如何实现轴与碳化钨衬套之间的精密配合

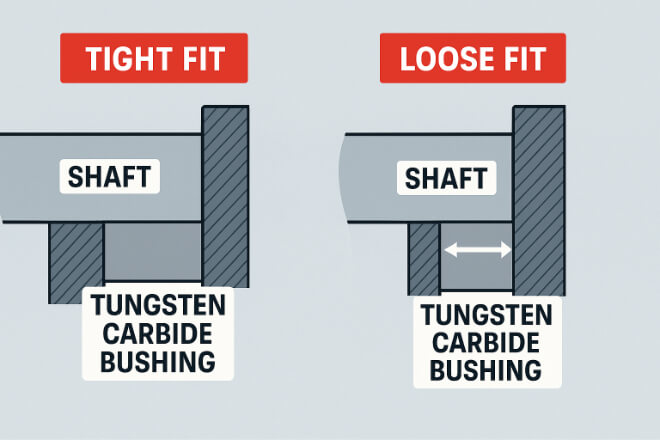

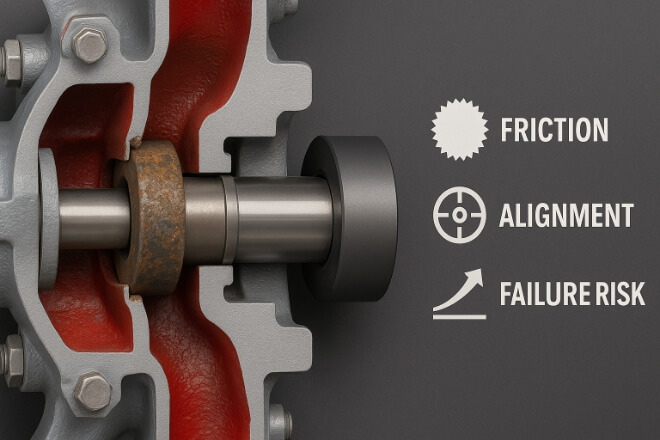

In high-performance machinery, the fit between the shaft and the tungsten carbide bushing determines how efficiently and reliably the system operates. A precision fit ensures correct alignment, minimizes friction, prevents vibration, and extends the lifespan of both the shaft and the bushing. Even if the bushing is made from high-quality tungsten carbide, poor fitting can […]

了解碳化钨衬套的公差和表面光洁度

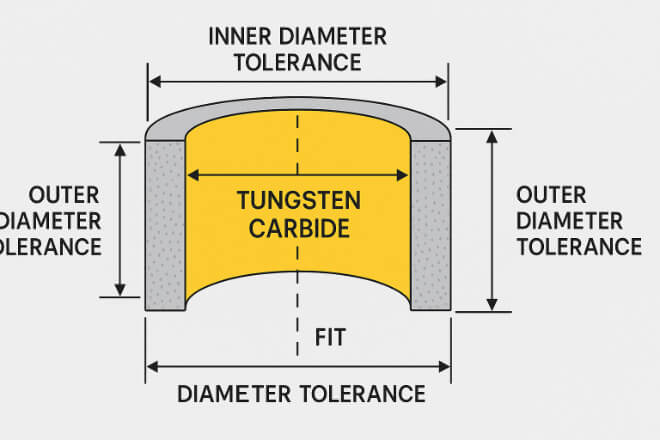

Tungsten carbide bushings are critical components in rotating machinery. They support shafts, control alignment, and minimize wear under high-pressure or high-speed conditions. While most engineers focus on material hardness and composition, tolerances and surface finishes often determine whether a bushing will succeed or fail in real operation. Small differences in dimensional accuracy or roughness can […]

如何防止碳化钨衬套腐蚀和点蚀

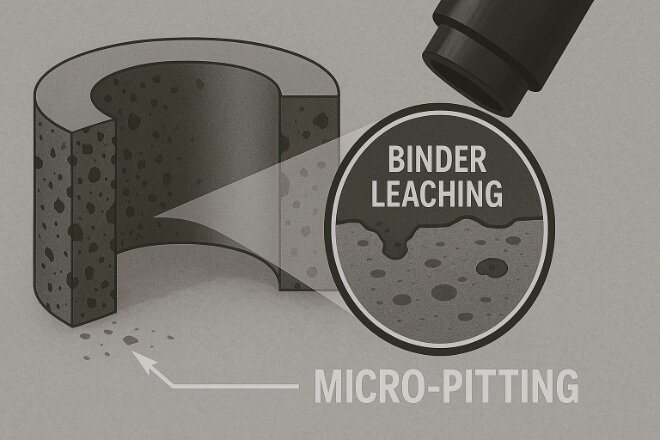

Tungsten carbide bushings are known for their hardness and wear resistance, making them vital in pumps, compressors, and high-load rotating systems. However, corrosion and pitting remain two major threats that reduce service life — especially in chemical, marine, or wet process environments. If corrosion is left unchecked, the binder phase (nickel or cobalt) begins to […]

延长碳化钨衬套寿命的维护技巧

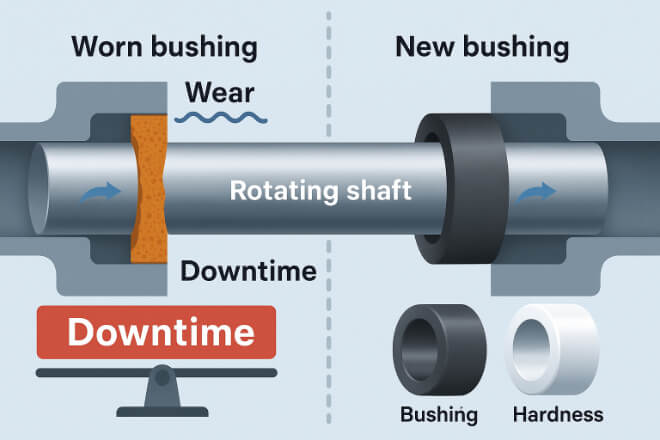

Tungsten carbide bushings are among the most durable components used in pumps, compressors, turbines, and industrial machinery. Their hardness and wear resistance make them ideal for demanding environments. However, even the toughest materials need proper maintenance to deliver long-term performance. Regular inspection, correct lubrication, and suitable operating conditions can significantly extend the lifespan of tungsten […]

如何检查碳化钨衬套的磨损或损坏

Tungsten carbide bushings are known for their exceptional hardness and wear resistance, but even the strongest materials can deteriorate over time. Regular inspection helps detect early signs of wear, cracking, or corrosion before they cause system failures. If inspection is ignored, bushings may seize, increase vibration, or damage shafts — all of which lead to […]