炭化タングステンは、今日の鉱業や建設業で使用されている最も重要な材料の一つです。強度と耐久性に優れ、過酷な作業環境に最適です。これらの業界の企業は、岩、コンクリート、その他の硬い材料を、すぐに破損したり摩耗したりすることなく切断できる工具を必要としています。そのため、炭化タングステン製の切削工具は、多くの専門家にとって第一選択肢となっています。

タングステンカーバイドとは何ですか?

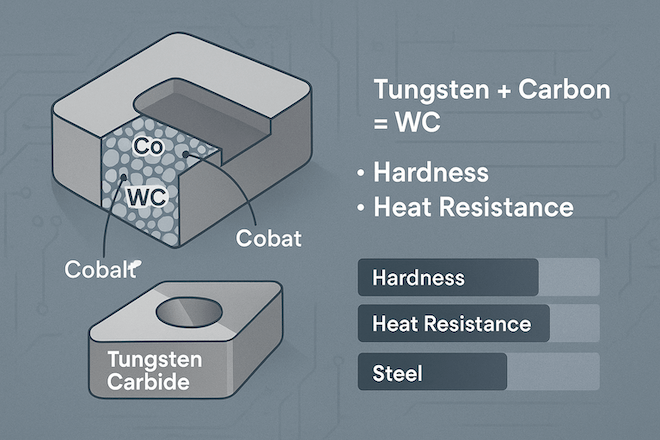

炭化タングステン(炭化タングステン)は、タングステンと炭素を結合させた硬質金属です。鋼鉄よりもはるかに硬く、長時間使用しても鋭い切れ味を保ちます。炭化タングステンで作られた工具は、摩耗、熱、圧力に強く、鉱業や建設業に最適です。

鉱業と建設業において超硬工具が重要な理由

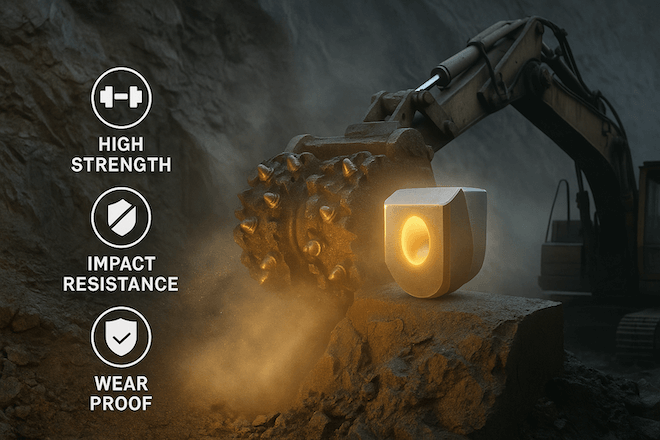

鉱業と建設業機械は非常に過酷で過酷な環境で稼働します。工具は岩や鉄筋コンクリートなどの硬い表面を掘削、切断、研磨する必要があります。工具が破損すると、作業の遅延やコストの増加につながります。

タングステンカーバイド工具は、このような問題を回避するのに役立ちます。

通常の鋼製工具よりも強力

ひび割れや摩耗に対する耐性が向上

高速作業が可能

深穴あけや重切削に最適

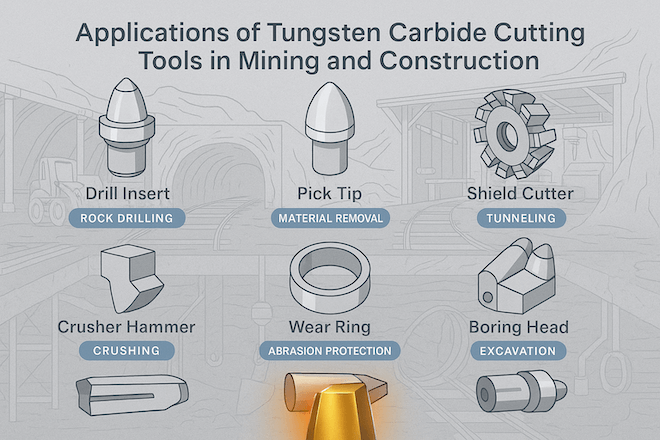

鉱業における主な用途

炭化タングステン工具は多くの採掘プロセスで使用されています。

ドリルビットインサート:地下深くの硬い岩石を破砕するために

切削ピック:石炭または軟岩の採掘用

摩耗部品:摩耗にさらされる工具用

トンネル掘削ツール:トンネル掘削機で使用される

破砕機部品:破砕装置の寿命を延ばす

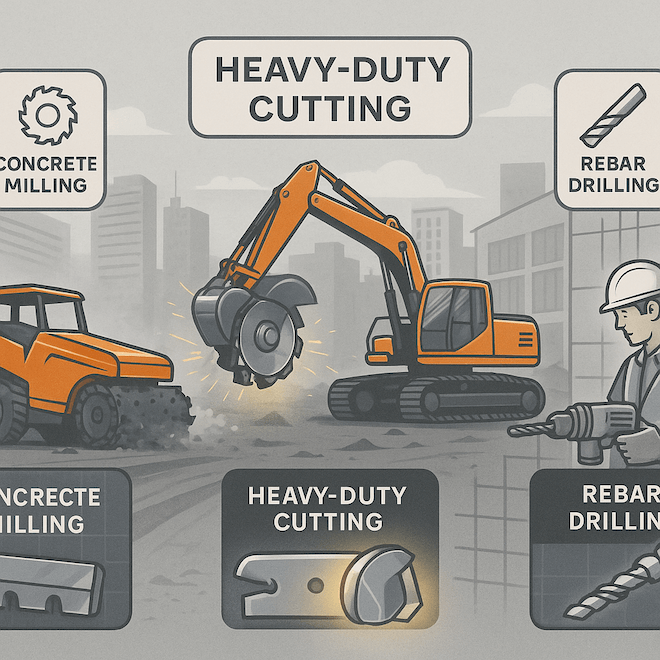

建設における主な用途

建設業界では、超硬工具は次のような材料の切断、成形、研磨に使用されます。

コンクリートと石

アスファルトとレンガ

鉄筋

道路工事および舗装工事

一般的なツールには次のようなものがあります:

超硬チップ付き鋸刃

コンクリートドリルビット

道路切削歯

ノミと解体用ビット

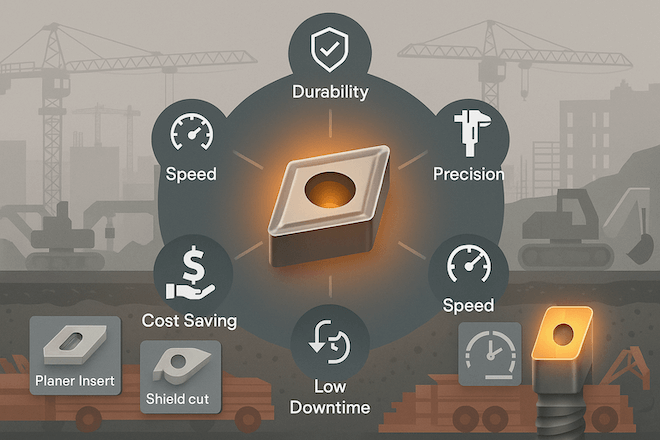

炭化タングステン切削工具の利点

意思決定者にとっての主なメリットは次のとおりです。

工具寿命が長い = 交換コストが低い

パフォーマンスの向上 = ツール交換の削減

切断速度が速いほど、出力が高くなります

正確な結果 = きれいなカットと無駄の削減

ダウンタイムの短縮 = 機械の稼働時間の増加

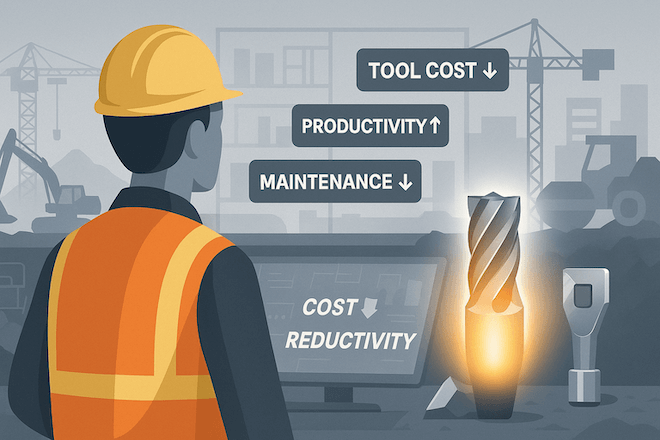

鉱業・建設会社が炭化タングステンを選ぶ理由

超硬工具の使用は企業にとって次のようなメリットをもたらします。

長期的にお金を節約する

機械の稼働時間を長くする

ツールの故障を減らして作業者の安全性を向上

遅延を減らして期限を早く守る

ツールだけの問題ではなく、プロジェクトを時間どおりに予算内で進めることが重要です。

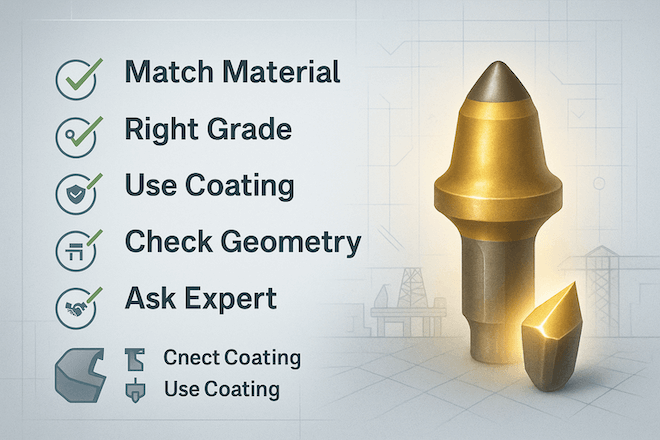

適切な超硬工具を選ぶためのヒント

適切なツールを選ぶことが重要です。以下の点を確認してください。

ツールを材質(岩、コンクリート、金属)に合わせて調整します

耐摩耗性や靭性に適したグレードを選択してください

形状をチェックする – 歯の形状は切削に影響します

高熱作業にはコーティングを使用する

不明な場合は専門家に相談してください

結論:過酷な仕事への賢い投資

炭化タングステン工具は、鉱業や建設業にとって賢明な選択です。コスト削減、作業速度の向上、工具の摩耗軽減を実現します。道路建設でもトンネル掘削でも、炭化タングステン工具は作業をより速く、より安全に、そしてより良い結果で完了させるのに役立ちます。