive fluids, mention this clearly.

It helps the supplier select proper lapping and polishing processes.

Additional Points for a Complete RFQ

Besides the main technical details, don’t forget these items:

Coating or treatment (e.g., nickel plating, diamond coating)

Quantity and delivery schedule

Drawing files (2D/3D format preferred)

Packaging requirements (to protect precision surfaces)

Quality certification or inspection report requirements

Adding these points ensures your RFQ checklist is complete and professional.

避けるべきよくある間違い

Even experienced buyers can make small mistakes that cause big delays. Watch out for:

Sending only a photo without a technical drawing

Not clarifying working conditions (temperature, medium)

Forgetting to specify tolerances or surface finish

Requesting “the best quality” without describing functional requirements

A professional supplier can help you correct missing details, but it’s always better to send clear specifications from the start.

Benefits of a Well-Structured RFQ

When your RFQ for carbide seal rings is complete and clear:

You get faster and more accurate quotations

Manufacturers can optimize material usage and machining time

The delivered rings fit perfectly with your assemblies

You build a long-term, trusted relationship with your supplier

In other words, a good RFQ isn’t just a request — it’s the foundation of successful cooperation.

結論

Preparing an RFQ for custom tungsten carbide seal rings doesn’t have to be complicated.

By focusing on the three core areas — dimensions, tolerances, and surface finish — you can avoid confusion and ensure precision from the first quotation.

Before sending your next RFQ, review this checklist. A few extra minutes spent on documentation can save weeks of communication later — and guarantee that your carbide seal rings perform exactly as expected in your critical applications.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。