競争の激しい今日の製造業界では、スピードが全てです。企業はダウンタイムと廃棄物を削減しながら、高品質な部品をより速く生産する必要があります。

ここで高速加工 (HSM) が登場します。これは、より高速な切削速度と送り速度を使用して生産性を向上させるプロセスです。

しかし、問題があります。すべてのツールがそのような厳しい条件下で耐えられるわけではないのです。

ここは タングステンカーバイド切削工具 大きな違いを生みます。

これらは組み合わさって 強靭さ, 硬度、耐熱性に優れており、高速加工に最適です。

この記事では、これらのツールがどのように加工の高速化、部品の品質向上、運用コストの削減をサポートするかについて説明します。

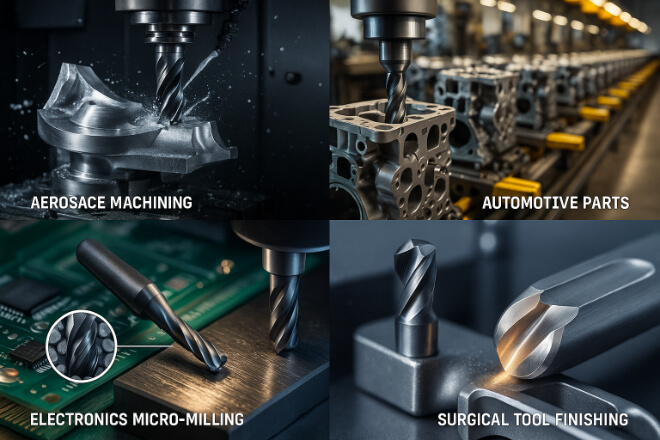

次のような業界に携わっている場合 航空宇宙, 自動車, 型作り、または一般的な CNC 加工については、読み続けてください。

高速加工に優れた工具が必要な理由

高速加工 (HSM) は、作業をより高速に、より正確に、そしてダウンタイムを短縮することを目的としています。

これにより、メーカーは品質を犠牲にすることなく、より短時間でより多くの部品を生産できるようになります。

しかし、すべての工具がHSMの過酷な条件に耐えられるわけではありません。そこでタングステンカーバイド切削工具が活躍します。

タングステンカーバイドは非常に硬く、鋼鉄よりもはるかに硬いです。また、高温にも耐えられるため、高速で切断し、大量の熱を発生させる場合には非常に重要です。

高速加工では、鋭い切れ味を維持し、摩耗に耐え、一貫した結果を出すことができるツールが必要です。

そのため、従来の高速度鋼 (HSS) 工具から超硬工具に切り替えるメーカーが増えています。

炭化タングステンの物理的強度

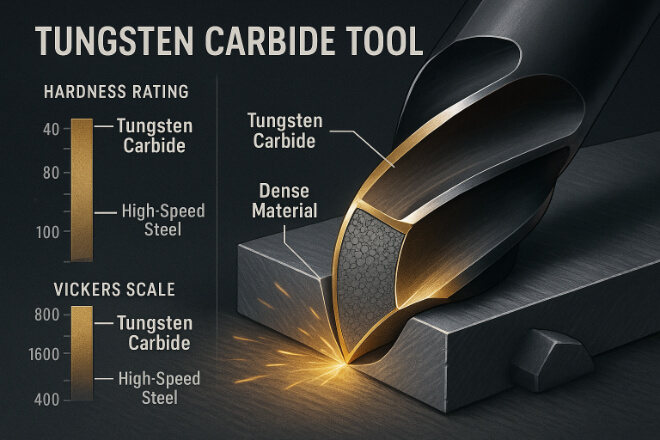

炭化タングステンは、タングステンと炭素原子を結合し、コバルトなどの結合剤と混合することによって作られます。

これにより、信じられないほど硬く密度の高い材料が生まれます。 硬度 通常、ビッカース硬度スケールでは 1600~2400 HV の範囲になりますが、HSS の場合は約 700 HV になります。

この硬さにより、2 つの大きな利点が生まれます。

鋼よりも長く刃先の鋭さを維持

激しい切削時の変形を軽減

ツールの形状と鋭さが維持されるため、ステンレス鋼、チタン、硬化合金などの難しい材料を切断する場合でも、表面仕上げが向上し、精度が向上します。

高速操作の圧力下でも、タングステンカーバイド工具はその形状を維持するため、頻繁な工具交換の必要性が減り、1 回の実行で製造できる部品の数が増えます。

耐熱性:高速加工における重要な要素

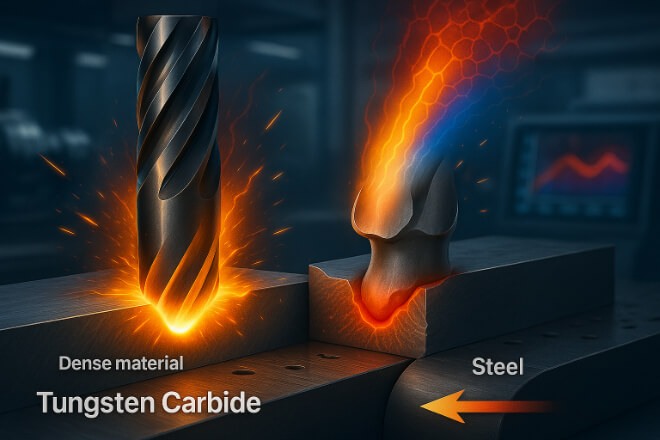

切断速度が上がると、切断領域の温度も上がります。

通常の工具は、このような熱にさらされると柔らかくなったり、形が崩れたり、すぐに摩耗したりすることがあります。しかし、タングステンカーバイドは優れた耐熱性を備えています。

超硬工具はHSS工具の最大4~6倍の切削速度で加工できます。これは以下の理由によります。

硬度を失うことなく高温に耐えることができます

ワークピースへの熱伝導が少ない

赤熱した刃先でも構造が維持される

そのため、ドライカット、高送りフライス加工、硬質材料の仕上げパスなどの高速操作に最適です。

耐摩耗性の向上により工具寿命が延長

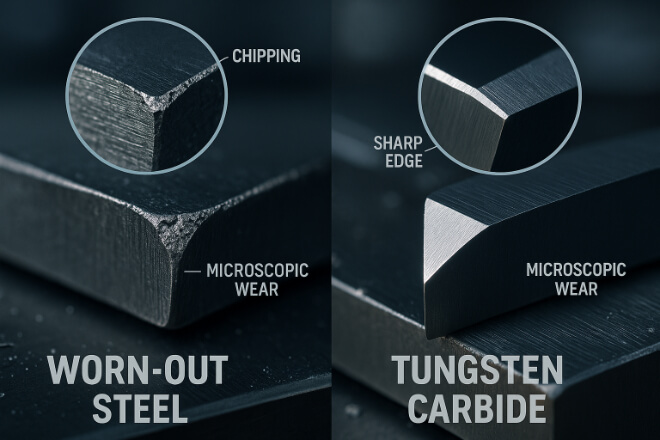

高速加工において、摩耗は大敵です。鈍い工具は仕上がりの悪化、加工速度の低下、そしてダウンタイムの増加につながります。

タングステンカーバイド工具は、他のほとんどの工具材料よりも耐摩耗性に優れています。

炭化物の粒子構造とバインダー含有量は、摩耗、接着、熱疲労などの摩耗メカニズムを遅くするように設計されています。

適切なコーティング(TiAlNやAlTiNなど)により、 耐摩耗性 さらに向上します。

これはつまり:

ツールごとにパーツが増える

頻繁に研ぐ必要がない

ツール交換時のダウンタイムの短縮

工具寿命が長ければ、長期的にはコストも節約できます。超硬工具は初期費用が高くなる場合もありますが、耐久性が高いため、時間が経つにつれて価値が高まります。

HSM戦略とツールジオメトリのマッチング

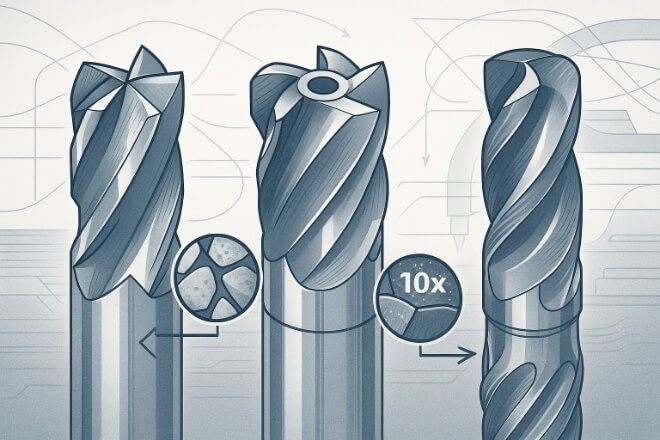

タングステンカーバイド切削工具は、トロコイドフライス加工、動的ツールパス、高送り技術などの高速戦略をサポートする形状で設計できます。

これらのジオメトリには次のものが含まれます。

鋭い刃先で切削力を軽減

切削片排出性を向上させる特殊フルート設計

切削の滑らかさを向上させるために最適化されたすくい角

CNC マシンが高度化するにつれて、ツールの形状がより大きな役割を果たすようになります。

超硬工具は、折れたり欠けたりすることなく、薄くて攻撃的な形状を扱うのに十分な剛性を備えています。

パフォーマンスを向上させるコーティングオプション

適切なコーティングを施すことで、炭化タングステン切削工具の性能をさらに向上させることができます。

コーティングは摩擦を減らし、熱を管理し、工具の表面を摩耗や化学的損傷から保護します。

HSM の一般的なコーティングには次のようなものがあります。

| コーティング | 理想的な用途 | 利点 |

|---|---|---|

| TiAlN | スチール、ステンレス | 耐熱性、酸化防止 |

| アルティン | 硬化鋼 | 優れた耐摩耗性 |

| ダウンロードコンテンツ | アルミニウム、プラスチック | 材料の付着を軽減 |

| CVDダイヤモンド | 複合材料 | 極めて高い硬度、長寿命 |

適切なコーティングを選択することは、特に高速加工のストレス下で工具寿命と切削性能を維持するために重要です。

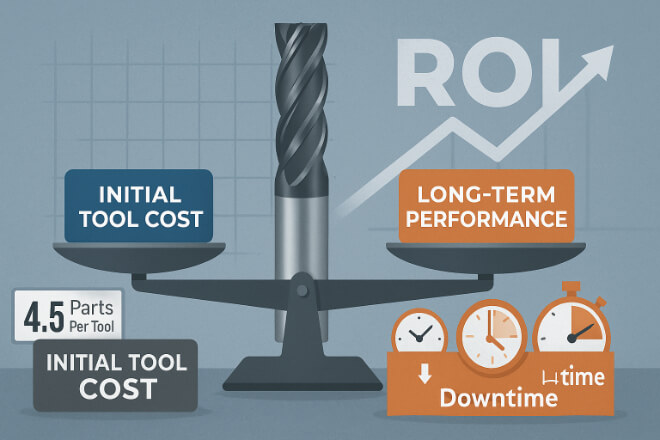

コスト vs. パフォーマンス:超硬合金が選ばれる理由

確かに、タングステンカーバイド工具はHSS工具よりも高価です。しかし、本当に考慮すべきコストは、工具1本あたりのコストではなく、部品1個あたりのコストです。

詳しく見てみましょう:

超硬工具は3~10倍長持ちする可能性がある

より速い送りと速度を可能にします

ツール交換のダウンタイムを削減

廃棄部品が少なくなる

これらすべてにより、効率が向上し、総製造コストが削減されます。

特に生産性が最も重要となる高速加工環境では、超硬合金は高い投資収益率をもたらします。

HSMで超硬合金を使用する際に避けるべきよくある間違い

高速加工においてタングステンカーバイド工具を最大限に活用するには、いくつかのよくある間違いを避ける必要があります。

- 間違った切断パラメータ

超硬工具は高速回転が可能ですが、適切な設定を行わずに無理に押し込むと工具が破損する可能性があります。必ず推奨の送り速度チャートに従ってください。

- 工具の摩耗の兆候を無視する

超硬合金は長持ちしますが、いずれ摩耗します。表面仕上げの悪さやバリの多さなどの兆候を無視せず、適切なタイミングで工具を交換しましょう。

- 不適切な工具の保持

工具ホルダーが緩んでいたり、バランスが悪かったりすると、チャタリングや振れが発生します。剛性を高めるには、焼きばめ、コレット、または油圧ホルダーを使用してください。

- 冷却剤を正しく使用していない

超硬合金はドライカットにも対応しますが、適切なクーラントを使用することで、過酷な加工においても工具寿命を延ばすことができます。ミストクーラントやスピンドルスルークーラントは、熱管理に役立ちます。

- 定期検査を省略する

摩耗、エッジの欠け、コーティングの状態を監視します。定期的な検査とメンテナンスにより、一貫性が向上し、故障リスクが軽減されます。

最後に

1 秒、1 ミクロン単位の精度が求められる高速加工において、炭化タングステン切削工具は比類のない性能を発揮します。

硬度、耐熱性、耐摩耗性に優れているため、精度を犠牲にすることなくスピードを求める現代のメーカーにとって最適な選択肢となっています。

初期投資は高速度鋼工具よりも高くなる可能性がありますが、工具寿命、部品品質、サイクルタイムの短縮といった長期的なメリットを考えると、高速操作には超硬工具の方が賢明な選択肢となります。

高速プロセス用のツールを選択するときは、次の点に注意してください。高速切断は、ツールが対応できる場合にのみ機能します。

高性能を追求したプレミアムカーバイド工具については、 リトプズ 高速加工の要求を満たすように構築されたソリューションを探ります。