Tungsten carbide (WC) bushings are highly durable components used in many industrial applications.

They are designed to withstand high pressures, speeds, and harsh conditions. However, they can still experience damage, especially from the mating surface or counterface.

Understanding the different damage modes that can occur between the bushing and its counterface is crucial for preventing premature failure.

This article will explain the common counterface damage modes and how to prevent them.

What Is Counterface Damage in Tungsten Carbide Bushings?

Counterface damage occurs when the mating surface, such as the shaft or housing, wears down and interacts negatively with the tungsten carbide bushing.

These interactions can lead to surface degradation, wear, and sometimes catastrophic failure if not properly managed.

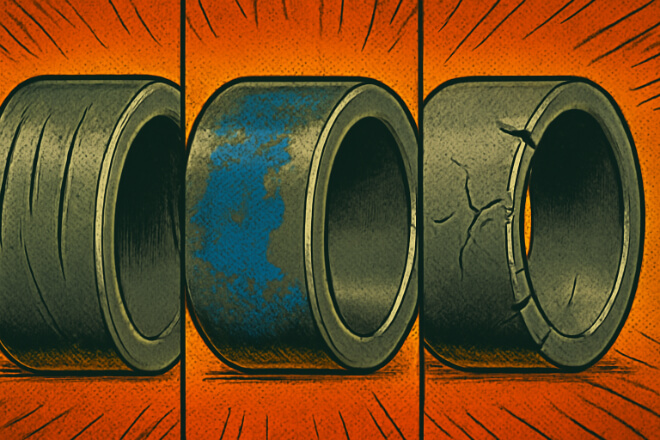

Types of Counterface Damage:

Abrasion: Occurs when hard particles or rough surfaces grind against the bushing.

Adhesion: Happens when materials transfer from the counterface to the bushing, causing surface roughness.

Corrosion: Occurs when the counterface or bushing is exposed to harsh chemicals or moisture.

Fatigue: Happens after repeated stress cycles, leading to cracks or fractures in the bushing.

Understanding these damage modes helps in taking preventive measures and improving bushing lifespan.

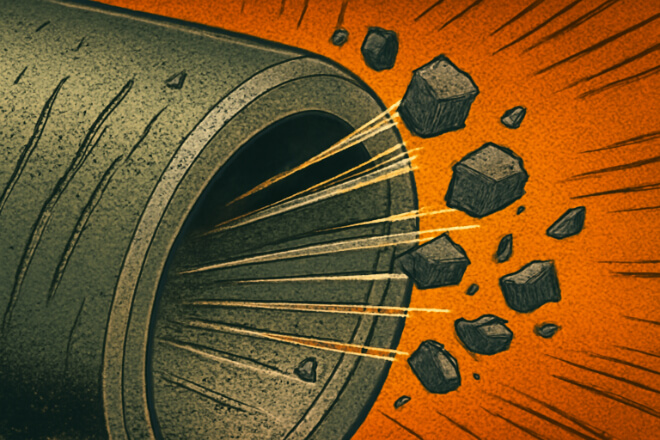

Abrasive Damage: How Roughness and Particles Contribute

Abrasive damage is one of the most common types of counterface damage in tungsten carbide bushings.

It occurs when rough particles or a rough counterface create friction and wear on the bushing surface.

Causes of Abrasive Damage:

Contaminants: Dirt or hard particles that enter the system can scratch the bushing surface.

Rough Counterfaces: A poorly finished shaft or housing with rough surfaces can create constant abrasion.

High-velocity Slurries: In pumps or compressors handling abrasive materials, particles can act like sandpaper on the bushing.

| 粒子サイズ | Wear Type | Impact on WC Bushing |

|---|---|---|

| 大丈夫 (<50 μm) | マイクロアブレーション | Slow wear over time |

| 中(50~150μm) | 耕作 | Grooves and surface damage |

| 大きい(>150 μm) | 切断 | Deep scratches, faster wear |

Adhesive Wear: When Material Transfers Between Surfaces

Adhesion occurs when the mating surface, such as the shaft, leaves material behind on the tungsten carbide bushing.

This can happen when there is too much friction, poor lubrication, or when the surfaces are incompatible.

How Adhesive Wear Happens:

Lack of Lubrication: Insufficient lubrication increases friction, causing material transfer from the counterface to the bushing.

High Load Conditions: Excessive pressure on the bushing can lead to surface bonding between the counterface and the bushing.

Adhesive wear leads to a rough surface and reduces the performance of the bushing.

It can also cause galling, where the bushing surface becomes damaged due to the bonding and scraping of material.

Corrosion Damage: When Chemicals or Moisture Attack the Surface

Corrosion occurs when the tungsten carbide bushing is exposed to harsh chemicals, moisture, or other corrosive agents.

While WC bushings are generally resistant to corrosion, exposure to aggressive fluids can still lead to wear and eventual failure.

Factors That Contribute to Corrosion:

Aggressive Chemicals: High acidity or alkalinity in the fluid can attack the bushing surface.

Water and Moisture: Water exposure can lead to rusting and degradation of the bushing surface over time.

Improper Fluid Selection: Incorrect fluid selection for the operating conditions can accelerate corrosion.

| Corrosive Agent | WCブッシングへの影響 | Preventive Measure |

|---|---|---|

| Acidic Fluids | Surface erosion, weakening | Use corrosion-resistant coatings |

| Alkaline Fluids | Material breakdown | Choose compatible material for fluid type |

| Water | Rust, pitting | Apply moisture-resistant coatings |

Fatigue Damage: Repeated Stress Leading to Cracking

Fatigue occurs after the tungsten carbide bushing has been subjected to repeated loading and unloading cycles.

Over time, this constant stress can lead to microcracks in the bushing, which eventually cause failure.

Causes of Fatigue Damage:

High Cyclic Loads: Frequent changes in load stress can lead to fatigue failure.

Vibration: Constant vibration or shock loading can lead to crack formation.

Misalignment: When the bushing is misaligned, it experiences additional stress, leading to fatigue.

Fatigue damage can be difficult to detect early, as it often starts as tiny cracks that gradually expand.

Best Practices for Preventing Counterface Damage to WC Bushings

Preventing counterface damage is essential to ensure the longevity of tungsten carbide bushings. Here are some best practices:

1). Regular Inspections

Inspect the bushing and counterface regularly to check for signs of wear, cracks, or surface degradation.

2). Improve Lubrication

Ensure that the system is properly lubricated to reduce friction between the bushing and counterface. Use high-quality lubricants suitable for the application.

3). Use Compatible Materials

Ensure that the materials of the bushing and counterface are compatible. Avoid using soft shafts with hard WC bushings to prevent premature wear.

4). Maintain Proper Alignment

Misalignment increases stress on both the bushing and counterface. Regularly check alignment and make adjustments as needed.

5). Use Protective Coatings

Coatings like TiN, DLC, or other surface treatments can help reduce wear and corrosion on both the bushing and counterface.

結論

Counterface damage is a common issue that can significantly reduce the lifespan of tungsten carbide bushings.

Understanding the different types of damage—abrasive wear, adhesive wear, corrosion, and fatigue—is key to preventing premature failure.

By following best practices such as regular inspections, proper lubrication, material compatibility, and alignment, you can extend the life of your WC bushings and ensure smooth operation in harsh conditions.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。