Choosing the right carbide seal face under API-682 is less about ticking a box and more about avoiding surprises in the field.

A choice that looks good on paper can perform poorly if the flush is wrong, if there’s vibration, or if the fluid chemistry is harsher than expected.

This write-up is for engineers and decision-makers who want practical guidance — not theory — so you can pick seal faces that keep pumps running and maintenance predictable.

Why API-682 Matters for Carbide Face Selection

API-682 gives a consistent way to specify seal types, support plans, and material groups.

It makes it easier to compare vendors and to set expectations for reliability. But the standard is a framework, not a substitute for local experience.

Use API-682 to frame the decision, then apply site data — fluid tests, vibration records, downtime costs — to pick the right carbide grade and face pair.

Types of Carbide Seal Faces

Carbide faces are primarily tungsten carbide (WC) and silicon carbide (SiC). Each has strengths and limits — WC is tougher; SiC is more chemically inert.

| 材料 | Key Strengths | 一般的な用途 |

|---|---|---|

| Tungsten Carbide (WC) | High toughness; resists edge chipping and impact | Hydrocarbons, lubricated services, vibration-prone pumps |

| Silicon Carbide (SiC) | Excellent chemical resistance; low friction | Corrosive fluids, high-temp, abrasive slurries |

Often a hybrid pairing (WC vs SiC) is the practical compromise: 強靭さ on one side, corrosion resistance on the other.

Practical Criteria (What You Check on Site)

When I review a seal spec, I run through these questions — simple, but they catch most bad matches.

Fluid chemistry: PH, chlorides, oxidizers. If you have chlorides or strong alkali/acid, SiC or nickel-bonded WC is safer.

Abrasives or solids: Coarse particles vs fine slurry — WC handles impact better; SiC handles fine abrasion well.

Temperature swings: Rapid changes cause thermal shock. WC generally tolerates shock better than SiC.

Shaft condition and vibration: High runout or poor alignment → avoid brittle faces.

Flush plan: What API plan is used? Plan choice changes face cooling and contamination risk.

Spare policy & cost: Can you live with longer life and higher cost, or do you need a low-cost replaceable option?

Trade-offs: Cost, Life, and Risk

Make no mistake: the cheapest face today can cost you twice as much in lost production. Below is a practical comparison.

| 要素 | トイレ | SiC |

|---|---|---|

| Initial cost | より低い | より高い |

| Impact resistance | 良い | Moderate (brittle) |

| Chemical resistance | Good (binders may leach in aggressive fluids) | 素晴らしい |

| Thermal robustness | Better for shock | Sensitive to rapid change |

| Typical in-field life (example) | 3–5 years (varies) | 4–7 years (in corrosive conditions) |

Decision rule I use: choose the material that minimizes total cost of ownership, not just unit price.

API-682 Face Combinations I Rely On

API-682 groups face types logically. My go-to pairs in the field:

| Service | Recommended Pair | なぜ |

|---|---|---|

| Clean hydrocarbon | WC vs SiC | Toughness + low friction |

| Abrasive slurry | WC vs WC | Best for impact and large particles |

| Corrosive / caustic | SiC vs SiC or Ni-bonded WC vs SiC | Chemical inertness |

Note: Pairing must consider face finish, tolerance, and balance ratio. API-682 push is to think of the whole seal system — face material is one variable among many.

Common Mistakes (and How to Avoid Them)

Below are recurring errors on projects and the operational consequences.

| Mistake | Consequence |

|---|---|

| Specifying standard WC without fluid check | Binder leaching, pitting, shortened life |

| Neglecting flush plan capacity | Overheat, thermal cracking on faces |

| Choosing SiC on a high-runout pump | Edge chipping and premature failure |

| No spare standardization | Delays and wrong replacements |

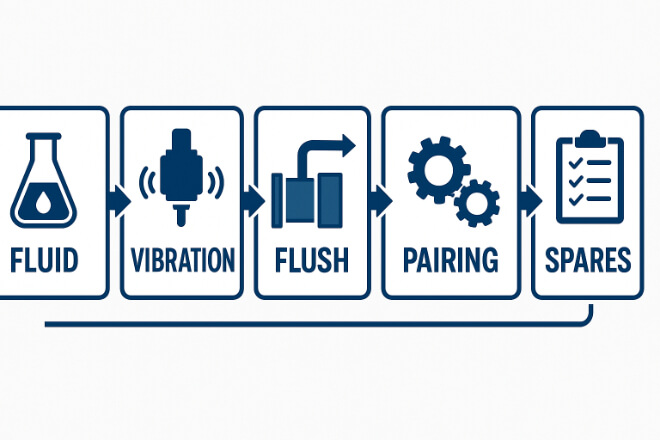

Fix: Run a short site survey before final spec — fluid sample, vibration scan, and spare policy check.

Quick Selection Checklist (Field-Ready)

Fluid test: pH, chlorides, solids.

Measure shaft runout and vibration.

Confirm API flush plan and actual flow capability.

Decide on face pairing and coating (e.g., DLC, CrN).

Check vendor tolerances for flatness and Ra.

Review spare parts strategy and lead times.

結論

API-682 gives you the map, but you still need to drive. In practice, pick the carbide faces that match your fluid, your temperatures, and your machine condition.

If vibration and runout are common, pick toughness first (WC or Ni-bonded WC).

If the fluid is aggressive, prioritize chemical resistance (SiC or coated faces). If the process is mixed, hybrid pairs almost always win.

Small steps — a quick fluid check, a runout reading, and confirming your flush plan capacity — prevent most seal problems.

Treat material selection as a site decision, not a catalog choice. Do that, and the seals will stop being the cause of your longest outages.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。